Rail grasping device of catenary vehicle ladder

A rail catcher and catenary technology, which is applied in the field of catenary ladder rail grabbers, can solve the problems of inconvenient use, poor stability, and low safety performance, and achieve the effects of easy portability, stability assurance, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following examples are given to describe the embodiments in conjunction with the accompanying drawings.

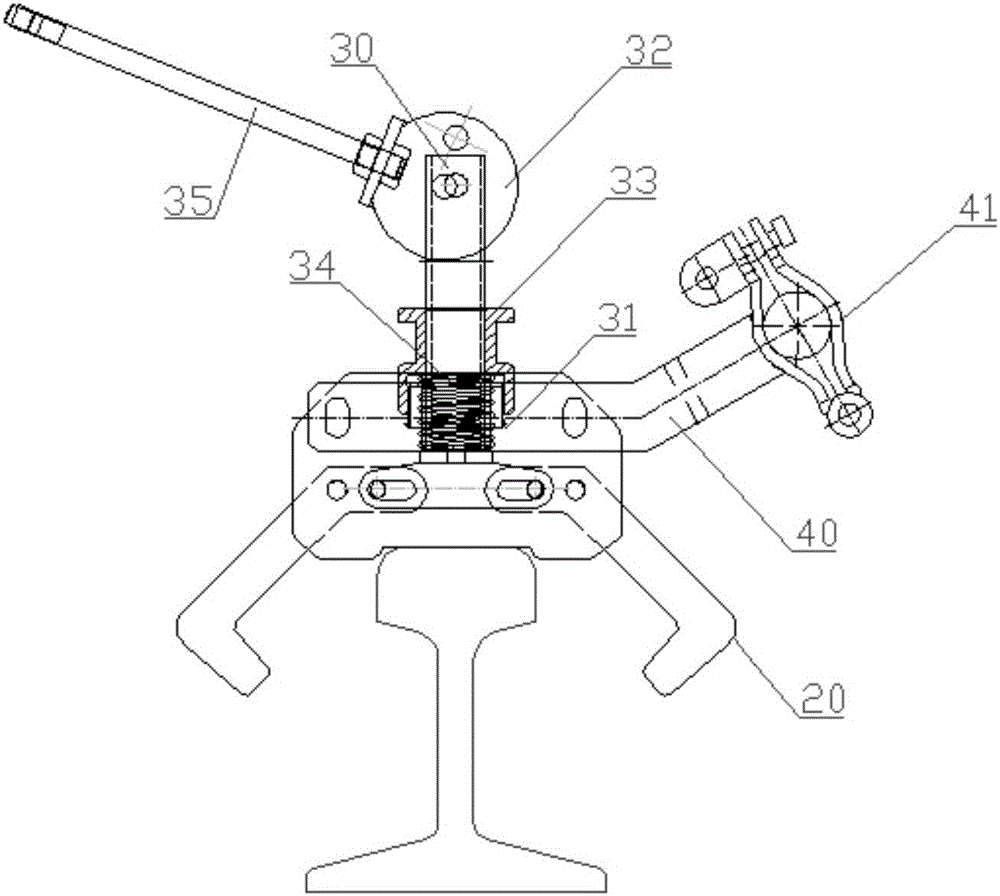

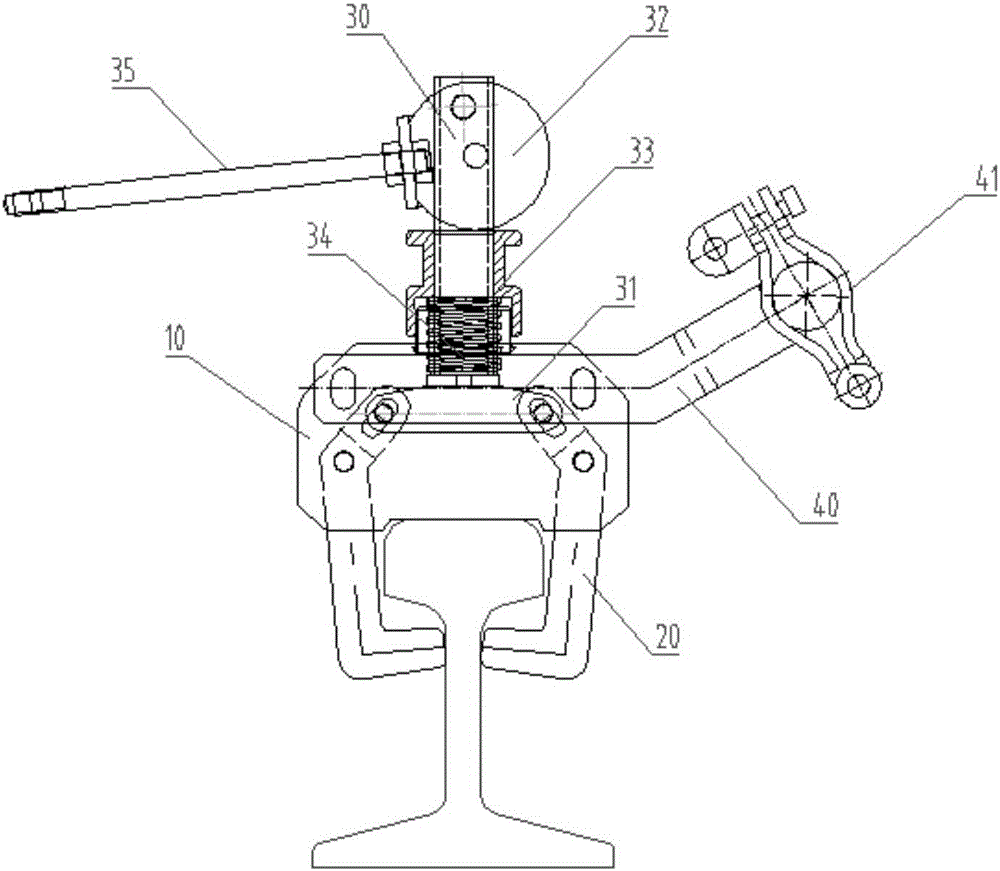

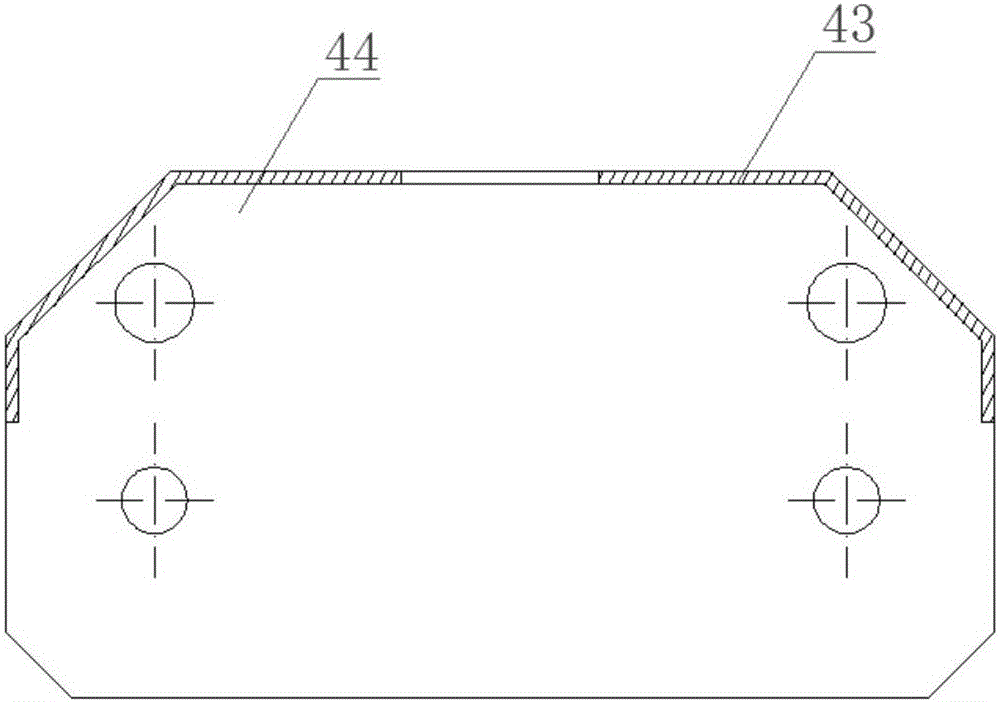

[0018] see figure 1 shown, combined with Figure 2 to Figure 4 As shown, the present invention provides a catenary ladder rail grab, which includes a base 10 and a catch 20 hingedly mounted on the base 10, wherein the base 10 of the present invention includes two parallel The side plates 11 arranged at intervals and the top plate 12 installed between the two sides, the catch 20 is installed between the two side plates 11 and can rotate around the hinge with the side plates 11, on the top plate 12 of the present invention A pull rod 30 is movable, and the bottom of the pull rod 30 is provided with a push plate 31 that can act on the grip 20, and a cam 32 is installed on the top of the pull rod 30, and the cam 32 can rotate relative to the pull r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com