Potential energy change based method for quantitatively characterizing packing segregation state of particles after falling

A quantitative characterization and particle technology, applied to the analysis of materials, instruments, etc., can solve the problems of particle segregation lack of general rules, and achieve the effects of reduced energy consumption, convenient operation, and small reading error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

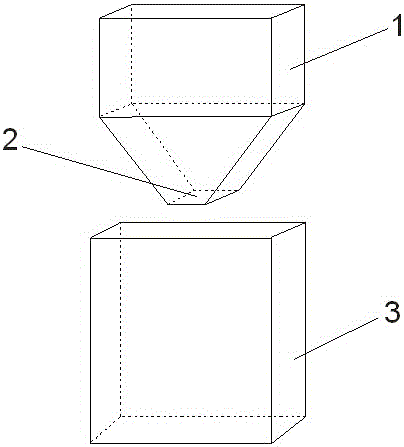

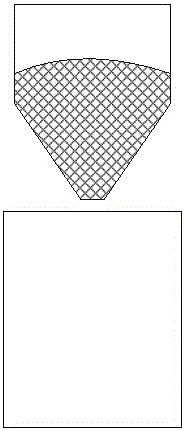

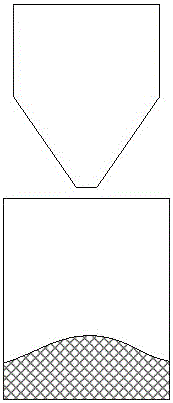

[0037]1) Establish a batching model consisting of the distributor 1 and the charging tank 3 to simulate the falling process of 300g of aluminum oxide, in which the length L1=200mm, the height L2=250mm, and the width L3=28mm of the charging tank 3, The length L4 of the discharge opening 2 of the distributor 1 is 28 mm, and the width L5 is 14 mm, and the opposite side walls of the discharge opening 2 of the distributor 1 form an angle of 50° with the horizontal direction.

[0038] 2) Establish particle models with two particle sizes, in which the two particle diameters are set to 3mm and 6mm respectively, the particle Young's modulus is set to 375GPa, the particle Poisson's ratio is set to 0.22, and the particle density is set to 2099kg / m 3 , The friction coefficient between the particles and the wall is set to 0.4, the restitution coefficient between the particles and the wall is set to 0.7, the friction coefficient between the particles is set to 0.5, the restitution coefficien...

Embodiment 2

[0043] 1) Establish a model consisting of the distributor 1 and the charging tank 3 to simulate the falling process of 300g of aluminum oxide, wherein the length L1=200mm, the height L2=250mm, and the width L3=28mm of the charging tank 3, The length L4 of the discharge opening 2 of the distributor 1 is 28 mm, and the width L5 is 14 mm, and the opposite side walls of the discharge opening 2 of the distributor 1 form an angle of 50° with the horizontal direction.

[0044] 2) Establish particle models with two particle sizes, in which the particle diameters are set to 3mm and 6mm respectively, the particle Young's modulus is set to 375GPa, the particle Poisson's ratio is set to 0.22, and the particle density is set to 2099kg / m 3 , The friction coefficient between the particles and the wall is set to 0.4, the restitution coefficient between the particles and the wall is set to 0.7, the friction coefficient between the particles is set to 0.5, the restitution coefficient between the...

Embodiment 3

[0049] 1) Establish a model consisting of distributor 1 and charging tank 3 to simulate the falling process of 300g of aluminum oxide, where the length L1=200mm, height L2=250mm, width L3=28mm of charging tank 3, The length L4=28mm of the feed port 2, the width L5=14mm, and the opposite side walls of the feed port 2 of the distributor 1 form an angle of 50 degrees with the horizontal direction.

[0050] 2) Establish particle models with two particle sizes, in which the particle diameters are set to 3mm and 6mm respectively, the particle Young's modulus is set to 375GPa, the particle Poisson's ratio is set to 0.22, and the particle density is set to 2099kg / m 3 , The friction coefficient between the particles and the wall is set to 0.4, the restitution coefficient between the particles and the wall is set to 0.7, the friction coefficient between the particles is set to 0.5, the restitution coefficient between the particles is set to 0.6, 3mm particle quality: 6mm The mass of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com