Control method for aircraft carbon-ceramic wheel braking system with adjustable maximum braking pressure

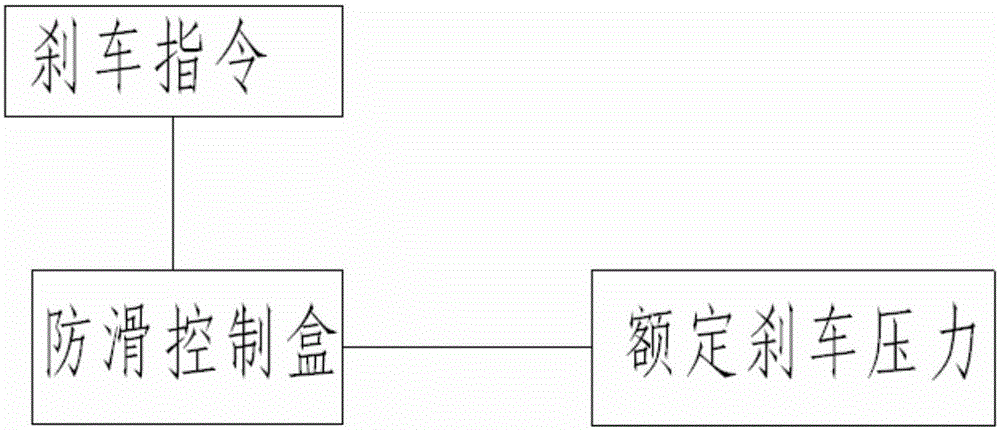

A braking system and a carbon-ceramic machine wheel technology are applied in the field of aircraft carbon-ceramic machine wheel braking systems, and can solve the problem of not using aircraft drag umbrella signals to control the aircraft carbon-ceramic machine wheel braking system. Technical report, no aircraft carbon-ceramic machine wheel braking system control technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

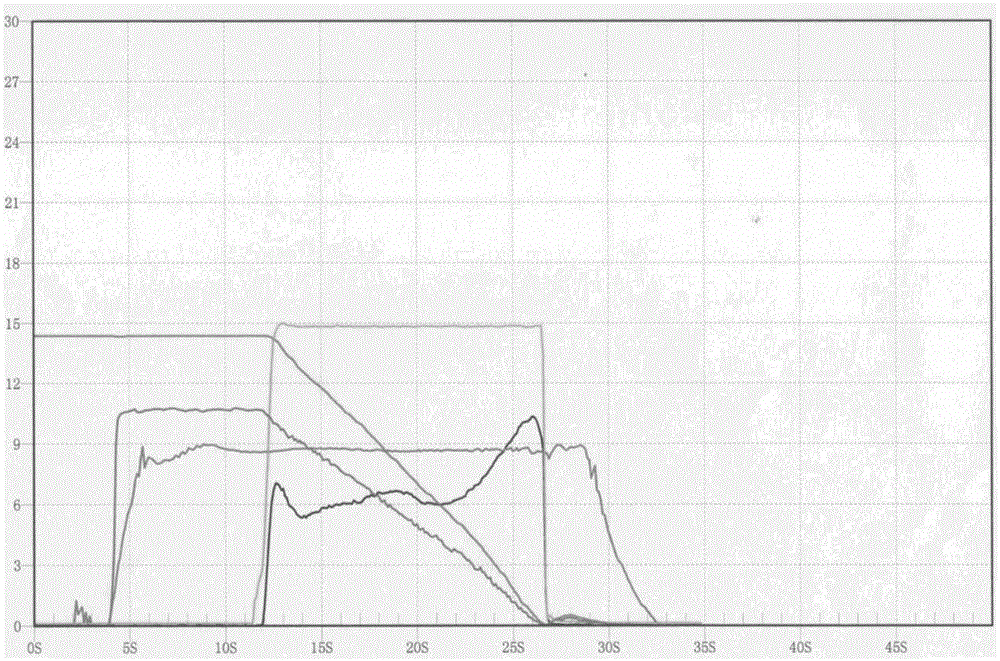

Embodiment 1

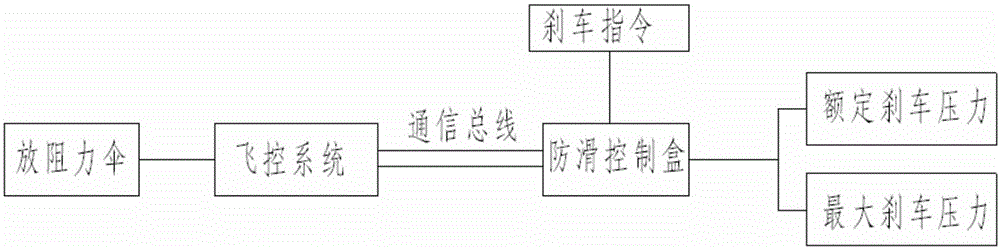

[0065] This embodiment is a method for controlling the brake system of a certain type of carbon ceramic machine wheel brake through a drag parachute. The specific process is:

[0066] Step 1, the anti-skid control box receives the control command of the drag parachute

[0067] When the aircraft lands, a drag parachute signal is sent to the anti-skid control box.

[0068] There are two ways to decelerate the plane when it lands, one is to put the drag parachute, and the other is not to put the drag parachute.

[0069] If the aircraft lands without a drag parachute, the anti-skid control box of the carbon-ceramic wheel brake system receives the control command as "0"; if the aircraft lands with a drag parachute, the anti-skid control box of the carbon-ceramic wheel brake system receives the control command to "1".

[0070] The drag parachute signal sent when the aircraft lands is expressed by formula (1):

[0071]

[0072] In this embodiment, the drag parachute is released...

Embodiment 2

[0122] This embodiment is a method for controlling the brake system of a certain type of carbon ceramic machine wheel brake under the condition that the drag parachute is not released, that is, the signal of releasing the drag parachute is "0". The specific process is:

[0123] Step 1, control logic of carbon ceramic wheel brake system

[0124] When the plane lands, turn on the anti-skid switch, the carbon ceramic wheel brake system works, the drag parachute signal sent when the plane lands and the control command received by the carbon ceramic wheel brake system. The control logic is determined by the formula (1):

[0125]

[0126] When the plane lands without a drag parachute, the brake control box of the carbon-ceramic wheel brake system receives a control command of "0"; when the plane lands with a drag parachute, the brake control box of the carbon-ceramic wheel brake system receives a control command of "0". 1".

[0127] In this embodiment, the drag parachute is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com