A kind of lightweight composite lattice sandwich panel and its preparation method

A technology of composite lattice and sandwich panels, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of insufficient shear and tensile bearing capacity, undetectable connection quality, and difficulty in preparing large panels. , to achieve the effects of easy quality control, low cost and short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

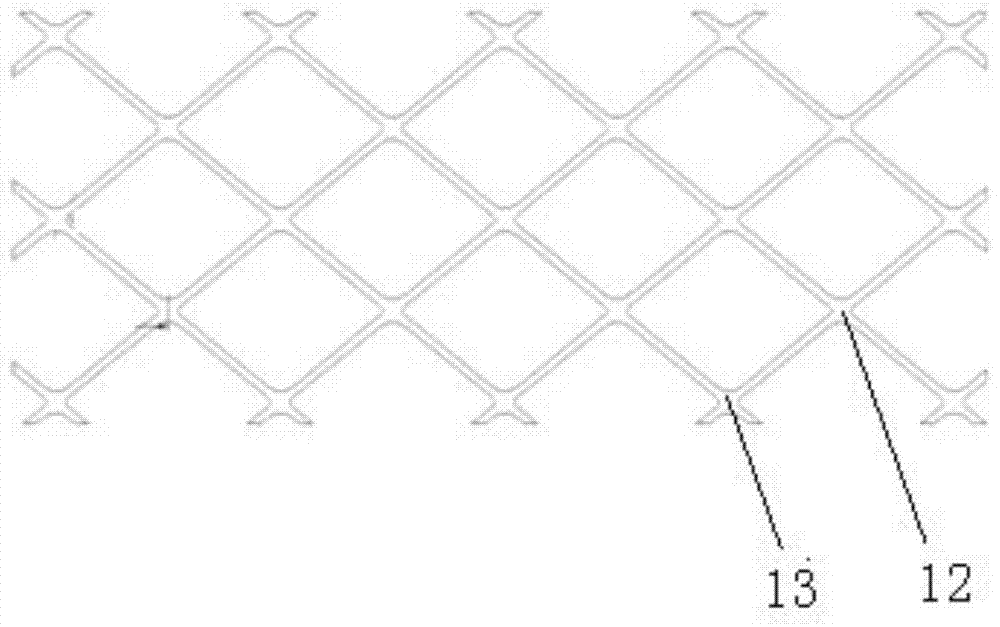

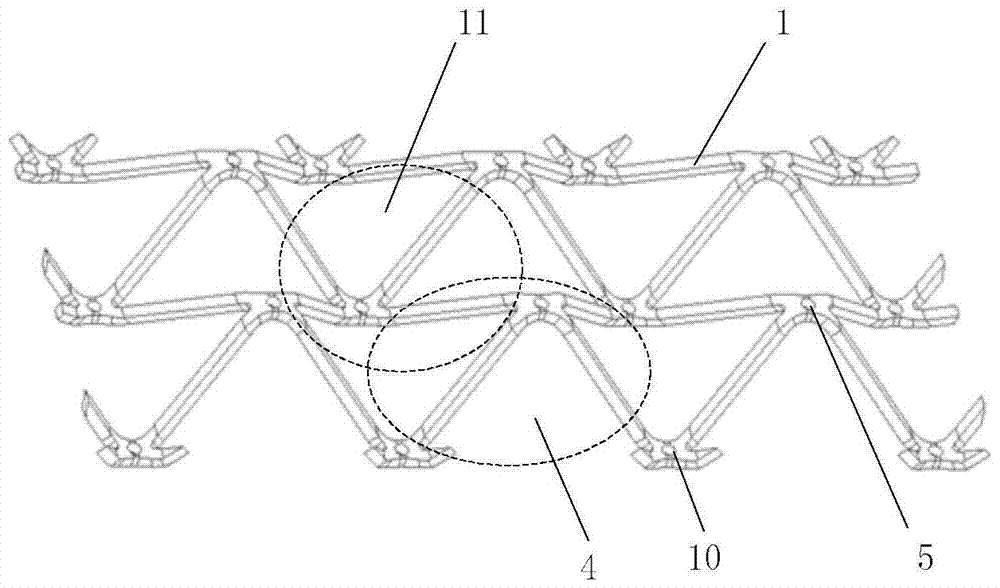

[0045] The structure of a lightweight composite lattice sandwich panel of the present invention is as follows Figure 2-6 As shown, it includes a pyramidal lattice core 1, an upper panel 2 and a lower panel 3; the pyramidal lattice core 1 is made up of a plurality of pyramidal lattice structure unit cells-4; the pyramidal lattice The structural unit cell-4 is a pyramid-shaped integral piece composed of four rods; in the four pyramid-shaped lattice structural unit cells-4 adjacent to each other, the intersecting four rods are combined to form a pyramid-shaped Lattice structure unit cell one 4 is a pyramid-shaped lattice structure unit cell two 11 in opposite directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com