Continuous SLM equipment

An equipment and platform technology, applied in the field of continuous SLM equipment, can solve the problems of small forming size that cannot meet the manufacturing needs of large parts, expensive optical components, and increase equipment manufacturing costs, etc., to improve utilization and forming efficiency, achieve Continuity, the effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

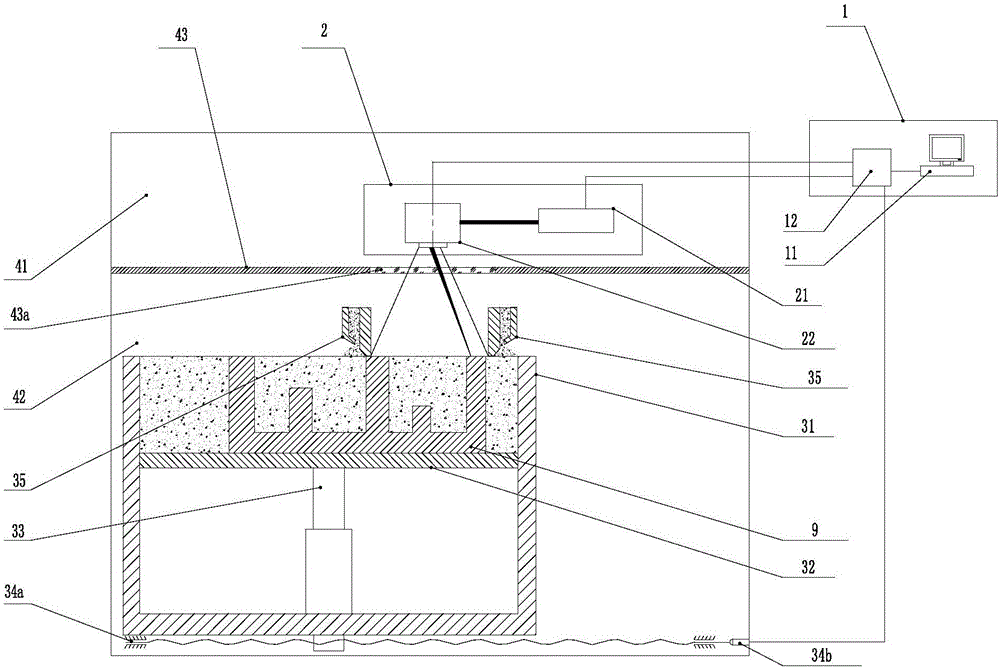

[0018] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the continuous SLM equipment of this embodiment includes a control system 1, a galvanometer scanning system 2 and a forming system, and the forming system includes a forming platform 31, which is located on the forming platform 31. The forming substrate 32 and the substrate driving mechanism 33 for driving the forming substrate 32 to move in the vertical direction, the galvanometer scanning system 2 and the substrate driving mechanism 33 are respectively connected with the control system 1; the forming system also includes a driving mechanism for driving the forming The platform driving mechanism that platform 31 moves along horizontal direction, described platform driving mechanism is connected with control system 1; Control system 1 can comprise industrial computer 11 and motion control card 12, and industrial computer 11 is connected with motion control card 12 by PCI slot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com