Aircraft empennage regulation mechanism with pitching and yawing completely decoupled

A completely decoupling and adjusting mechanism technology, applied in the field of aircraft, can solve the problems of slow response speed, low precision, and increasing the weight of the aircraft tail, so as to achieve the effect of reducing weight and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

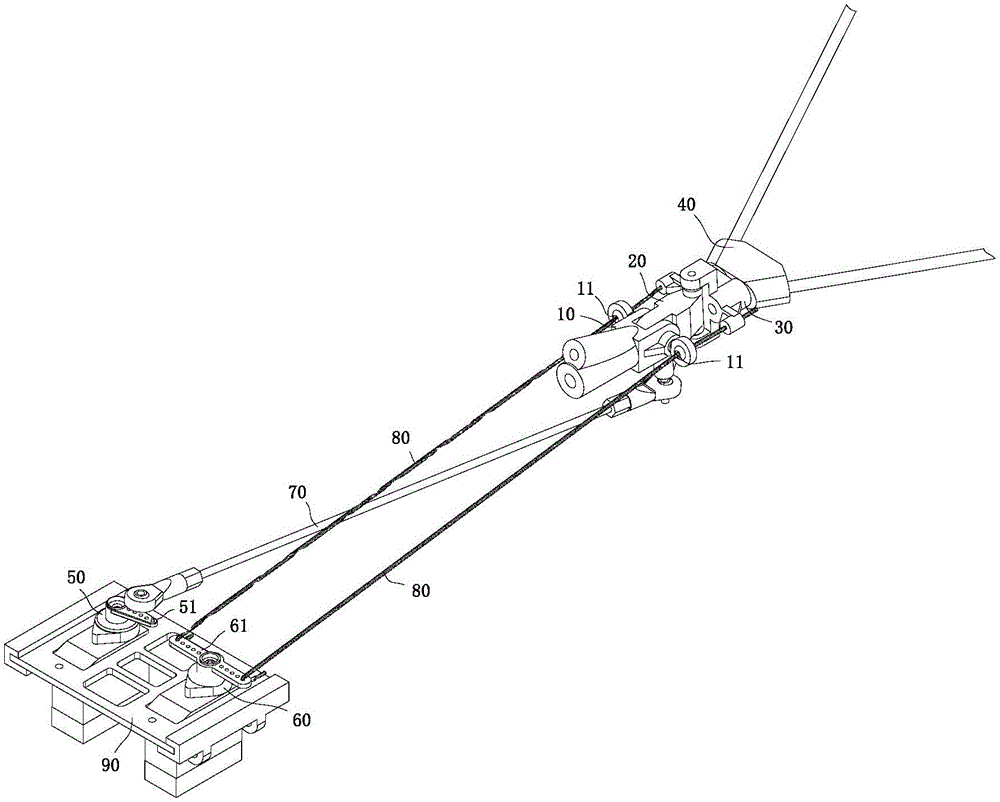

[0020] refer to figure 1 , an empennage adjustment mechanism for an aircraft that is completely decoupled from pitch and yaw in the present invention, comprising an empennage fixing part 10, an empennage pitching part 20 and an empennage yaw part 30 arranged on the tail of the aircraft in sequence, and the empennage fixing part 10 is fixedly installed At the rear of the aircraft, the empennage fixing part 10 and the empennage pitching part 20 are hinged by a pitching shaft, and the axis of the pitching shaft is horizontal, so that the empennage pitching part 20 can swing up and down relative to the empennage fixing part 10 around the axis of the pitching shaft , the empennage pitching part 20 and the empennage yaw part 30 are hinged by a yaw shaft, and the axis of the yaw shaft is vertical, so that the empennage yaw part 30 can rotate around the axis of the yaw shaft relative to the empennage pitching part 20 Swing left and right, the empennage module 40 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com