Grinding and polishing device for automatic grinding and polishing machine

A polishing device and polishing machine technology, used in grinding devices, grinding machine tools, preparation of samples for testing, etc., can solve the problems of low polishing efficiency of hard samples, uneven polishing surfaces of samples, and large differences in size, etc., to avoid The effect of uneven polishing surface, improving efficiency, ensuring grinding accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

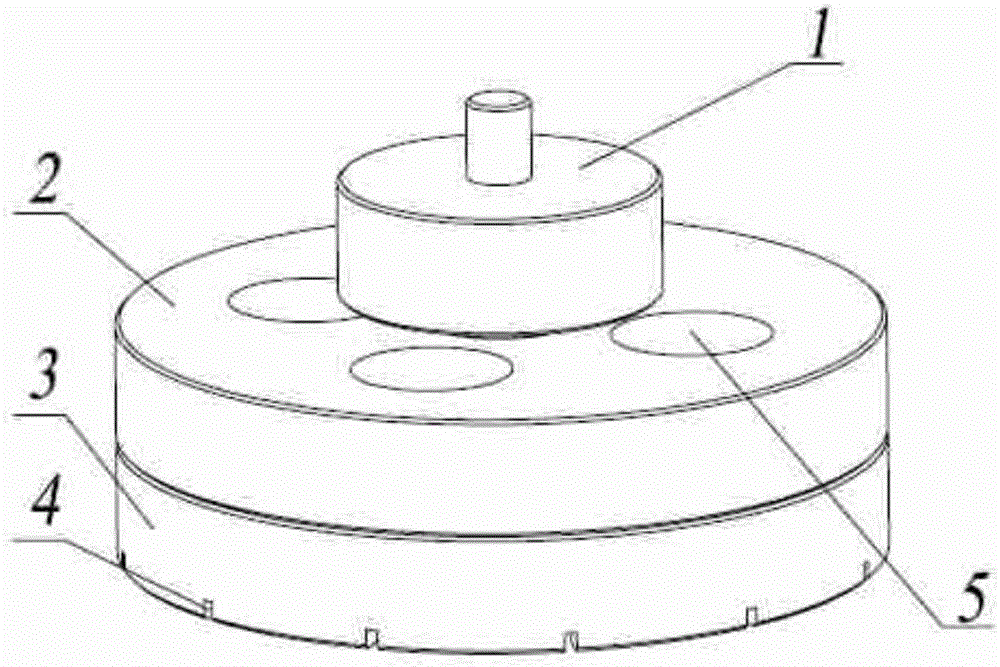

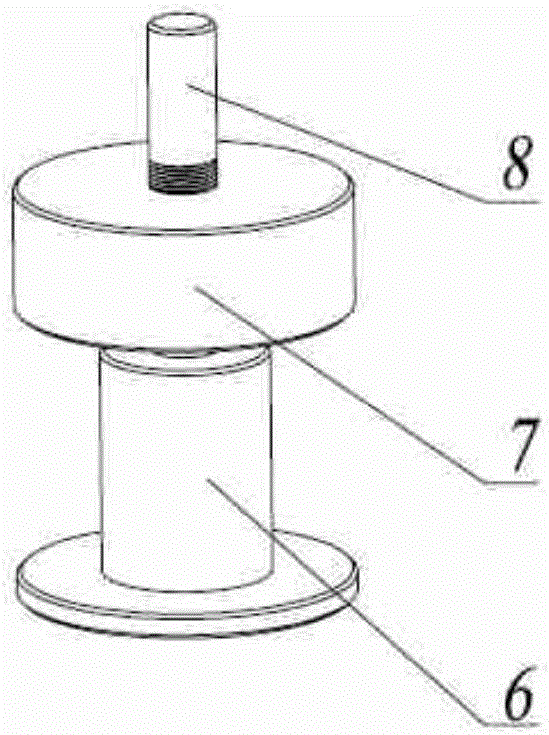

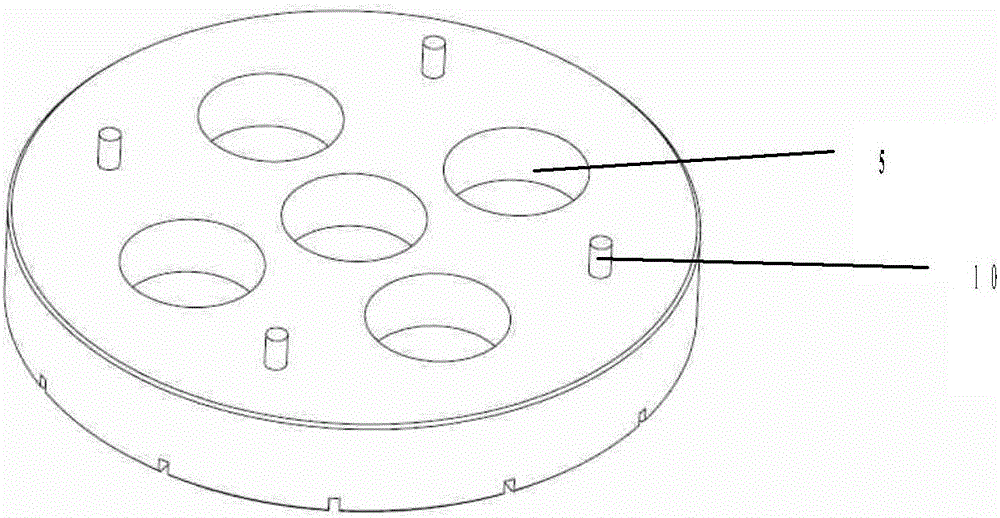

[0027] The invention proposes a grinding and polishing device for an automatic grinding and polishing machine, such as figure 1 As shown, it includes a sample loading tray 1 and a repairing ring, and the repairing ring is a separate structure, including an upper layer repairing ring 2 (such as Figure 4 Shown) and the lower repair disk ring 3 (such as image 3 As shown), wherein, the bottom of the upper sample loading tray is provided with 4 limit grooves 9, the upper surface of the lower sample loading tray is provided with 4 fixed columns 10 corresponding to the limit grooves of the upper sample loading tray, and the upper layer of the sample loading tray is repaired. The ring 2 and the lower repairing ring 3 are fixed through the mutual cooperation of the limiting groove and the fixing post. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com