A method for measuring the deviation of laser beam from powder cone in laser cladding

A measurement method, laser cladding technology, applied in the direction of measurement devices, metal material coating technology, instruments, etc., can solve the problems of inability to quantitatively reflect the degree of deviation, high risk of visual inspection, long debugging feedback cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

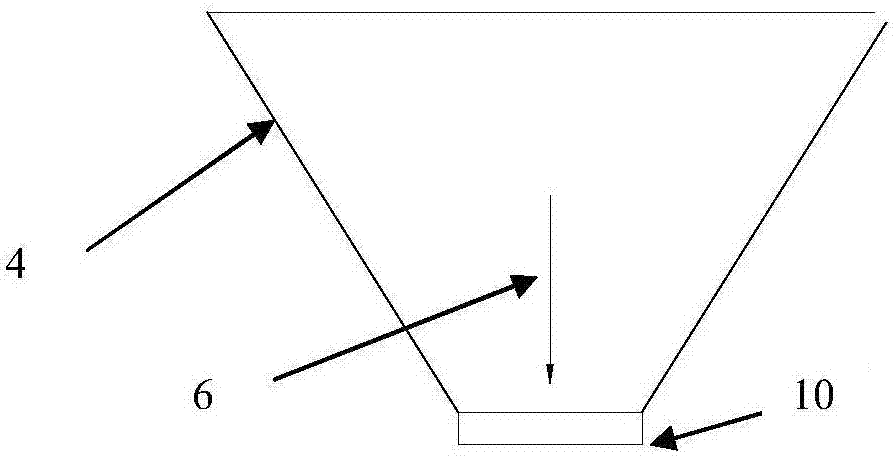

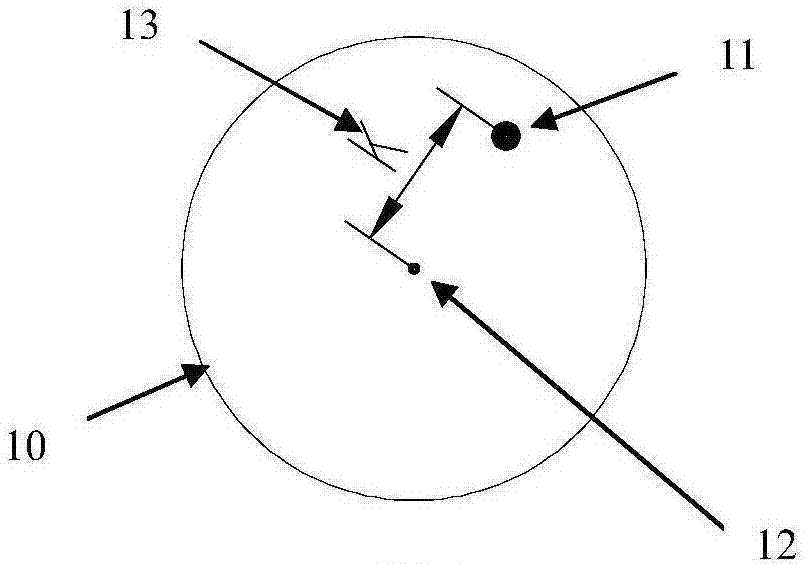

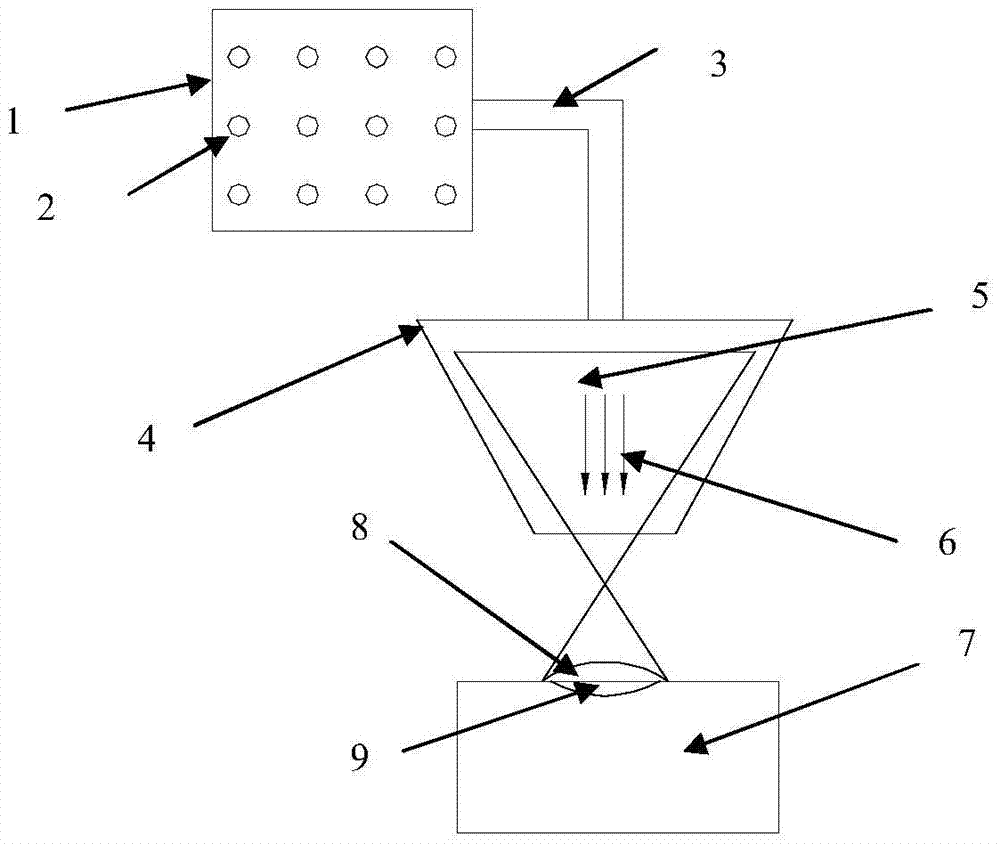

Method used

Image

Examples

Embodiment Construction

[0024] Taking the 316L stainless steel laser cladding test as an example, the specific implementation of the technical plan is as follows:

[0025] 1. Add stainless steel powder;

[0026] 2. Clamp the 5mm thick 316L steel plate on the test bench, and fasten the pressure plate with screws;

[0027] 3. Compile the cladding test program, positive defocus cladding, laser power 700W, travel speed 0.03m / s, head height 12mm; travel path 50mm×50mm (two perpendicular directions), powder feeding volume 10g / min. run the program;

[0028] 4. Cut metallographic: cut cladding parts with grinding wheel in two vertical directions, and polish with sandpaper;

[0029] 5. Smear the corrosion section with passivation paste, observe and measure the deviation degree of the centers of the two samples (corrosion metallography); calculate the deviation degree of the laser beam;

[0030] 6. The deviation calculation method is as follows:

[0031] Let the offsets between the cladding layer and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com