Manufacturing method of optical microstructure, processing machine cabinet and light guide plate die

An optical microstructure and manufacturing method technology, applied in the directions of light guides, optics, optical components, etc., can solve the problem of the decrease in the processing yield of optical microstructures, the influence of the shape or size of optical microstructures, and the inability of a single-mode structure to meet the requirements of light guiding efficiency and other problems, to achieve the effect of improving imprint yield, optimal structural strength and variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

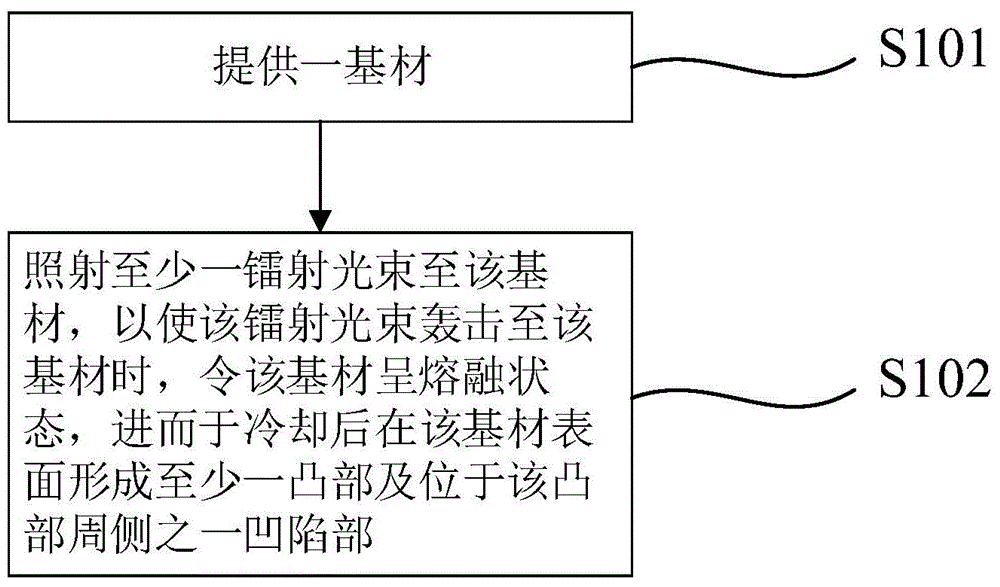

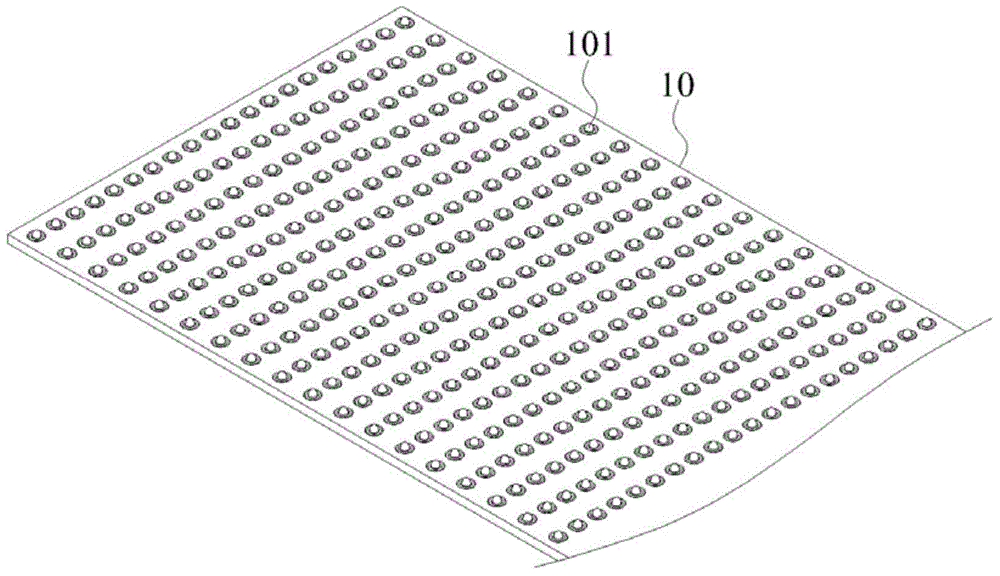

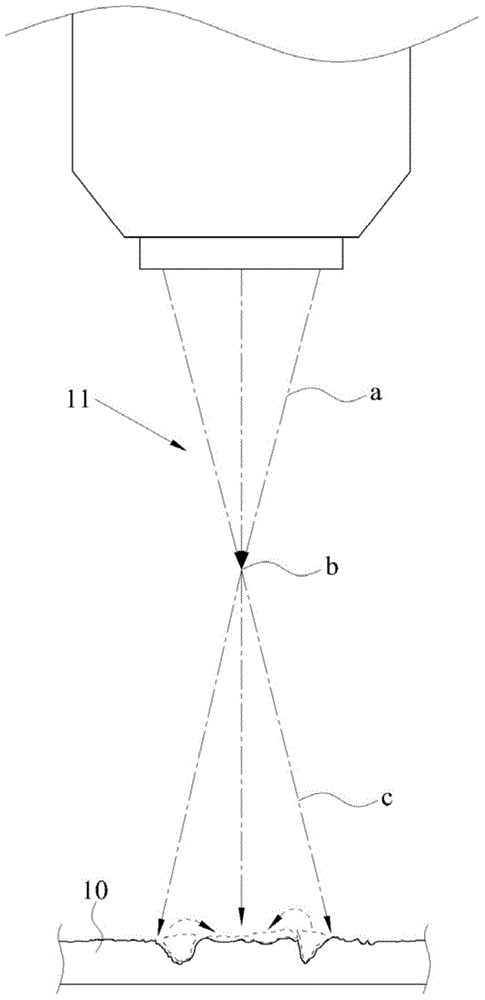

[0053] See figure 1 , 2 And 3 to 4, which are the schematic diagrams of the step flow of the embodiment 1 of the present invention, the three-dimensional schematic diagrams of the substrate after processing, and the schematic diagrams of each processing. The invention discloses a method for manufacturing an optical microstructure, which includes the following steps.

[0054] First, a substrate 10 is provided, which is step S101. Wherein, the substrate 10 has a melting point temperature C 1 . Next, as shown in step S102, at least one laser beam 11 is irradiated to the substrate 10, so that when the laser beam 11 hits the substrate 10, the substrate 10 is in a molten state, and then the substrate 10 is in a molten state after cooling. The surface of the material 10 is formed with at least one convex portion 101 and a concave portion 102 on the peripheral side of the convex portion 101. Wherein, the laser beam 11 has a processing temperature C 2 , And meet C 1 ≤C 2 ≤(1.1×C 1 ), by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com