Self-elevating type lifting platform installing technology

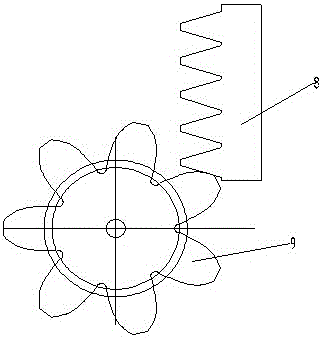

A lifting platform and installation technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve problems such as poor control of the angle between the tooth shape of the climbing gear and the vertical direction, unreasonable structural settings, and lack of locking devices. , to achieve the effect of convenient structure operation, stable structure and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention discloses a self-elevating lifting platform installation process, the process steps are as follows:

[0028] (1) Site layout: close up the site, level the surface, and clean up the sundries;

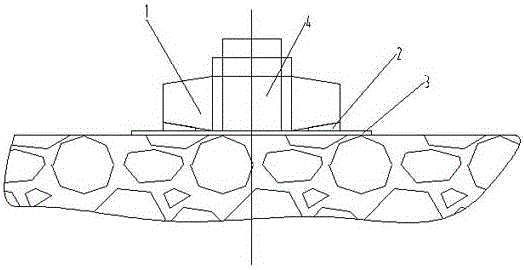

[0029] (2) Positioning of spud shoe 1: if figure 1 As shown, draw the installation position lines of the four spud shoes 1 on the closed site, place the spud shoes 1 in place, adjust the level of the spud shoes 1, and ensure the verticality of the spud shoe cylinder 4; check the openings between the four spud shoes 1 The file size and diagonal size, if out of tolerance, need to be adjusted, and then according to the requirements of the drawing, the upper margin of the spud shoe 1 should be trimmed in place; a steel plate 3 should be placed between the spud shoe and the closing site, and wooden wedges should be used for the gap 2 pad solid, wooden wedge 2 internal ribs aligned;

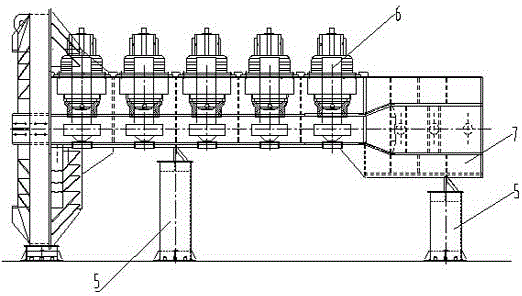

[0030] (3) Hull closure: Draw the four-section installation position line at the trunk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com