Two-step aligning adjusting-type full-automatic industrial sewing machine

An industrial sewing machine, fully automatic technology, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of long standby time and affecting the working efficiency of industrial sewing machines, and achieve the effect of convenient implementation, avoiding standby time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

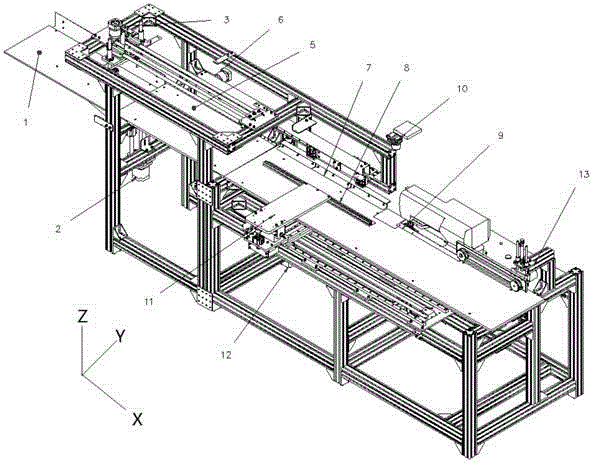

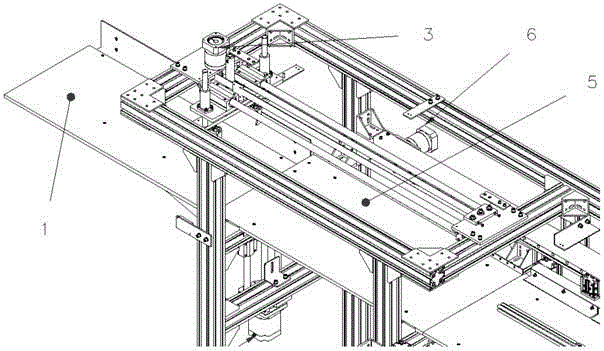

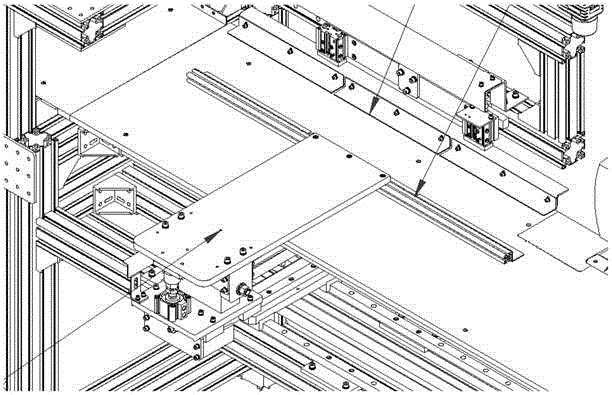

[0026] see Figure 1-Figure 5 , a two-step alignment adjustment type full-automatic industrial sewing machine, including a feeding mechanism sequentially connected along the X direction, a pre-adjustment mechanism, a visual adjustment mechanism, and a head assembly; the feeding structure includes a feeding rack 1, the The material rack 1 is stacked with pieces of cloth to be sewed, and the material rack feeds the cloth successively under the action of the first motor 2, and the feeding interval is set according to the thickness of the cloth; Can move laterally; the pre-adjustment mechanism includes a preset material area 5, the head of the preset material area is provided with a sensor group, the sensor group senses the position of the front edge of the cloth, and feeds back a signal to the pre-adjustment power mechanism, The pre-adjustment po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com