Steel frame integrated member for concrete core tube structures and assembly method thereof

A technology of core tube and concrete, which is applied to building components, building structures, earthquake resistance, etc., can solve the problems of structural lateral stiffness, ductility, and energy dissipation capacity reduction, increase construction difficulty and cost, and unsuitable guarantee of welding quality, etc., to achieve The effect of full hysteretic curve, high bearing capacity and high initial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

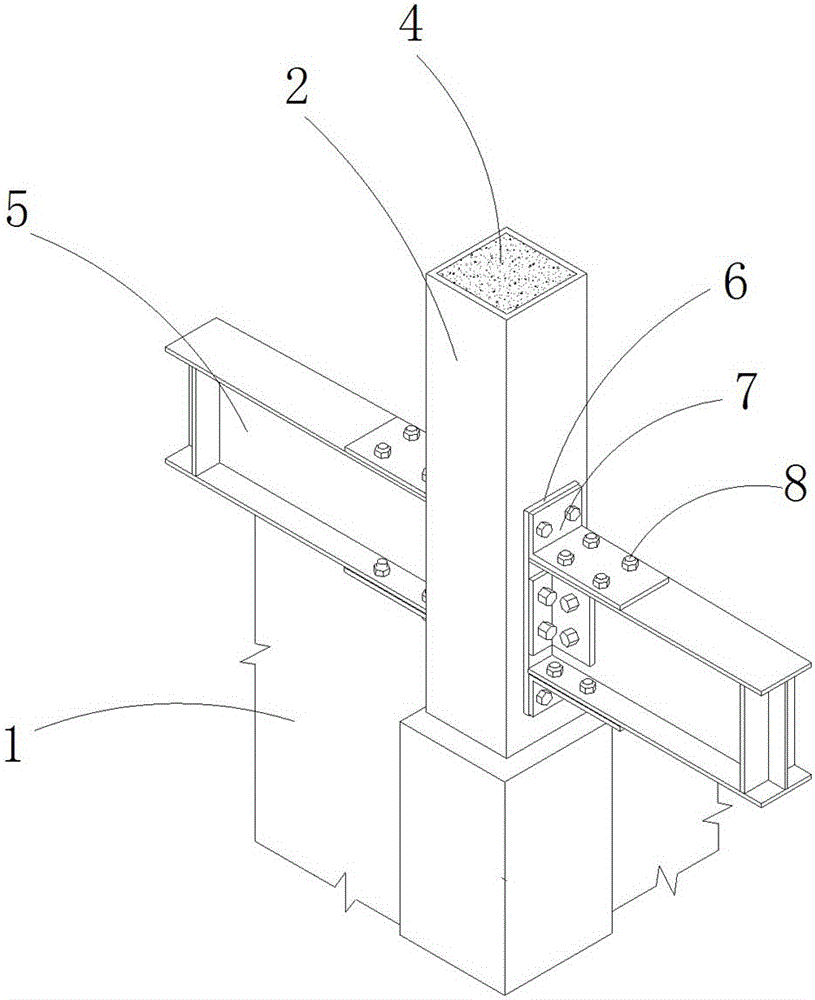

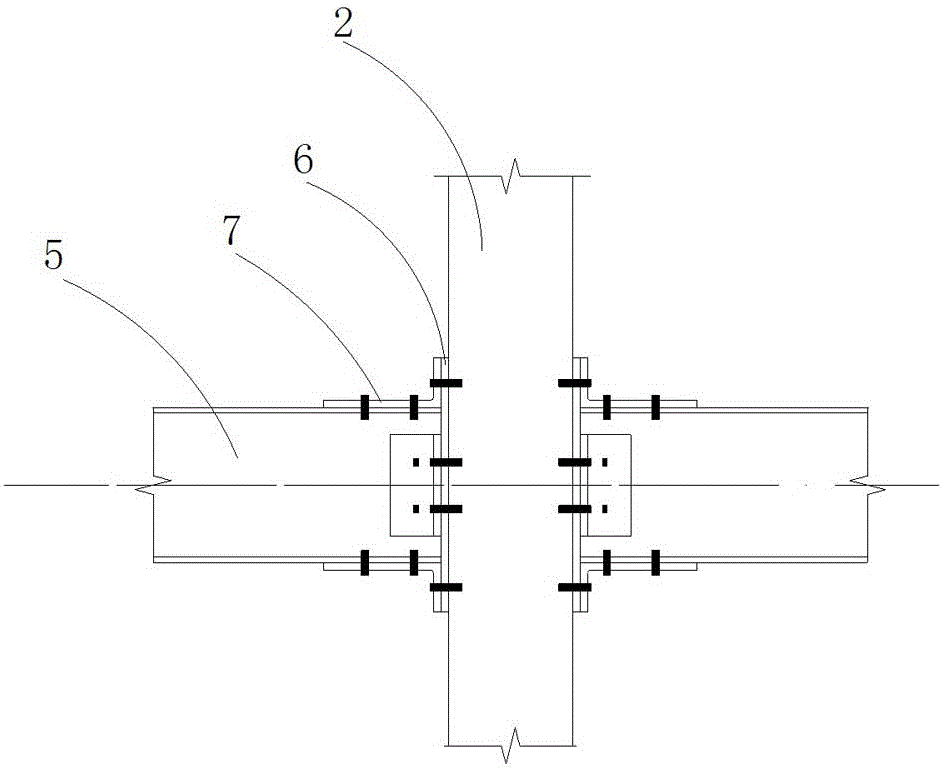

[0030] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a steel frame integrated component for a concrete core tube structure includes a core tube 1, a steel column assembly and a steel beam assembly, the bottom of the steel column assembly is fixed to the core tube 1, and the steel Both sides of the upper end of the column assembly are respectively provided with steel beam assemblies fastened to the steel column assembly;

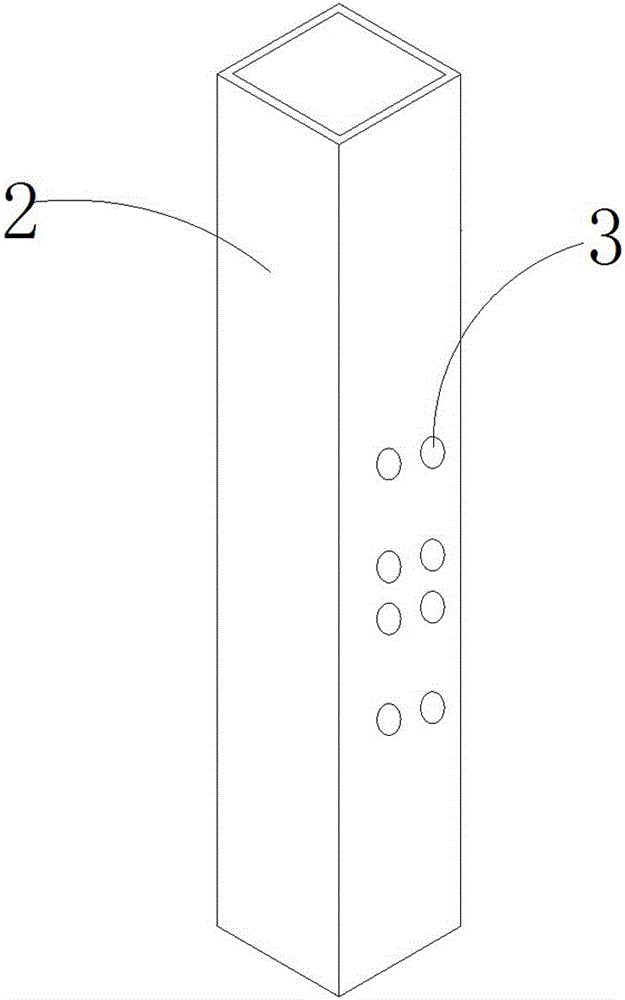

[0031] The steel column assembly includes a steel column 2, the outer wall of the steel column 1 is provided with uniformly distributed fixing holes 3, and the steel column 2 is provided with concrete 4;

[0032] The steel beam assembly includes a steel beam 5, and an overhanging end plate 6 is arranged between the steel beam 5 and the steel column 2, and the steel beam 5 and the steel column 2 are vertically distributed, and the steel beam 5 It is fastened with the steel column 2 through the fixing hole 3, the upper part of the steel beam 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com