Dust remover of bamboo piece longitudinal cutting machine

A technology of dust removal device and slicer, which is applied in mechanical equipment, sugarcane machining, bark area/debris/dust/waste removal, etc. problems, to achieve the effect of ensuring the degree of cleanliness, the structure is simple, and the degree of automatic cleaning is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

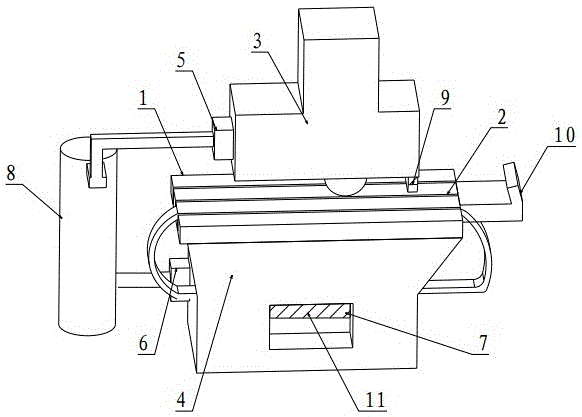

[0015] Such as figure 1 As shown, the dust removal device of the bamboo chip vertical section slicer includes a dust removal cover 3 arranged on the top of the work surface 1, and a horn-shaped collector 4 arranged on the conveyor belt 2 below the work surface, and at least one side of the dust removal cover 3 is provided. There is a first dust removal device 5, and a second dust removal device 6 is also provided on one side of the horn-shaped collector 4, and both the first dust removal device 5 and the second dust removal device 6 are automatic dust suction devices. The dedusting device of the present invention is provided with a dedusting cover 3 respectively above its work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com