Quick construction method for No. 0 section of prestressed concrete beam type bridge

A technology of concrete beams and construction methods, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high-altitude operations with many procedures and long construction periods, and achieve the effects of shortening operation time, high labor efficiency, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

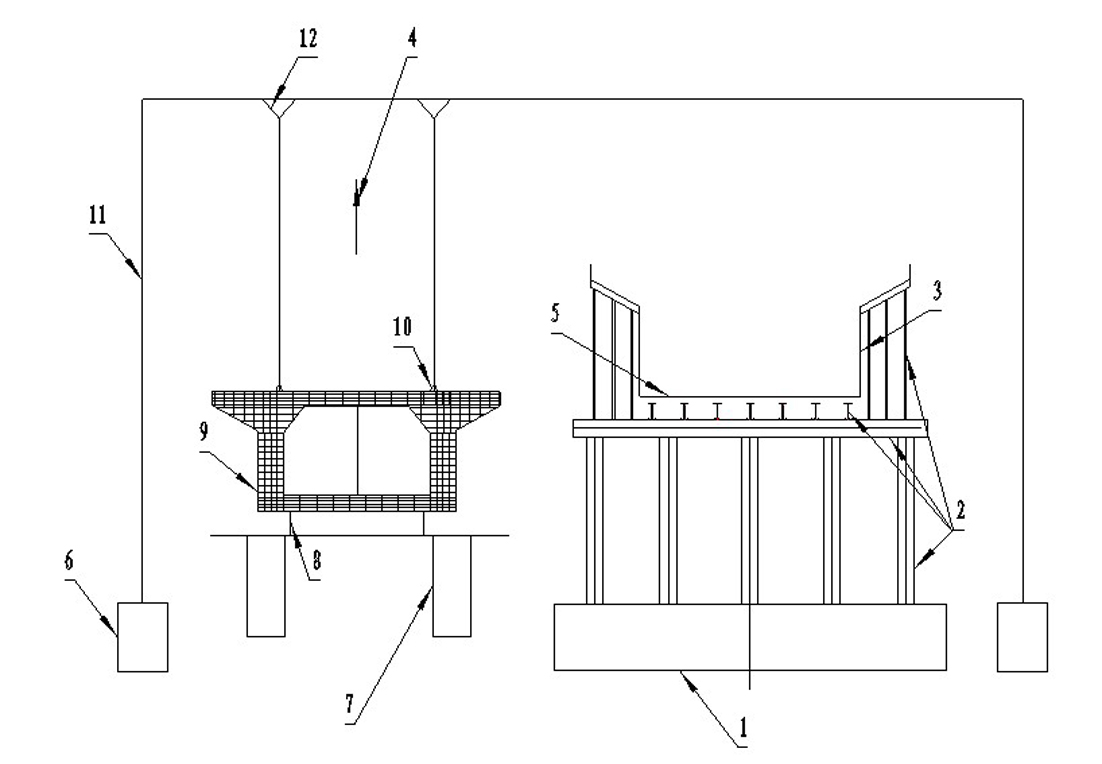

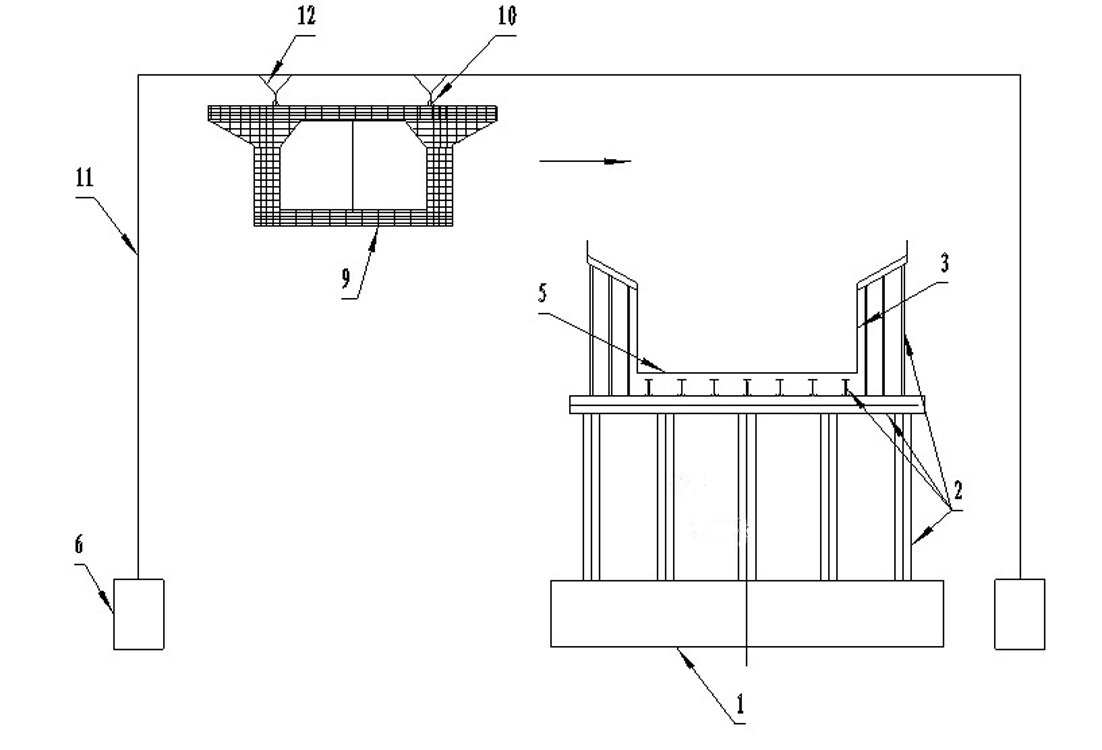

[0020] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

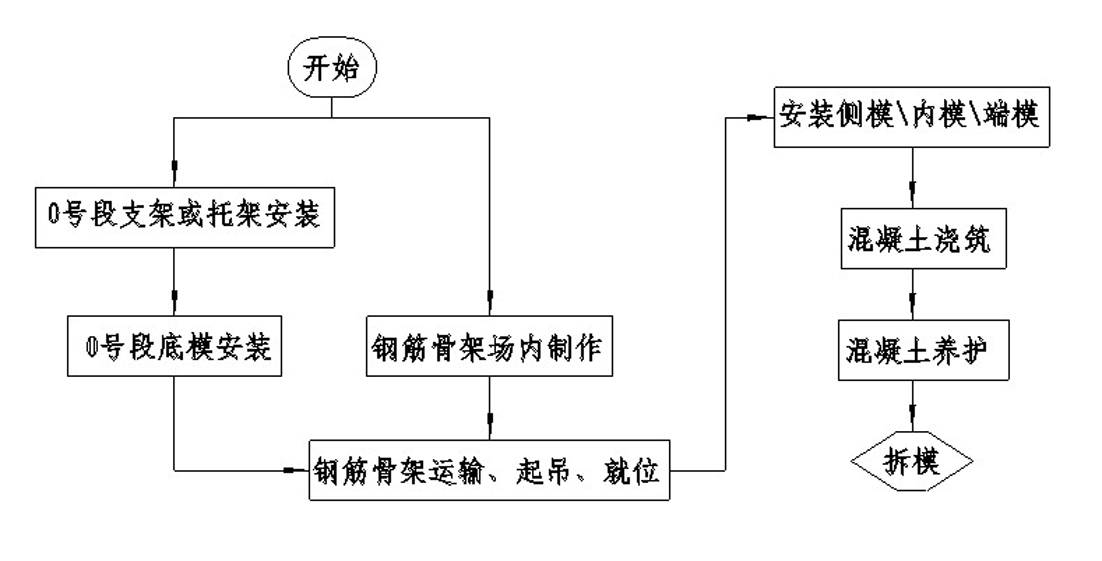

[0021] The rapid construction method of No. 0 section of prestressed concrete girder bridge, the installation of brackets or brackets and bottom formwork (including side formwork) of No. 0 section and the production of steel skeleton are parallel operations. The core content of this method is that the bracket installation is parallel to the steel skeleton During the operation, the steel bar skeleton is made and formed in the steel bar yard, and then transported and hoisted to the top of the bridge support, and then the concrete pouring and other constructions are carried out.

[0022] Take the construction process of the 10m-long No. 0 main girder on the pier top of a certain bridge as an example:

[0023] (1) Reserve the work space for steel frame production in the existing steel bar processing yard adjacent to the bridge site, ensure enough proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com