Monolithic weighing system

A weighing system, one-piece technology, applied in the details of weighing equipment, weighing equipment using electromagnetic balance, weighing, etc., to solve problems such as limited reproducibility, assembly impact, assembly inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

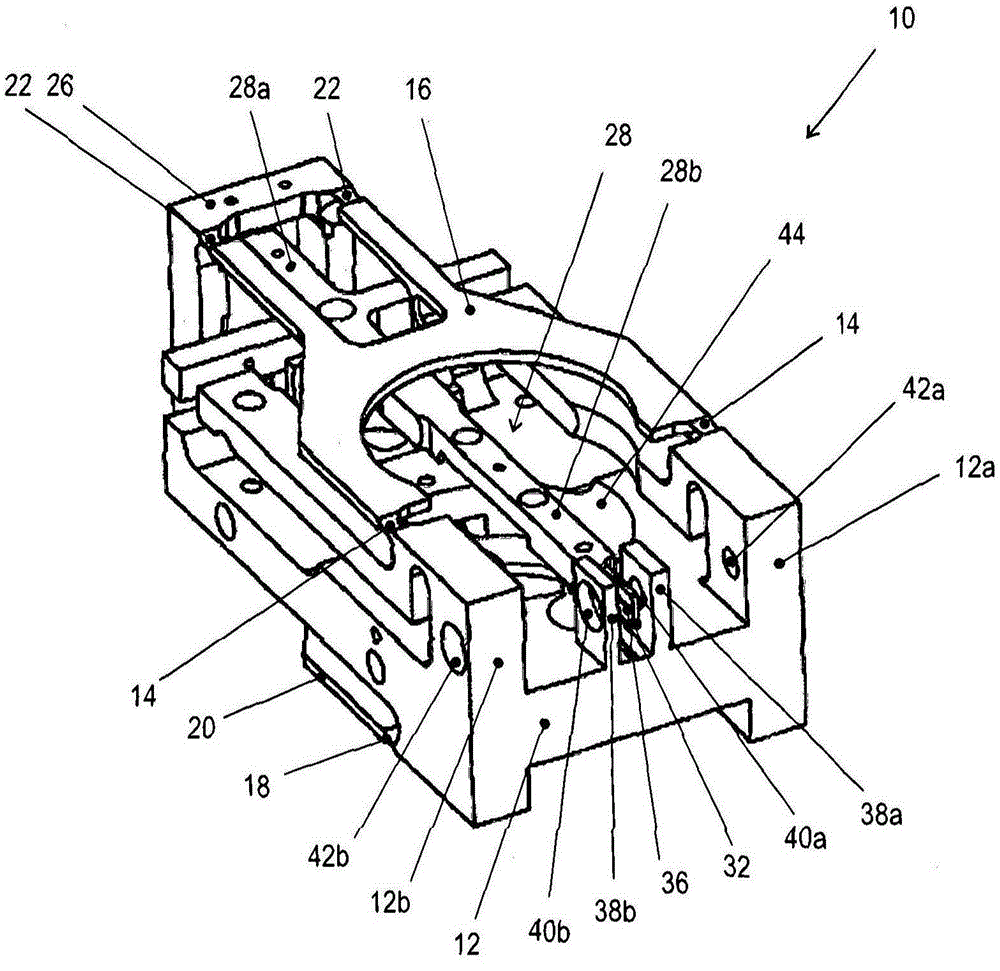

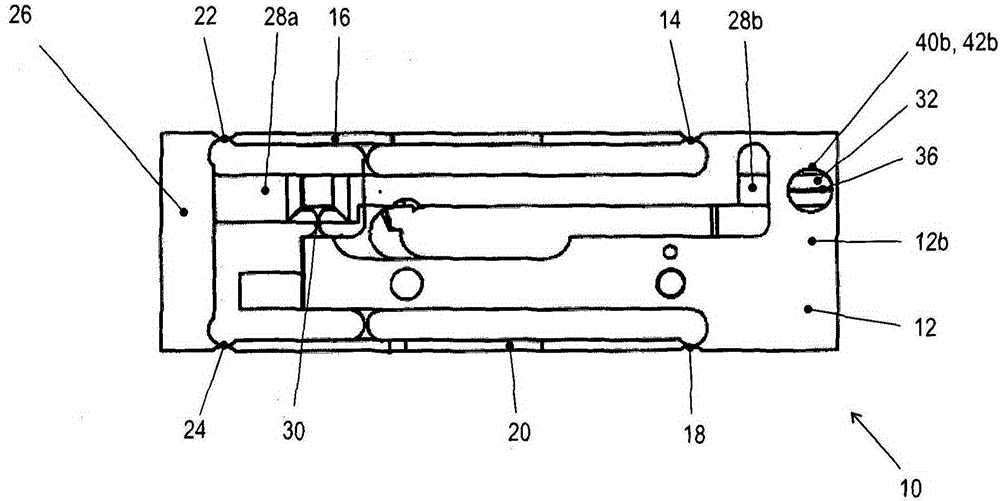

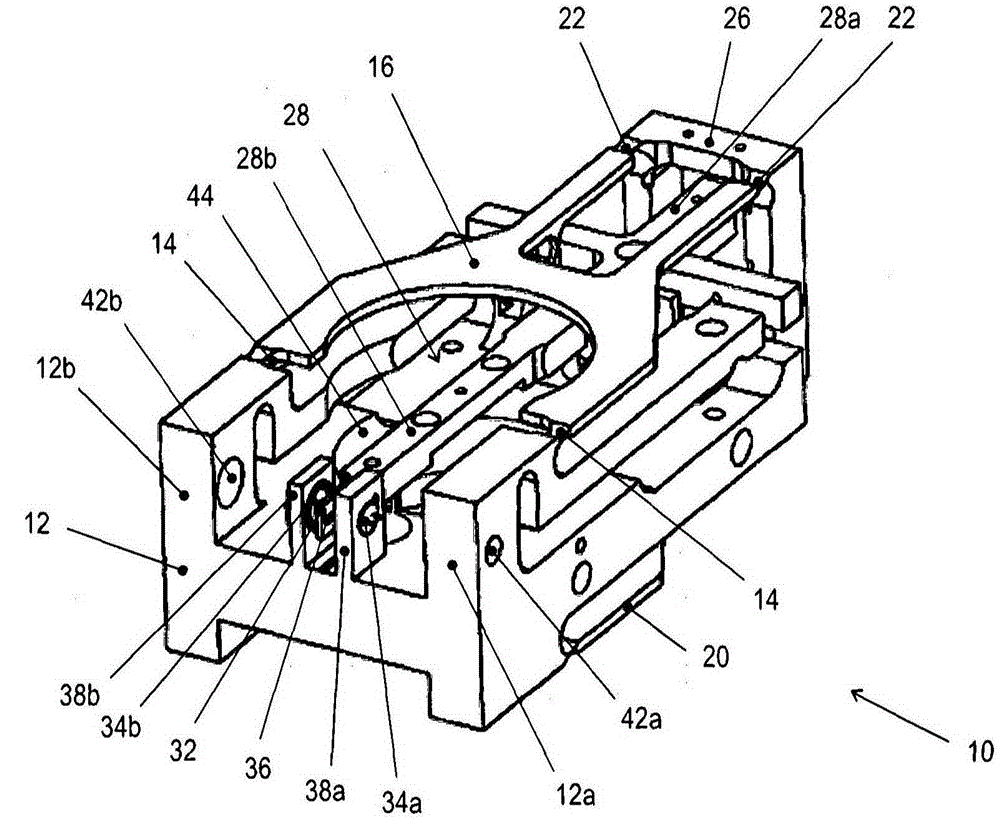

[0022] figure 1 and figure 2 An embodiment of the weighing system 10 according to the invention in the form of a one-piece construction is shown. image 3 The same one-piece weighing system 10 is shown, extended with position sensors. In particular, by adding force compensation, suitable electronics, further expansion of the weighing pan and housing, a weighing device with a wide range of applications is finally constructed. Therefore, as long as no separate emphasis is placed on referring to particular illustrations, the following Figure 1 to Figure 3 Make a common description.

[0023] The weighing system 10 is designed in one piece, that is to say it is manufactured in one piece from a block of material. For this purpose, aluminum blocks are preferably used which are produced as stress-free as possible. Machining is first performed mechanically, in particular by milling and drilling, preferably using a programmable CNC machine tool.

[0024] The weighing system 10 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com