Plunger pair lubricating and cooling structure for swash plate type plunger pump

A swash plate type plunger pump, lubricating and cooling technology, applied in variable capacity pump components, components of pumping devices for elastic fluid, pump components, etc., can solve the problem of reduced life value of lift pumps and increased gap leakage Increased cooling and heat transfer effects, low agitation heat generation, and enhanced lubrication and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

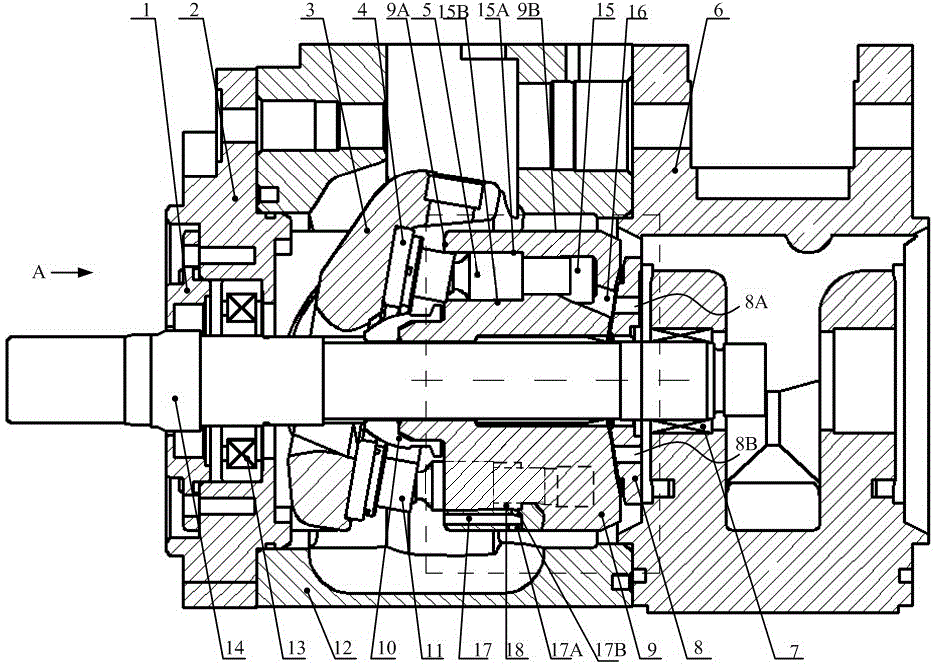

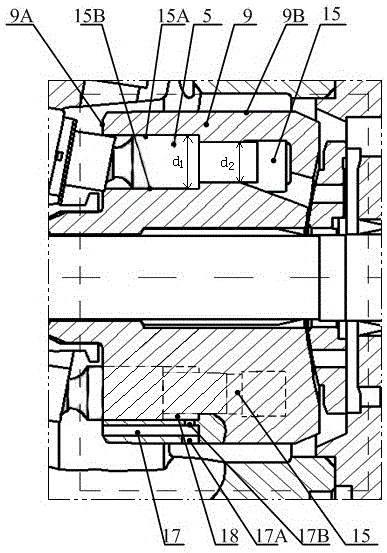

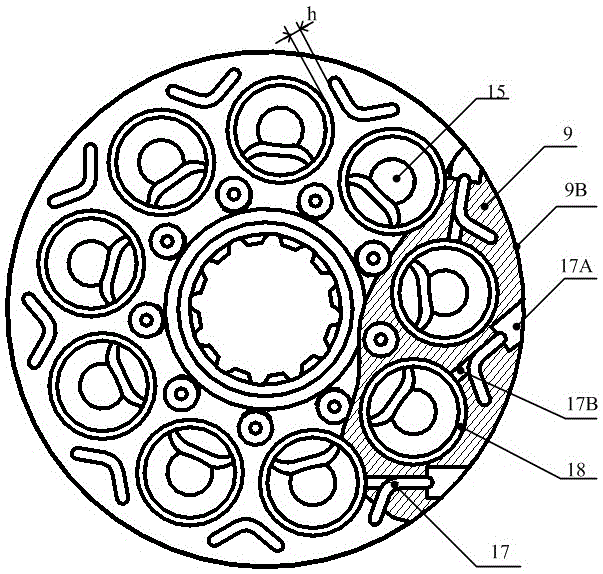

[0036] Such as figure 1 As shown, a plunger pair lubricating and cooling structure of a swash plate type plunger pump includes a cylinder 9 located in the plunger pump body and a plurality of plungers 5, and a number of annular arrays are arranged on the front end of the cylinder 9. The plunger hole 15 is driven by the rotation of the cylinder body 9. The plunger 5 reciprocates and slides in the plunger hole 15 through the swash plate and the sliding shoe; In the hole 15, there is an oil channel system for cooling and lubricating the hole wall. The bottom of the plunger hole 15 is connected with the distribution plate 8 through the waist-shaped hole 16 and communicates with the low-pressure oil suction area 8A and the high-pressure oil discharge area 8B of the flow plate 8. The plunger hole 15 is a stepped cavity with two diameters and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com