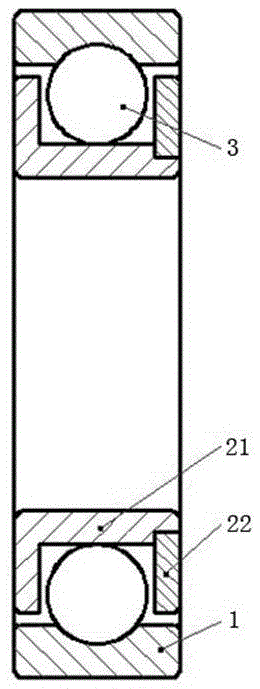

Bearing inner ring and full-ball bearing

A bearing inner ring and full ball bearing technology, applied in the field of bearings, can solve the problems of easy damage and poor stability of the inner ring, and achieve the effects of stable rotation, improved bearing capacity, and eliminated friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0017] Embodiment 2 of the full ball bearing of the present invention: the difference from Embodiment 1 is that the inner ring of the bearing is set as a whole, and the shape of the cross-section passing the axis is a U-shaped groove structure, and one side of the groove wall is provided with a Fill the gap of the steel ball.

Embodiment 3

[0018] Embodiment 3 of the full ball bearing of the present invention: the difference from Embodiment 1 lies in that the right side of the retaining ring of the inner ring is an inclined surface.

[0019] Embodiment 4 of the full ball bearing of the present invention: the difference from Embodiment 1 is that the retaining ring connection structure is respectively provided on the right end surface of the inner ring body and the connection hole on the inner ring retaining ring, and the inner ring retaining ring and The inner ring body is connected by connecting screws.

Embodiment 1

[0021] Embodiment 1 of the bearing inner ring of the present invention: the structure of the bearing inner ring in the above full ball bearing embodiment is the same, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com