Full-automatic inner film bag bagging and joint-cutting dual-purpose integrated machine for plastic woven bags

A plastic woven bag, fully automatic technology, applied in the direction of container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problems of low production efficiency, waste of labor, large floor space, etc., to achieve stable quality and save manpower , the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

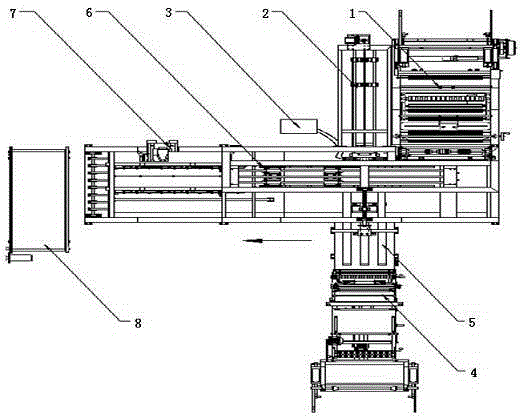

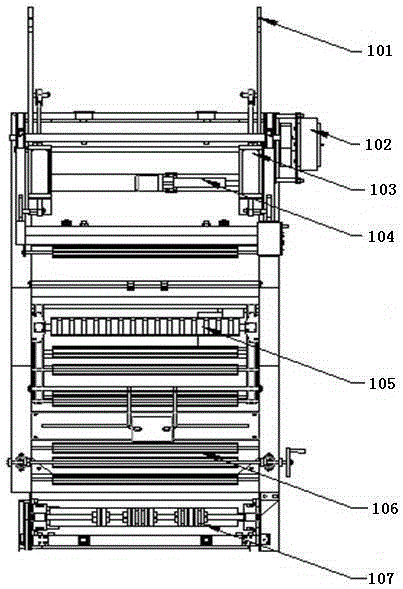

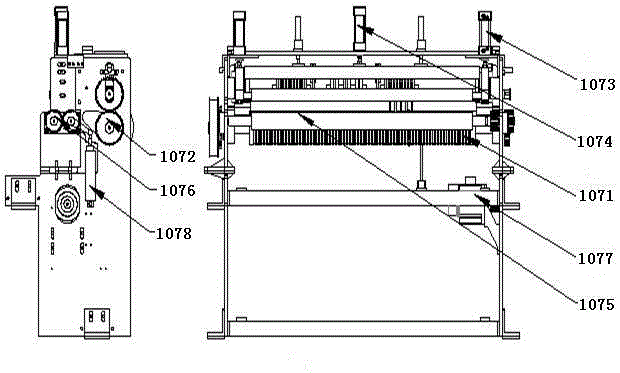

[0021] Example: such as figure 1 As shown, a plastic woven bag full-automatic plastic woven bag inner membrane bag cutting and sewing dual-purpose integrated machine includes a bottom sewing and conveying mechanism 7, a finished bag output mechanism 8 is arranged at one end of the bottom sewing and conveying mechanism 7, and a finished bag output mechanism 8 is arranged at the bottom sewing and conveying mechanism 7 The other end of the outer bag mobile pickpocket mechanism 6 is connected, and one side of the outer bag mobile pickpocket mechanism 6 is provided with an inner film bag making machine 4, and a cover is also arranged between the inner film bag making machine 4 and the outer bag mobile pickpocket mechanism 6. The bag intermediate mechanism 5, the other side of the outer bag mobile pickpocket mechanism 6 is provided with an outer bag unwinding station 1 and an inner film bag loosening mechanism 2, and an outer bag opening mechanism 3 is also connected to the inner fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com