Foamed ceramic composite floor-heating brick and preparation method thereof

A technology of foamed ceramics and foamed ceramic plates, which is applied in the field of building decoration materials, can solve problems such as low installation efficiency and complicated manufacturing process, and achieve the effects of improving efficiency, high manufacturing efficiency, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

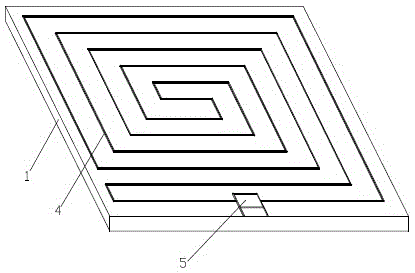

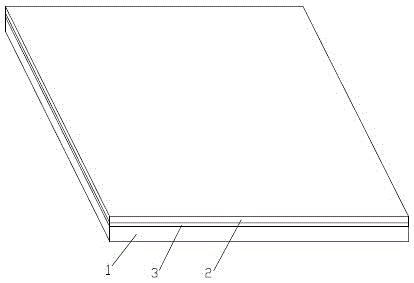

[0023] figure 1 , figure 2 Shown is the foamed ceramic composite floor heating tile provided by the present invention, including a foamed ceramic plate 1 and a building decoration layer 2 located on the foamed ceramic plate 1, and a bonding layer is arranged between the foamed ceramic plate 1 and the building decoration layer 2 3. The upper surface of the foamed ceramic plate 1 is provided with a wire groove 4, and a carbon fiber heating wire is arranged in the wire groove 4. Through the compounding of the foamed ceramic board 1 and the building decoration layer 2, the foamed ceramic board 1 has mutually independent and non-connected air holes, and the foamed ceramic board 1 of the composite brick is quickly combined and fixed with the ground cement, and the installation and bonding performance is strong. Compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com