Overall unit cooling system for wind generating set, control method for overall unit cooling system, and wind generating set

A technology for wind turbines and heat dissipation systems, applied in wind turbine components, wind engine control, wind engines, etc., can solve the problems of wind farms with large wind and sand, unstable air supply, and overheating of heating components. To achieve the effect of ensuring normal operation, avoiding overheating and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

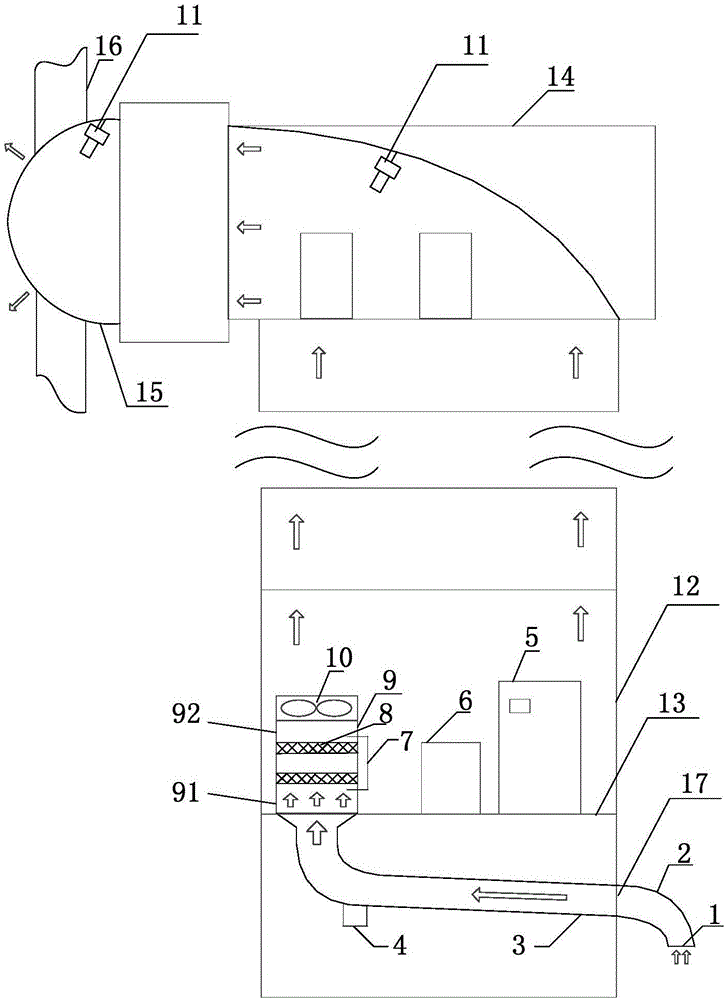

[0025] Such as figure 1 As shown, the wind power generating set with the complete cooling system of the embodiment of the present invention includes a tower 12 , a nacelle 14 on the tower 12 and a hub 15 on which fan blades 16 are arranged.

[0026] The heat dissipation system of the whole machine includes an air inlet 17 arranged on the wall of the tower 12 , a fan 10 and an air box 9 arranged inside the tower 12 . The air box 9 has an air inlet end 91 open downward and an air outlet end 92 opposite to the air inlet end 91. An air handling system 8 is arranged in the air box 9, and the air handling system 8 connects the air inlet end 91 and the air outlet end 92. Separated from each other, the air inlet end 91 is connected to the air inlet 17 through the air guide pipe 3 , and the fan 10 is arranged on the air outlet end 92 . The bellows 9 is preferably arranged on the main control platform 13 inside the tower 12 .

[0027] The bellows 9 can be designed in a square or cylin...

Embodiment 2

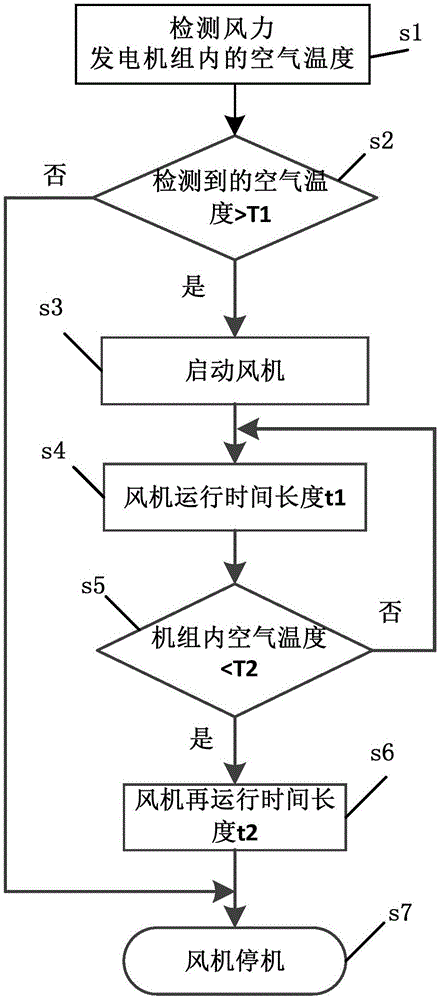

[0051] Embodiment 2 is an embodiment of the control method for the cooling system of the whole machine of the present invention, including the following steps:

[0052] First in step s1, the temperature sensor 11 detects the air temperature in the wind power generating set and transmits the temperature signal to the main control system 5;

[0053] Then in step s2, the main control system 5 compares the air temperature in the wind power generating set with the predetermined first boundary temperature T1, and if the air temperature is greater than the first boundary temperature T1, then execute step s3;

[0054] In step s3, the main control system 5 activates the fan 10 to perform heat dissipation.

[0055] Further, in order to avoid frequent starting of the fan 10 and to protect the fan 10, after the fan 10 is started, the following steps are also included:

[0056] Step s4, make the fan 10 run for a predetermined first time length t1;

[0057] Then in step s5, the main contr...

Embodiment 3

[0072] The third embodiment provides a wind power generating set, which includes the cooling system for the whole machine according to the first embodiment.

[0073] The structure, principle and beneficial effects of the heat dissipation system of the wind power generating set are as described in the first embodiment above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com