Gate pier prestress anchor cable sleeve installation device and construction method thereof

A prestressed anchor cable and installation device technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of anchor cable pre-embedded pipe 16 difficult to locate, design position deviation, material waste, etc., to avoid structural defects, Stabilize positioning and reduce the effect of rework loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

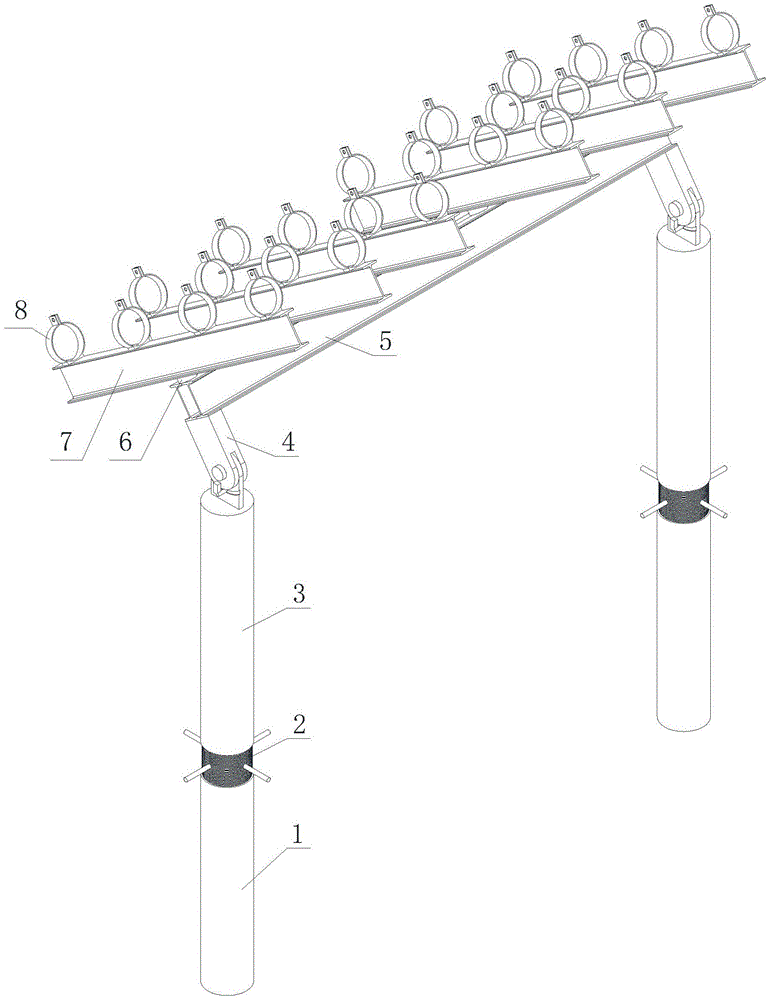

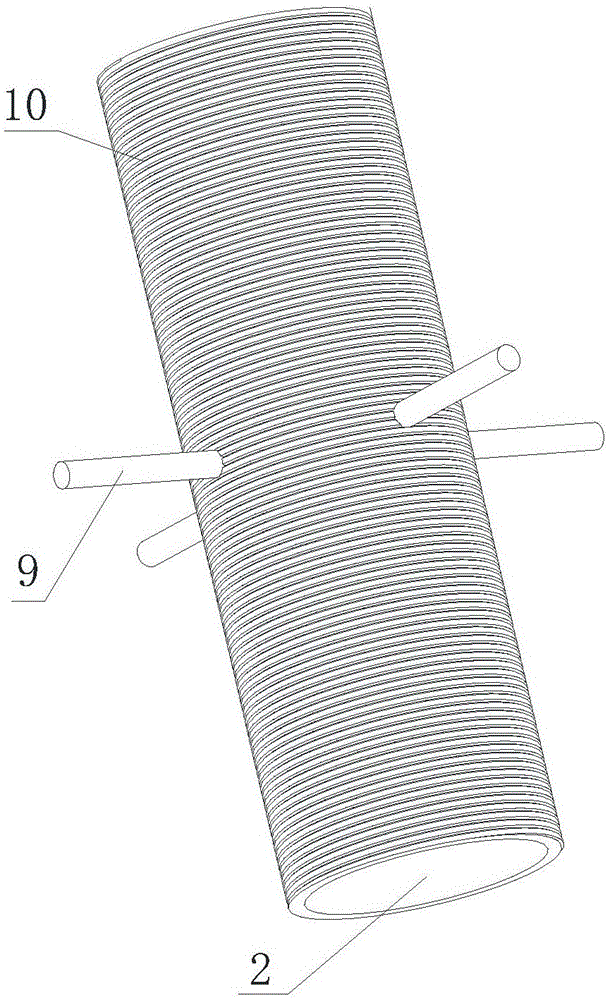

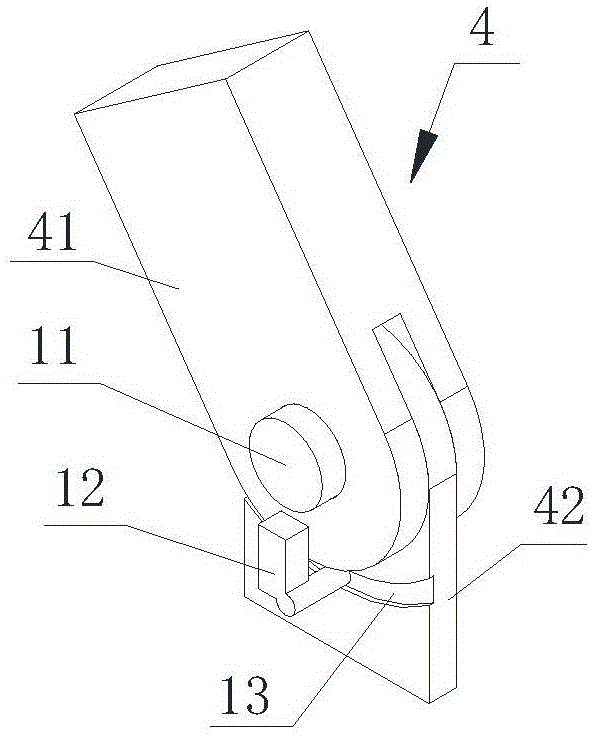

[0033] Such as figure 1 As shown, a kind of gate pier prestressed anchor cable casing installation device described in the present invention comprises support pipe 3 and embedded steel pipe 1 respectively installed on the two ends of beam 5, and the two ends of beam 5 are respectively connected by hinge 4 and The upper end of the support pipe 3 is connected, the upper end of the embedded steel pipe 1 is connected to the lower end of the support pipe 3 through the connecting pipe 2, and several vertical beams 7 are arranged on the cross beam 5, and several hoops 8 are installed on the vertical beam 7 . This technical solution installs the anchor cable pre-embedded pipe by using the collar 8, which can quickly, accurately and stably locate the anchor cable pre-embedded pipe, reduce the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com