Flame-retardant breathable warp-knitted safe protective clothing fabric and preparation method thereof

A safety protection and clothing technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of single function of protective clothing fabrics, complicated preparation methods, and can only be used in fire scenes, and achieve continuous and uninterrupted production operations. The effect of strong practicability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

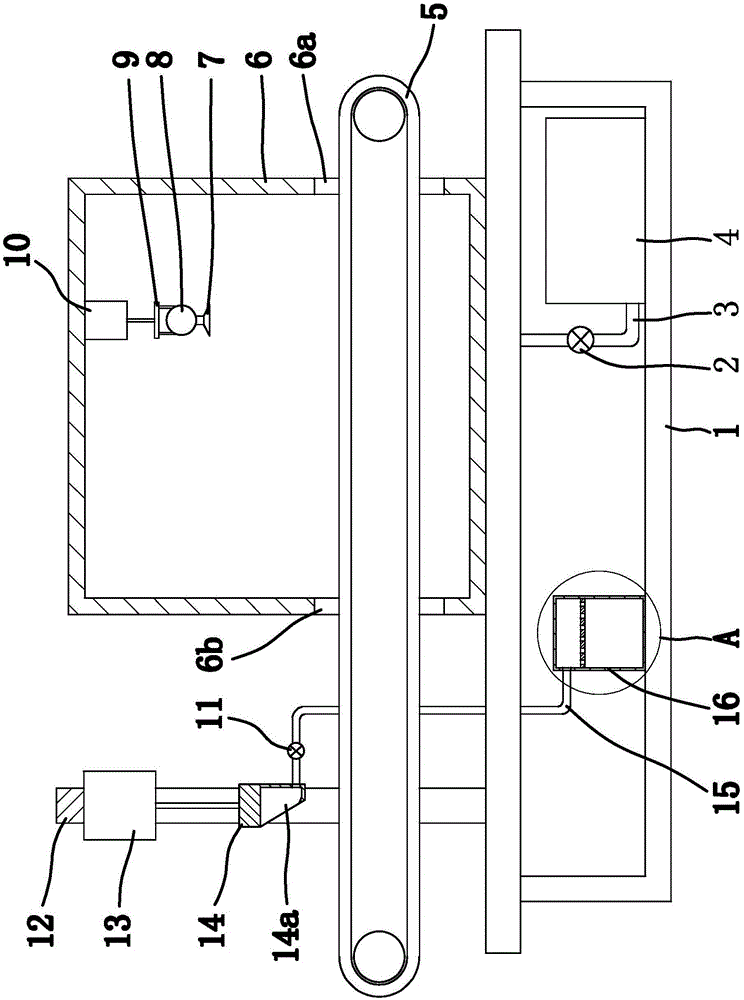

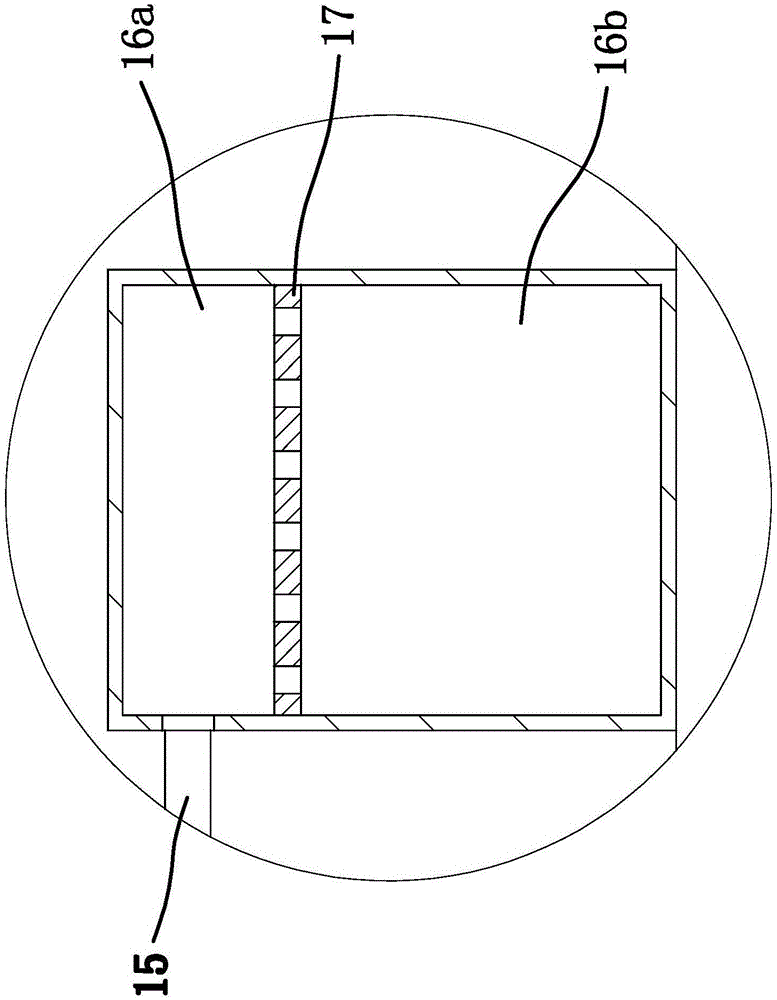

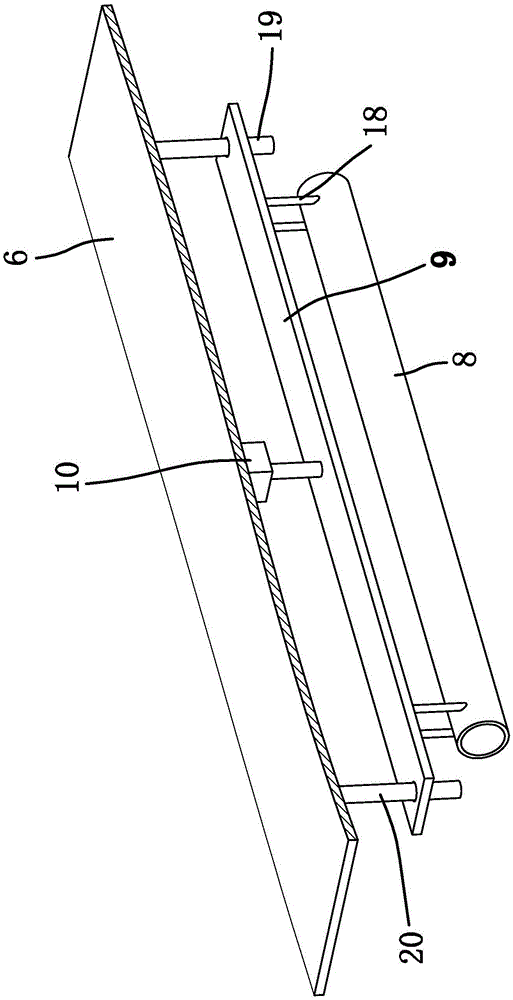

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0044] The flame-retardant breathable warp-knitted safety protective clothing fabric includes a base cloth layer and an adhesive layer, and the adhesive layer is composed of the following components in parts by weight: 60-80 parts of polytetrafluoroethylene concentrated dispersion, 20-30 parts of nitrile rubber 3-8 parts of magnesium oxide, 3-8 parts of zinc oxide, 5-10 parts of caprylic acid ester, 2-4 parts of cross-linking agent, 1-1.5 parts of softener, 0.2-0.6 parts of antioxidant, using the After the composition, the adhesion layer is mainly composed of polytetrafluoroethylene concentrated dispersion, and an appropriate amount of nitrile rubber, magnesium oxide, zinc oxide, glycerin caprylate, crosslinking agent, soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com