An automatic sand washing device

An automatic flushing and automatic technology, applied in the direction of dehydration/demulsification adjustment/control, etc., can solve the problems of wasting crude oil resources, polluting the environment, affecting the normal operation of electric desalination equipment, etc., and achieve the effect of reducing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

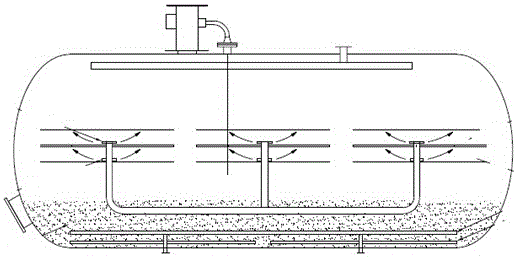

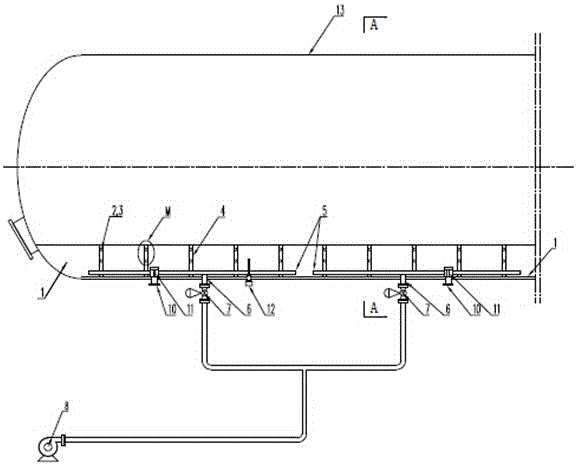

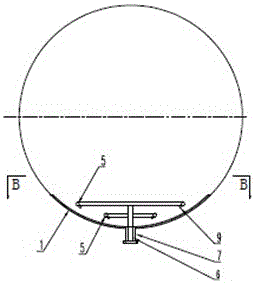

[0026] Such as figure 2 As shown, on the bottom surface of the electric desalination tank 13 , including the bottom surface inside the two heads, a layer of automatic desanding board 1 is compounded. The material of the automatic desanding board 1 is polytetrafluoroethylene sheet, or is sprayed polytetrafluoroethylene. The arc length of polytetrafluoroethylene sheet or sprayed polytetrafluoroethylene coating is about 1 / 4 of the circumference of the electric desalination tank. The thickness of the PTFE sheet or sprayed PTFE coating is determined according to the degree of wear on the surface of the automatic sand removal plate by the deposited sediment and mechanical impurities, and the design service life. After the surface of the PTFE sheet is treated, it can be pasted on the bottom surface of the electric desalination tank. can also be as Image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com