Inner rotor motor wave-shaped friction transmission self-adaption automatic variable speed drive assembly of electric motor car

A technology of inner rotor motors and electric motorcycles, which is applied to transmission parts, transmission control, mechanical equipment, etc., can solve problems such as tolerances, and achieve the effects of improving safety, increasing friction surfaces, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

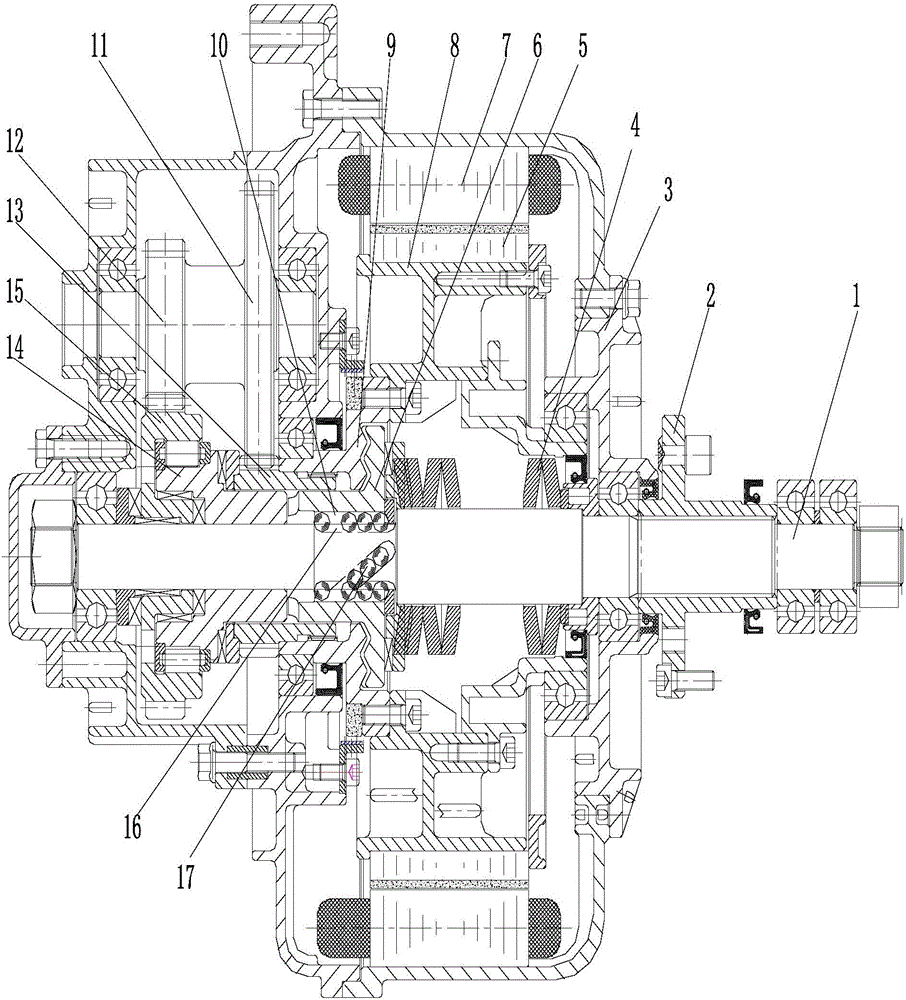

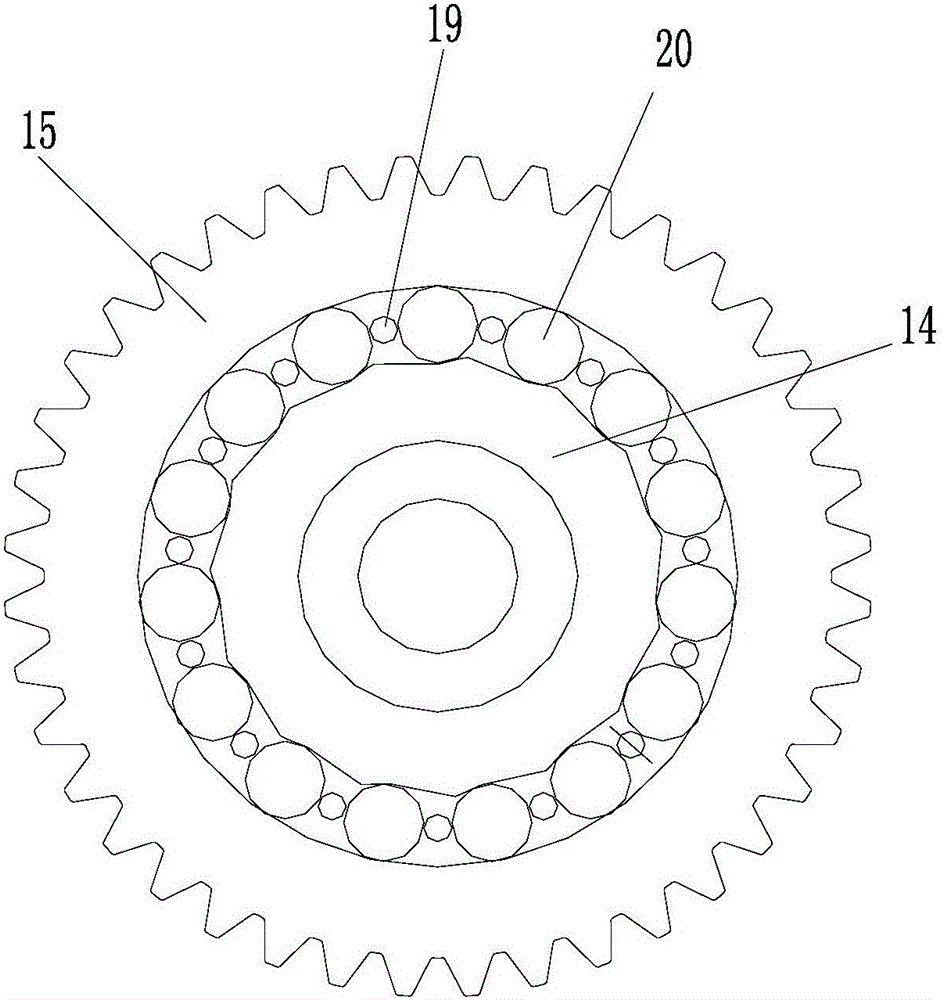

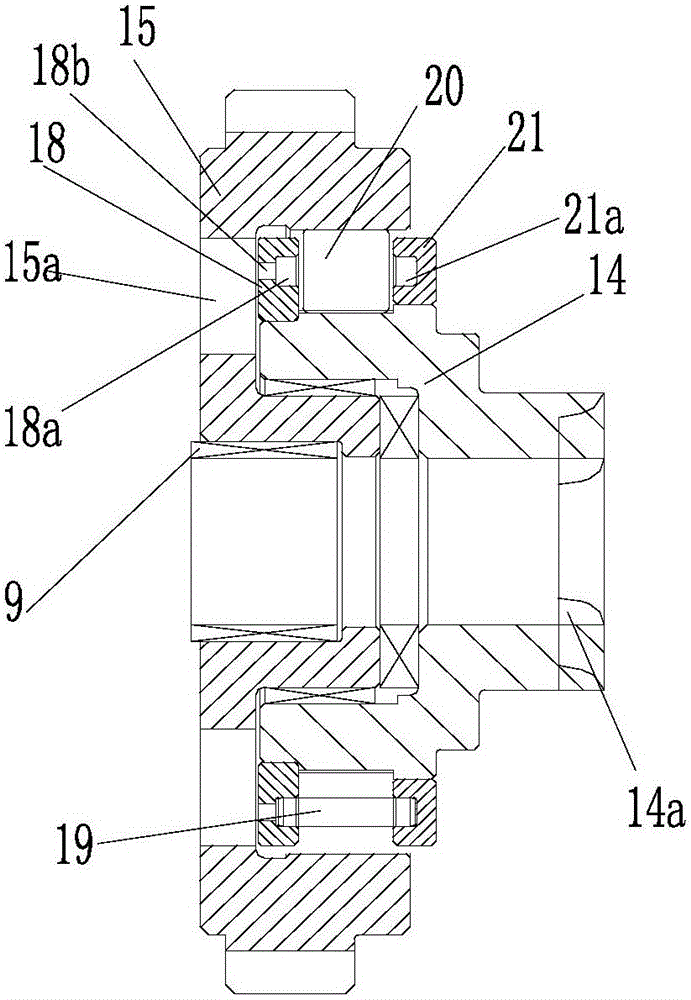

[0024] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 Schematic diagram of the structure of the overrunning clutch, image 3 It is a circumferential sectional view of the overrunning clutch, as shown in the figure: the wave-shaped friction transmission adaptive automatic variable speed drive assembly of the electric motorcycle inner rotor motor of the present invention, the two-speed adaptive automatic variable speed drive assembly of the inner rotor motor of the present invention, It includes a drive motor, a box body, and a drive shaft 1 that rotates with the box body and outputs the power. The box body has a mounting portion for side hanging on the hub side, or a mounting portion for directly forming the hub, here No more details; it also includes a slow gear transmission mechanism and a mechanical intelligent adaptive transmission assembly arranged on the transmission shaft 1;

[0025] The mechanical intelligent self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com