Detection method for bridging position in metal hard mask all-in-one etching

A technology of metal hard mask and detection method, which is applied in the photoengraving process of the pattern surface, the original for photomechanical processing, optics and other directions, and can solve the problems of bridging and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

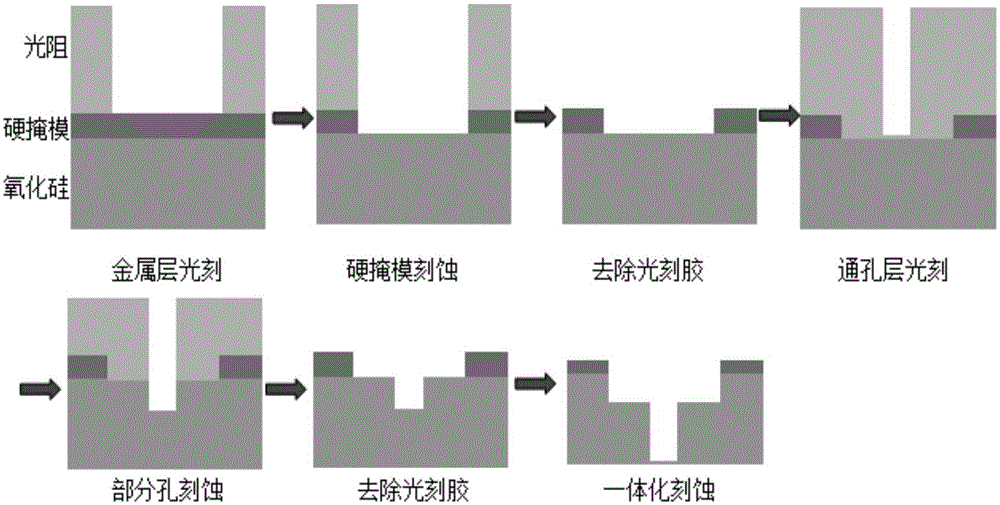

[0035] Please also see Figure 3 to Figure 9 , the detection method of the bridging position in the integrated etching of the metal hard mask in this embodiment specifically includes the following steps:

[0036] Step S01 , providing a layout to be etched with a metal hard mask.

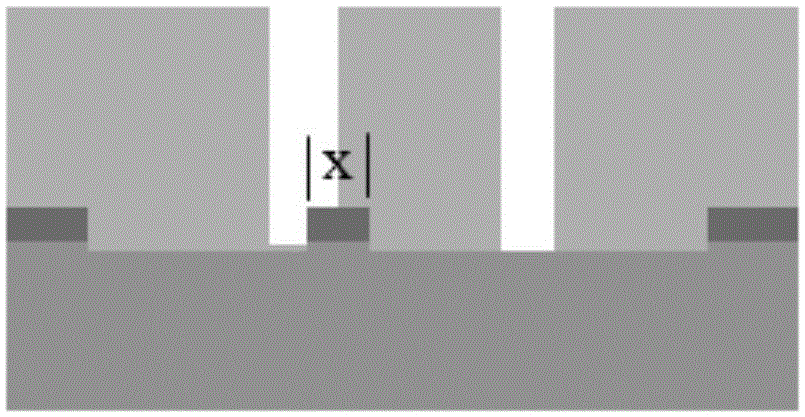

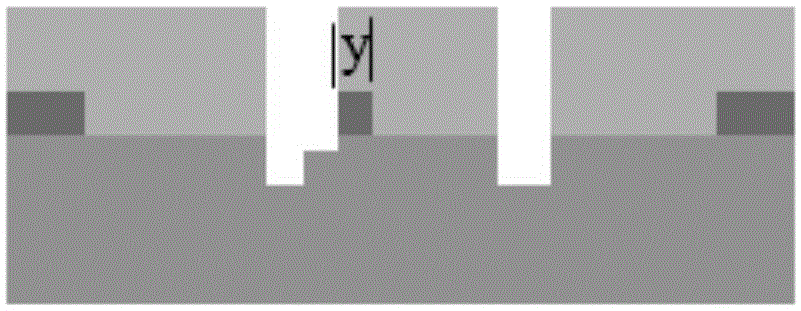

[0037] Step S02, import the optical proximity effect correction result of the metal layer in the layout, and simulate it to obtain the simulated pattern of the metal layer after photolithography, such as Figure 4 As shown, the spacing between adjacent metal layers at A after simulated photolithography is 100 nm.

[0038] Wherein, the optical proximity effect correction result of the metal layer can be obtained according to the prior art. In this embodiment, simulation is preferably carried out according to the correction result of the optical proximity effect of the metal layer and the target result of the photolithography of the metal layer, that is, the theoretical result, to obtain a simulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com