A kind of downhole washable well water injection intubation sealing device

A sealing device and well flushing technology, applied in the directions of sealing/isolation, wellbore/well components, cleaning appliances, etc., can solve the problem that the concentric double-pipe sub-injection sealing mechanism cannot perform self-cleaning, etc., to solve the problem of easy scaling and Falling matter deposition, efficient development effect, effect of improving success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

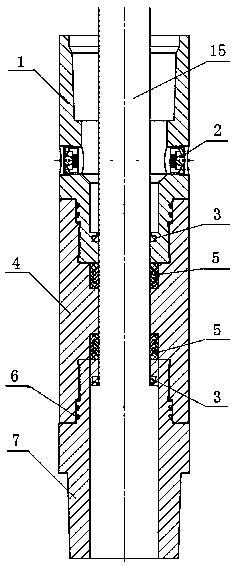

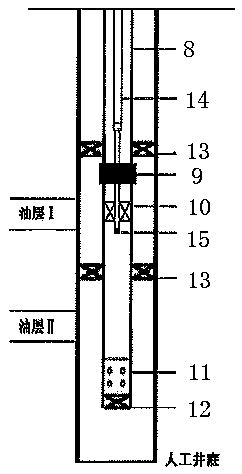

[0016] This embodiment provides a kind of downhole washable well water injection insertion pipe sealing device, such as figure 1 As shown, it includes a tubular main body joint 1, a sheath 4 and a lower joint 7 connected sequentially from top to bottom. The inner diameters of the tubular sheath 4 and the lower joint 7 are equal, and the tubular main body joint 1 The inner diameter of the body is gradually changing, gradually increasing from the bottom to the top, and its minimum inner diameter is equal to the inner diameter of the sheath 4 and the lower joint 7; the pipe wall of the main body joint 1 is also provided with an installation hole penetrating the pipe wall , the installation hole is equipped with a check valve 2, so that the main body joint 1 is unidirectionally conducted from the outside of the pipe wall to the inside of the pipe wall.

[0017] The downhole washable well water injection insertion pipe sealing device of this embodiment can be used in backwash well ...

Embodiment 2

[0023] On the basis of Example 1, this example is further described. In this example, the inner wall of the main body joint 1 is annular and stepped from bottom to top, and the inner diameter of the lowermost stepped ring is equal to that of the sheath 4 and the lower joint 7. the inside diameter of. The annular stepped shape makes the inner wall of the main body joint 1 and the cannula 15 not in contact with each other, so that the cleaning fluid passes through the check valve 2 to clean the scaling and sediment at the sealing part of the cannula sealing device 10, Conditions and space are provided.

[0024] In order to ensure the sealing of the overall device, in this embodiment, the lower part of the inner wall of the main body joint 1 and the upper part of the inner wall of the lower joint 7 are provided with dust-proof rings 3, and the upper and lower parts of the inner wall of the sheath 4 are equipped with sealing gaskets 5 , Gasket 5-position V-shaped composite gasket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com