Special-shaped rubber shock absorber

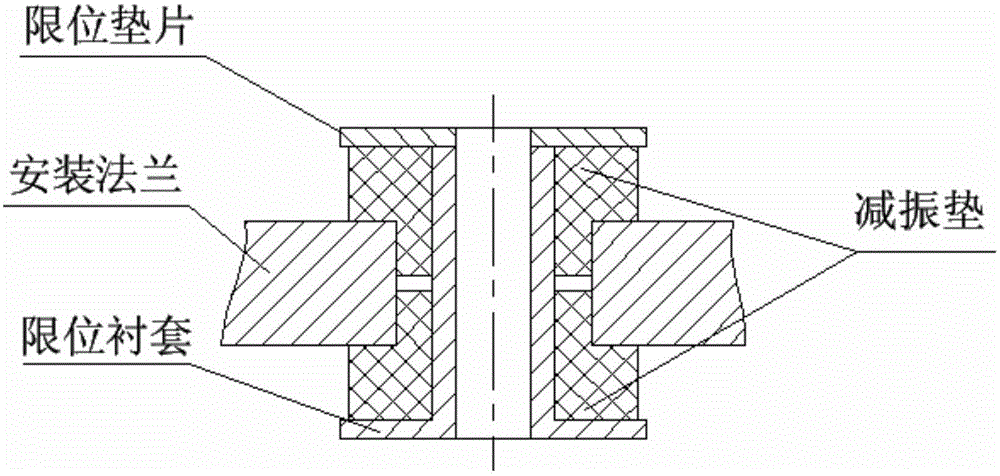

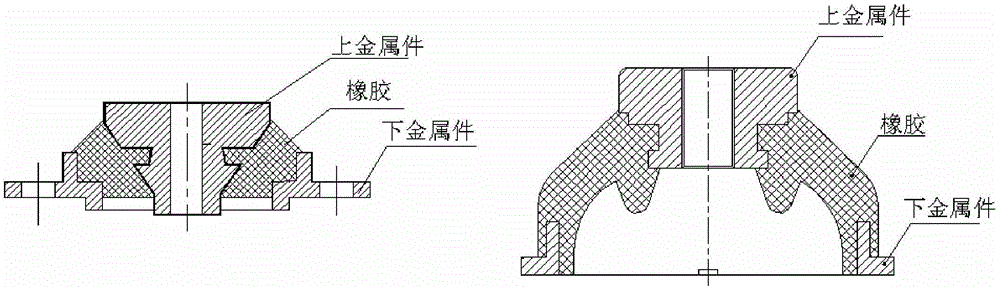

A rubber damper and rubber damping technology, applied in inertial effect dampers and other directions, can solve the problems of reducing vibration damping, buffering effect, large installation space, not meeting the requirements of lightweight equipment, etc., to improve damping. Vibration isolation and buffering effect, good damping vibration reduction and buffering effect, the effect of saving installation space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

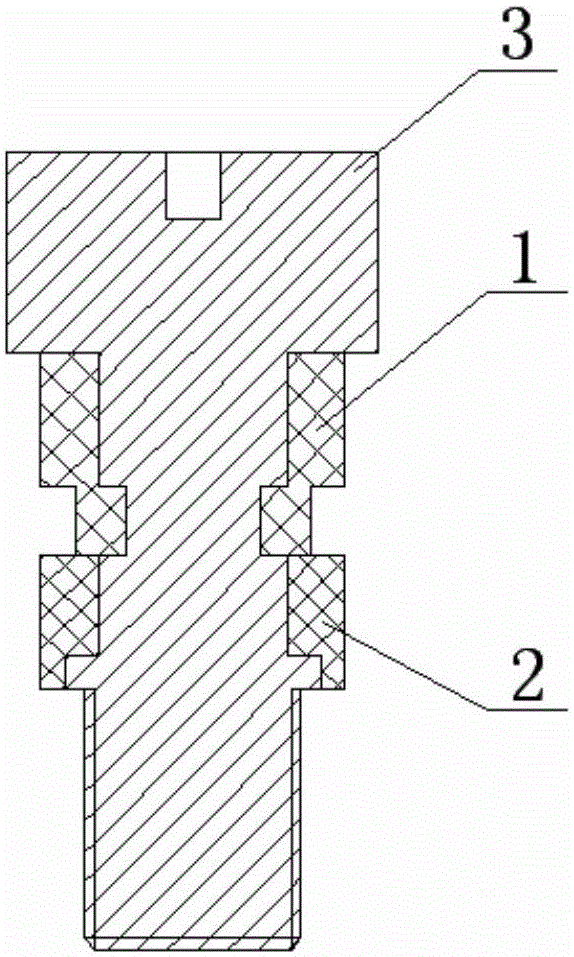

[0037] This embodiment is applied to the damping and vibration reduction of an electronic printed board. The weight of the printed board is about 150g, the overall size is 130mm*80mm, and the thickness is 1mm. The printed board passes through 8 through holes with a diameter of 3.5mm and M3 bolts Fixed on the mounting bracket, where two capacitor pins break under dynamic load conditions. On the basis of making full use of the gap between the M3 bolt and the φ3.5mm through hole, six special-shaped rubber shock absorbers of the present invention are installed on both sides and the middle of the printed board; in this embodiment, the variable-section rubber shock absorber ( 1) and the rubber damping flat pad (2) have a dynamic modulus of elasticity of 2.3Mpa, the inner diameter (D1) of the small diameter part is 70% of the diameter (M) of the lower threaded part of the special-shaped bolt (3), and the thickness of the groove (H3) is 25% of the total thickness H4 of the damping fla...

Embodiment 2

[0039] This embodiment is applied to the damping and vibration reduction of an electronic excitation board. The weight of the excitation board is about 240g, the external dimension is 140mm*120mm, and the thickness is 2mm. On the support, its circuit fails under dynamic load conditions. 4 special-shaped rubber shock absorbers of the present invention are installed on the excitation plate. In the present embodiment, the dynamic modulus of elasticity of the material of the variable-section rubber shock absorber (1) and the rubber shock absorber flat pad (2) is 2.3Mpa, and the inner diameter of the small diameter part The dimension (D1) is 75% of the diameter (M) of the lower threaded part of the special-shaped bolt (3), the thickness of the groove (H3) is 30% of the total thickness H4 of the damping flat pad (2), and the diameter of the groove (D5) 0.4mm larger than the diameter (M) of the lower part of the threaded part of the special-shaped bolt (3), the thickness (H) of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic modulus of elasticity | aaaaa | aaaaa |

| Dynamic modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com