Shoe tree manufacturing process and shoe customizing system

A manufacturing process and technology for shoe lasts, applied in shoe lasts, footwear, applications, etc., can solve problems such as unrealistic, high cost, unfavorable promotion and application, and achieve reduced production costs, low costs, and tight and stable shoe last combinations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

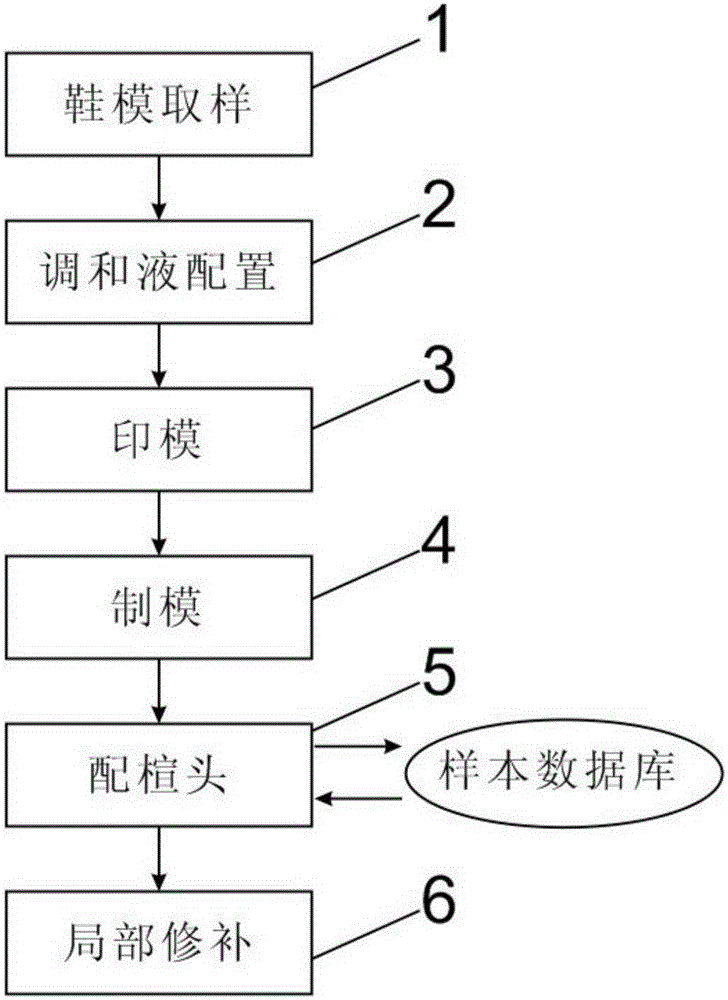

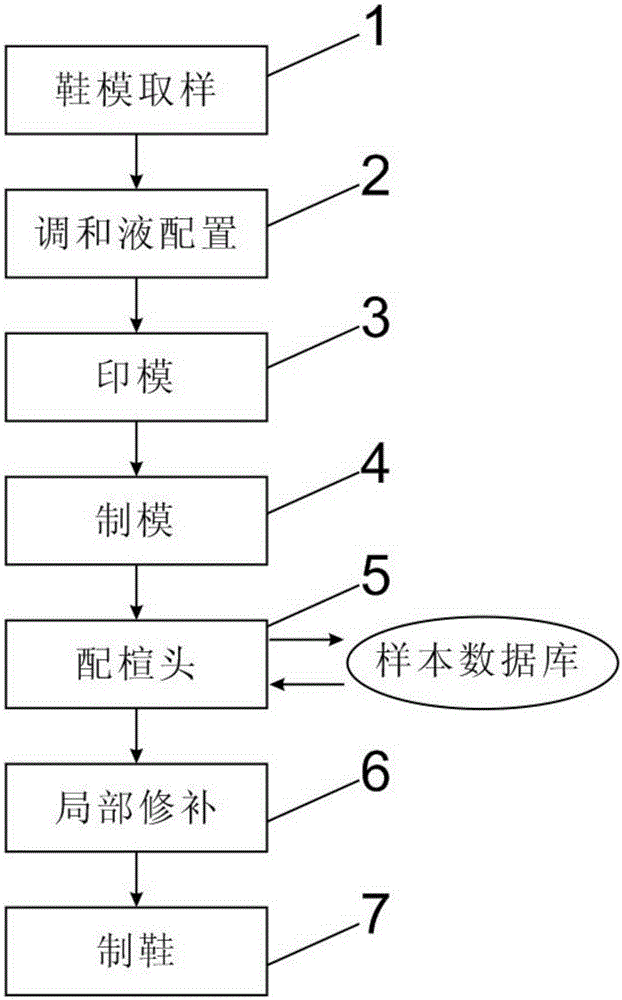

[0050] refer to figure 1 , figure 2 , a manufacturing process of a shoe last, specifically: the actual foot to be tested is used as a standard sample, the foot mold sampling is based on the standing posture, the standard sample should stand naturally, and the weight is evenly distributed on the standard sample, about the same width as the shoulders, Make the foot model more accurate. Then according to the proportion of impression material and 27 ℃ water: 10 grams to 23 ml, accurately weigh; secondly, add the above-mentioned weighed water into the container, and then add the above-mentioned weighed impression material, and use a mixer Stir evenly for 13 seconds, and then obtain a blended solution. Pour the prepared concoction into the container immediately, and then put the standard sample into the container to keep it in a stable state. After 3 minutes of curing time, carefully take out the standard sample; after getting the impression, put it in an absorbent sponge to keep...

Embodiment 2

[0052] refer to figure 1 , figure 2 , a manufacturing process of a shoe last, specifically: the actual foot to be tested is used as a standard sample, the foot mold sampling is based on the standing posture, the standard sample should stand naturally, and the weight is evenly distributed on the standard sample, about the same width as the shoulders, Make the foot model more accurate. Then according to the proportion of impression material and water at 31°C: 10 grams to 23 milliliters are accurately weighed; secondly, add the above-mentioned weighed water into the container, and then add the above-mentioned weighed impression materials, and use a mixer Stir evenly for 25 seconds to obtain a blended solution. Pour the prepared concoction into the container immediately, and then put the standard sample into the container to keep it in a stable state. After 5 minutes of solidification, carefully take out the standard sample; after getting the impression, put it into an absorben...

Embodiment 3

[0054] refer to figure 1 , figure 2 , a manufacturing process of a shoe last, specifically: the actual foot to be tested is used as a standard sample, the foot mold sampling is based on the standing posture, the standard sample should stand naturally, and the weight is evenly distributed on the standard sample, about the same width as the shoulders, Make the foot model more accurate. Then according to the proportion of impression material and water at 23°C: 10 grams to 23 milliliters are accurately weighed; secondly, add the above-mentioned weighed water into the container, and then add the above-mentioned weighed impression materials, and use a mixer Stir evenly for 18 seconds, and then obtain a blended solution. Pour the prepared concoction into the container immediately, and then put the standard sample into the container to keep it in a stable state. After 4 minutes of solidification, carefully take out the standard sample; after getting the impression, put it into an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com