A kind of coating composition and preparation method thereof

A composition and coating technology, which is applied in asphalt coatings, chloroprene homopolymer coatings, coatings, etc., can solve the problems of low solid content, high cost, and large latex content, and achieve high impervious pressure, High elongation at break and low transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

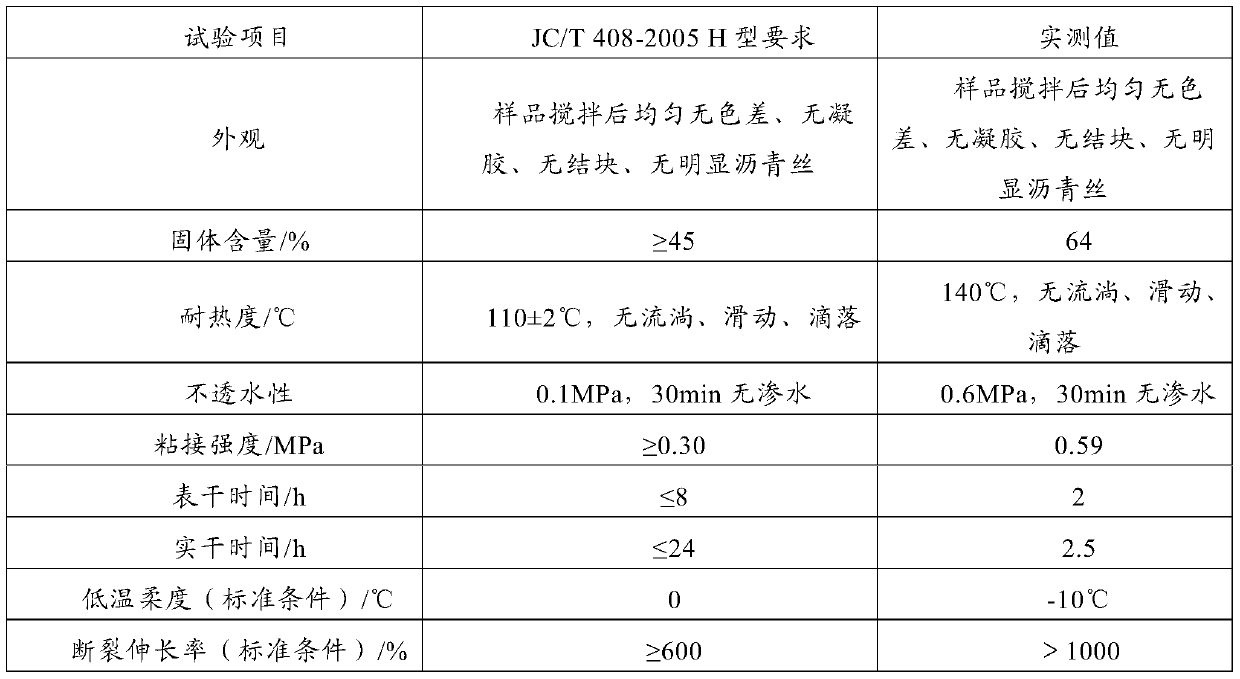

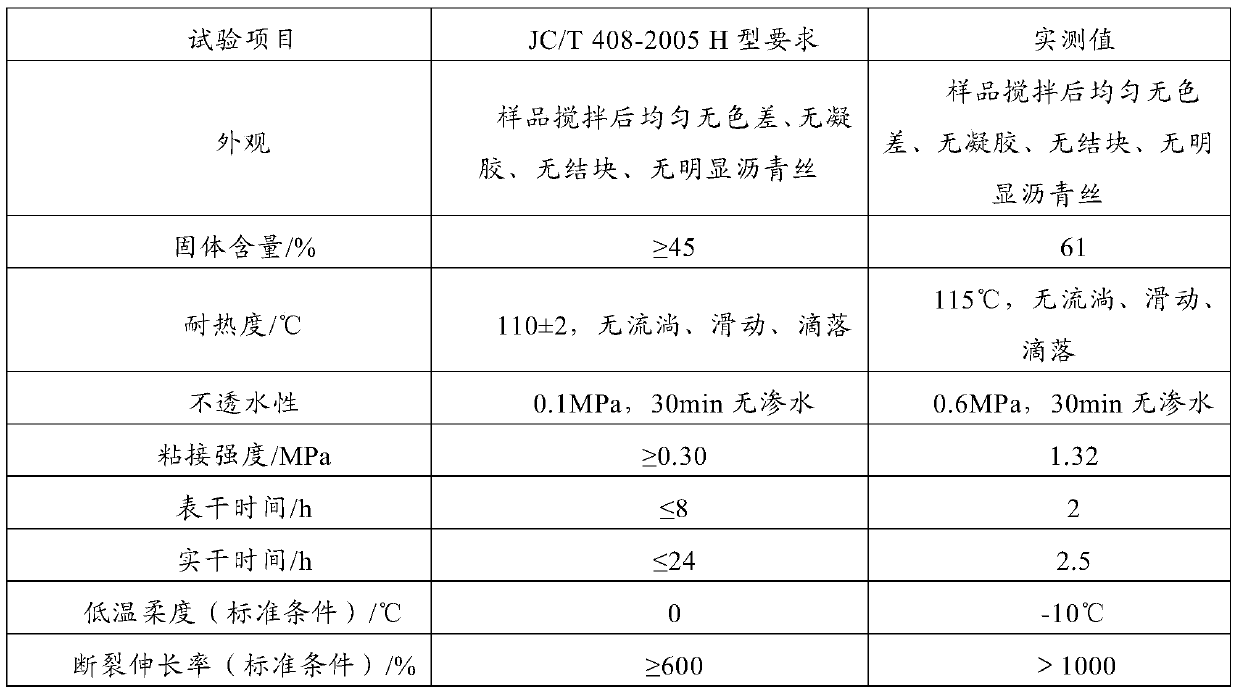

Examples

Embodiment 1

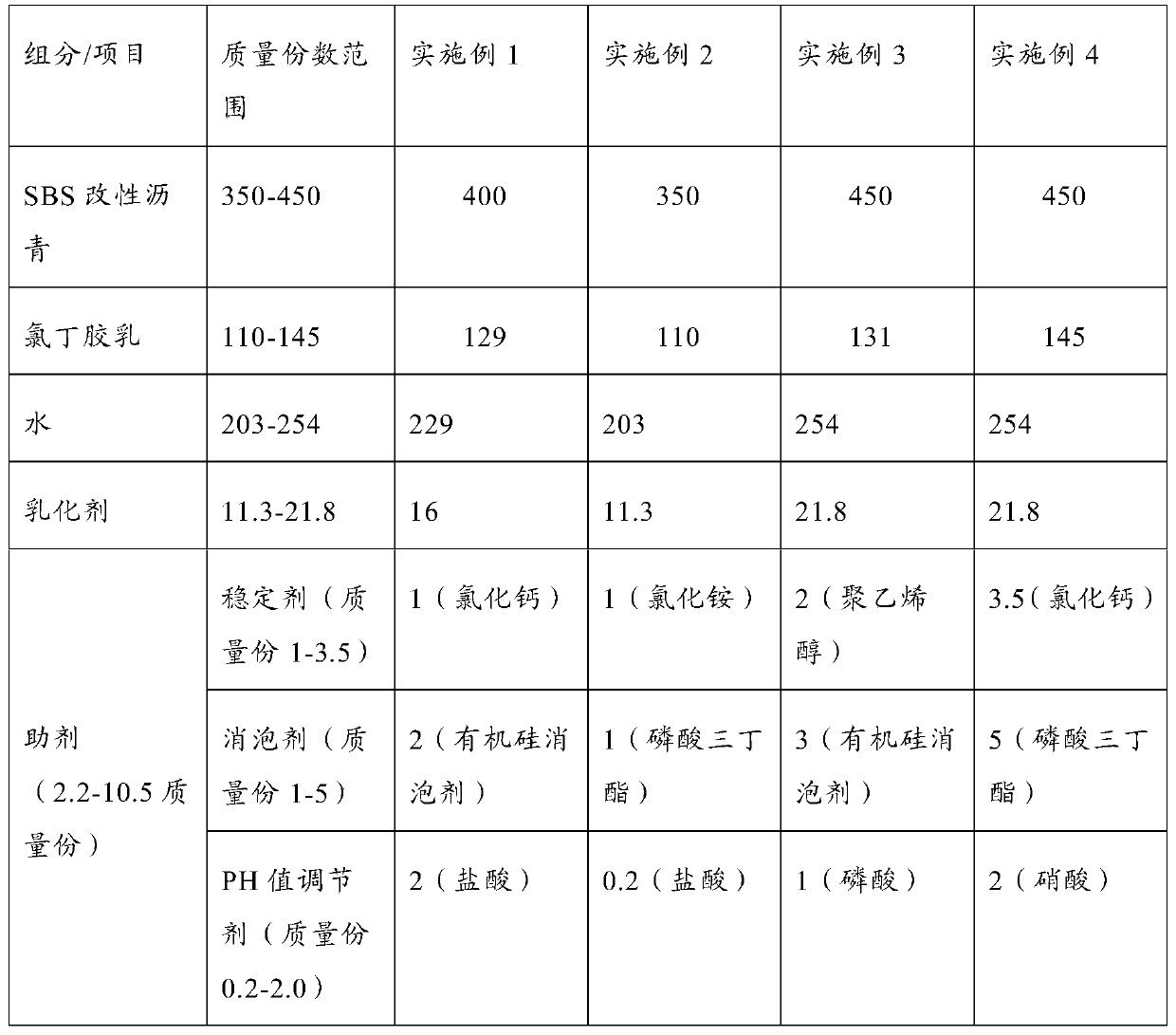

[0043] This embodiment provides a kind of coating composition and preparation method thereof, and coating composition comprises the component as shown in Table 1;

[0044] Wherein, the softening point of the SBS modified asphalt is 56° C., the ductility is 45 cm, the penetration is 41; the rotational viscosity is 500 mPa·s.

[0045] Component and mass fraction of the coating composition prepared by the embodiment 1-4 of table 1

[0046]

[0047] The preparation method of coating composition is as follows:

[0048] To prepare soap:

[0049] Add the emulsifier, stabilizer, and neoprene latex into water to obtain a mixture according to the above-mentioned parts by mass, heat the mixture to 50°C, and adjust the pH to 1.5 with a pH regulator to obtain a soap liquid;

[0050] emulsification:

[0051] The SBS modified asphalt is heated to 165° C., and the SBS modified asphalt and defoamer are slowly added to the soap solution according to the above mass fractions for emulsifica...

Embodiment 2

[0057] This embodiment provides a kind of coating composition and preparation method thereof, and coating composition comprises the component as shown in Table 1;

[0058] Wherein, the softening point of the SBS modified asphalt is 70° C., the ductility is 21 cm, the penetration is 65; the rotational viscosity is 400 mPa·s.

[0059] The preparation method of coating composition is as follows:

[0060] To prepare soap:

[0061] Add the emulsifier, stabilizer, and neoprene latex into water to obtain a mixture according to the above mass parts, heat the mixture to 65°C, and adjust the pH to 3.5 with a pH regulator to obtain a soap liquid;

[0062] emulsification:

[0063] The SBS modified asphalt is heated to 150° C., and the SBS modified asphalt and the defoamer are slowly added to the soap solution according to the above mass fractions for emulsification.

[0064] The emulsification adopts a colloid mill, the rotation speed of the colloid mill is 1000r / min, and the emulsific...

Embodiment 3

[0069] This embodiment provides a kind of coating composition and preparation method thereof, and coating composition comprises the component as shown in Table 1;

[0070] Wherein, the softening point of the SBS modified asphalt is 60° C., the ductility is 30 cm, the penetration is 50, and the rotational viscosity is 200 mPa·s.

[0071] The preparation method of coating composition is as follows:

[0072] To prepare soap:

[0073]Add the emulsifier, stabilizer, and neoprene latex into water to obtain a mixture according to the above-mentioned parts by mass, heat the mixture to 60°C, and adjust the pH to 2.0 with a pH regulator to obtain a soap liquid;

[0074] emulsification:

[0075] The SBS modified asphalt is heated to 175° C., and the SBS modified asphalt and defoamer are slowly added to the soap solution according to the above mass fractions for emulsification.

[0076] The emulsification adopts a colloid mill, the rotation speed of the colloid mill is 4000r / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com