A bundle of tiof 2 low temperature preparation method

A low-temperature, solution technology, applied in chemical instruments and methods, chemical/physical processes, catalysts for physical/chemical processes, etc., can solve problems such as energy consumption and complex process, and achieve good response, good degradation performance, and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

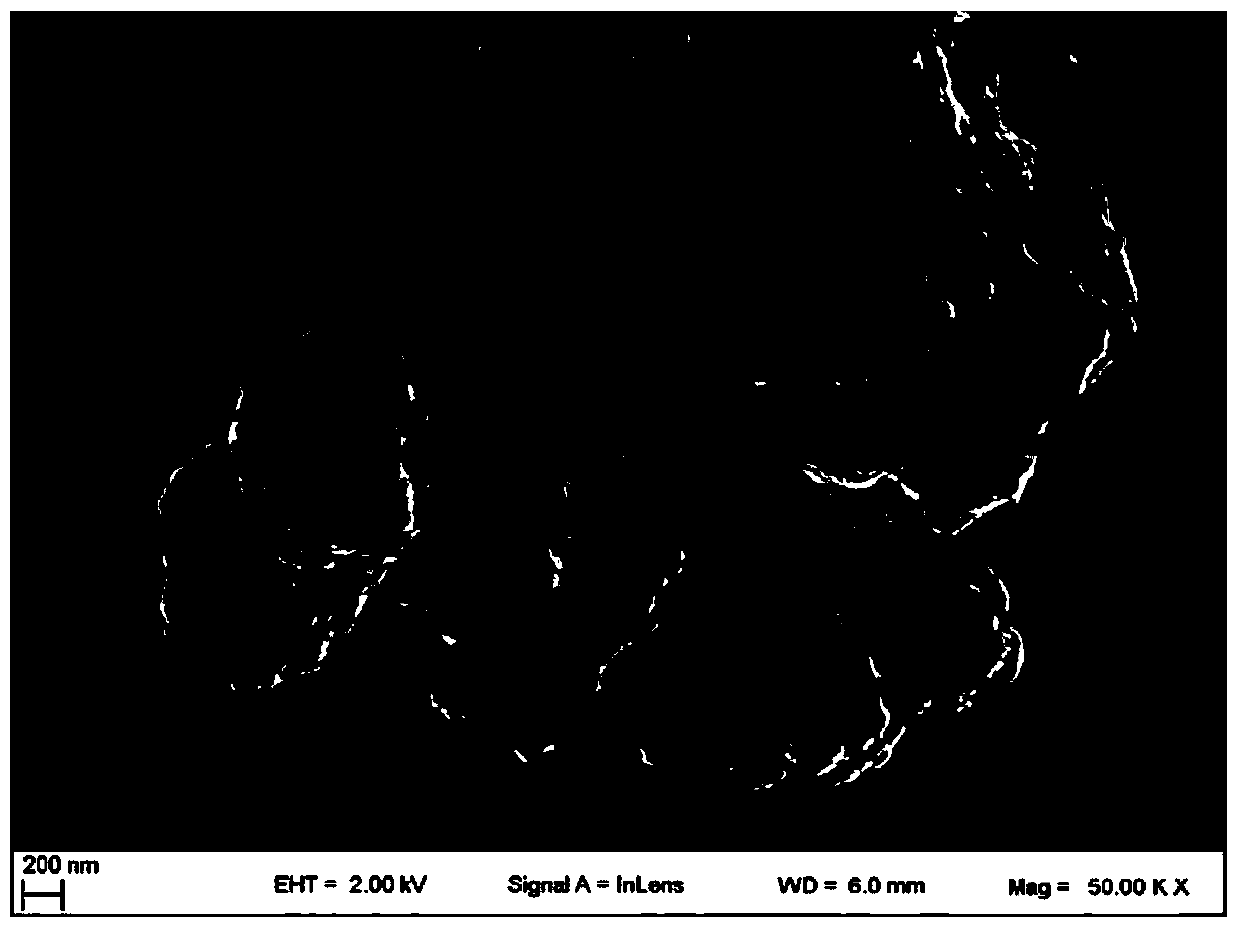

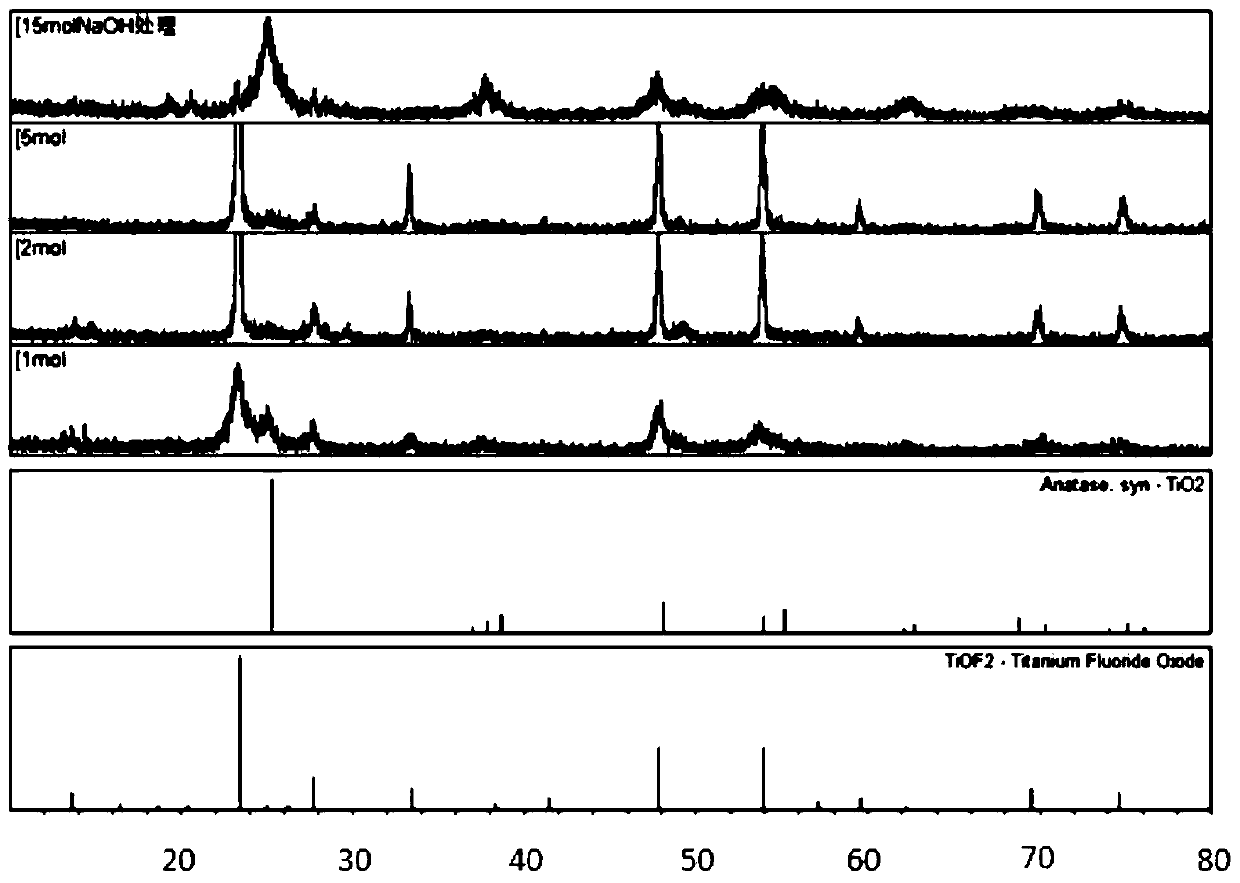

[0018] This embodiment prepares bundled TiOF 2 The method consists of the following steps:

[0019] (1) Measure 30.4mL of absolute ethanol, add it into 35.2mL of butyl titanate according to the volume ratio of butyl titanate to absolute ethanol of 1.15:1, and mix well to obtain A solution;

[0020] (2) Measure 30.4 mL of absolute ethanol and add it to 180 mL of deionized water, and add 20.2 mL of HF at the same time, so that the volume ratio of deionized water, absolute ethanol, and HF is 1:0.169:0.112 to obtain solution B;

[0021] (3) Add solution B to solution A drop by drop, so that the molar ratio of butyl titanate in mixed solution A to deionized water in mixed solution B is 1:100, and the dropping speed is controlled at 3 drops per second, at 60°C , 650r / min constant temperature magnetic stirring for 2 hours to obtain TiOF 2 Gel, aged at room temperature for 2 days;

[0022] (4) The aged TiOF 2 The gel was moved to a blast drying oven at 100°C for constant temperatu...

Embodiment 2

[0025] This embodiment prepares bundled TiOF 2 The method consists of the following steps:

[0026] (1) Measure absolute ethanol, add it to butyl titanate according to the ratio of butyl titanate to absolute ethanol volume ratio of 1:1, and mix well to obtain A solution;

[0027] (2) Take deionized ethanol and HF and add them into deionized water so that the volume ratio of deionized water, dehydrated ethanol and HF is 1:0.1:0.1 to obtain solution B;

[0028] (3) Add solution B to solution A dropwise, so that the molar ratio of butyl titanate in mixed solution A to deionized water in mixed solution B is 1:90, and the dropping speed is controlled at 2 drops per second, at 55°C , 500r / min constant temperature magnetic stirring for 3 hours to obtain TiOF 2 Gel, aged at room temperature for 1 day;

[0029] (4) The aged TiOF 2 The gel was moved to a blast drying oven at 80°C and dried at a constant temperature, washed with distilled water and ethanol three times alternately, dr...

Embodiment 3

[0032] This embodiment prepares bundled TiOF 2 The method consists of the following steps:

[0033] (1) Measure absolute ethanol, add it to butyl titanate according to the ratio of butyl titanate to absolute ethanol volume ratio of 1.2:1, and mix well to obtain A solution;

[0034] (2) Take deionized ethanol and HF and add them into deionized water so that the volume ratio of deionized water, dehydrated ethanol and HF is 1:0.2:0.2 to obtain solution B;

[0035] (3) Add solution A to solution B dropwise, so that the molar ratio of butyl titanate in mixed solution A to deionized water in mixed solution B is 1:105, and the dropping speed is controlled at 3 drops per second, at 58°C , 800r / min constant temperature magnetic stirring for 1 hour to obtain TiOF 2 Gel, aged at room temperature for 3 days;

[0036] (4) The aged TiOF 2 The gel was moved to a blast drying oven at 90°C and dried at a constant temperature, washed alternately with distilled water and ethanol three times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com