A tuned viscous mass damper

A mass damping and viscous technology, applied to building components, shockproof, etc., can solve the problems of low energy consumption efficiency, large tuning quality, etc., and achieve the effects of low manufacturing cost, simple and compact structure, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

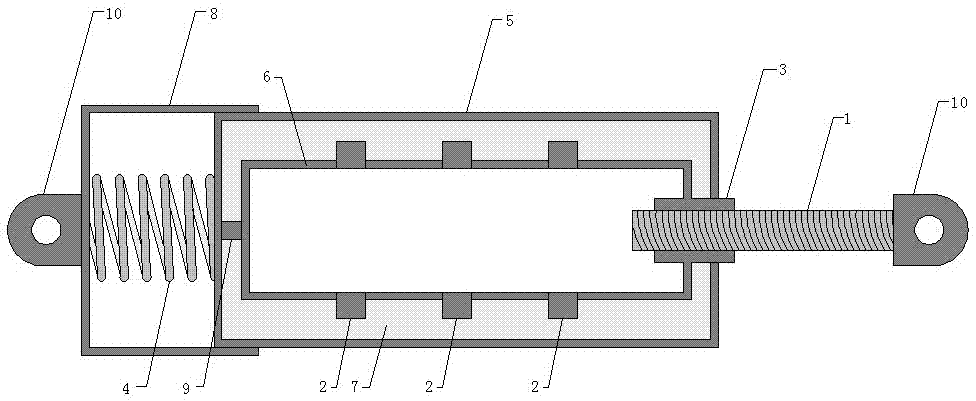

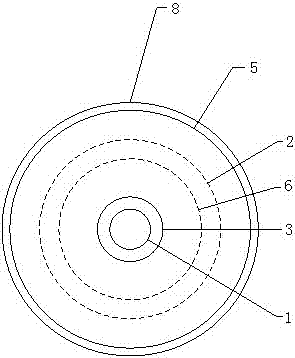

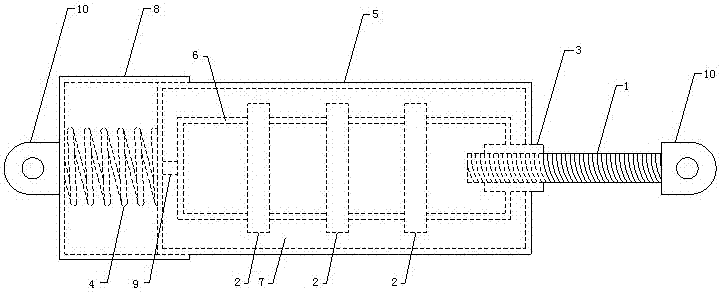

[0018] Example 1: Such as Figure 1~4 As shown, the tuned viscous mass damping device includes the rotating mass 2, the ball nut 3 and the inner cylinder 6 as a whole by welding. The ball screw 1 passes through the right end of the ball nut 3 and the inner cylinder 6 in turn, and is clamped with the ball nut through the thread Together; the right end of the outer cylinder 5 and the ball nut 3 are connected by a groove and sealed well, and the two are not connected as a whole by welding; the left end of the outer cylinder 5 and the left end of the inner cylinder 6 are connected by a ball bearing 9; 5 The left end is connected with the tuning spring 4, so that the damper can play the role of a tuning mass damper; the tuning spring 4 is covered with a tuning spring protection tube 8; the right end of the tuning spring protection tube 8 is attached to the left end of the outer tube 5 wall, both Relative misalignment can occur.

[0019] In the damping device, the rotating mass consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com