Mechanical equipment operation data active detection recorder and record method

A technology of mechanical equipment and operating data, applied in the testing of mechanical parts, time register, registering/instructing the work of the machine, etc., can solve the problems of operation data destruction, burning, high temperature, etc. Effect of remaining data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the specific implementations described here are only used to illustrate and explain the description, and are not intended to limit the present invention.

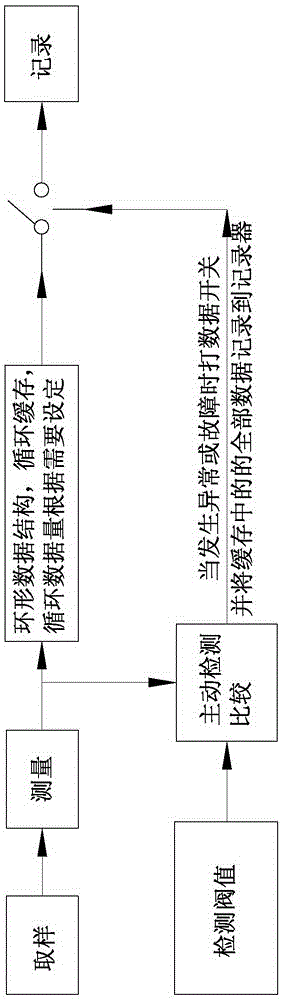

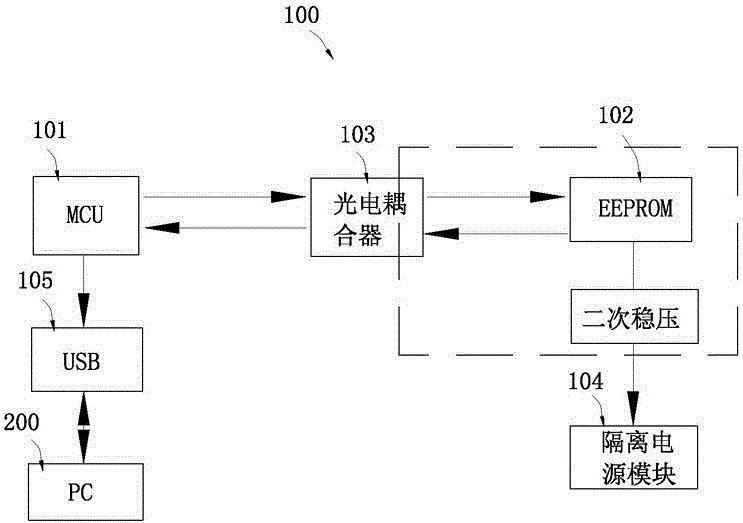

[0018] Such as figure 1 As shown, the mechanical equipment operation data active detection recorder of the present embodiment comprises:

[0019] The sampling working module uses multiple sensors to detect the real-time physical quantity reflecting the state of the equipment from the mechanical equipment to be tested, and converts it into a suitable original electrical signal, which is transmitted to the subsequent unit; the measuring module is used to test the The original electrical signal sent from the transmission is preprocessed, the interference mixed in the original electrical signal is suppressed to improve the signal-to-noise ratio, and the preprocessed electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com