Manufacturing and mounting process for composite phenolic aldehyde aluminum foil air pipes

A composite air duct and installation process technology, applied in the direction of pipes, rigid pipes, pipeline layout, etc., can solve the problems of high production cost, long installation period, poor thermal insulation performance and appearance, etc., and achieves exquisite production process, production and installation speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

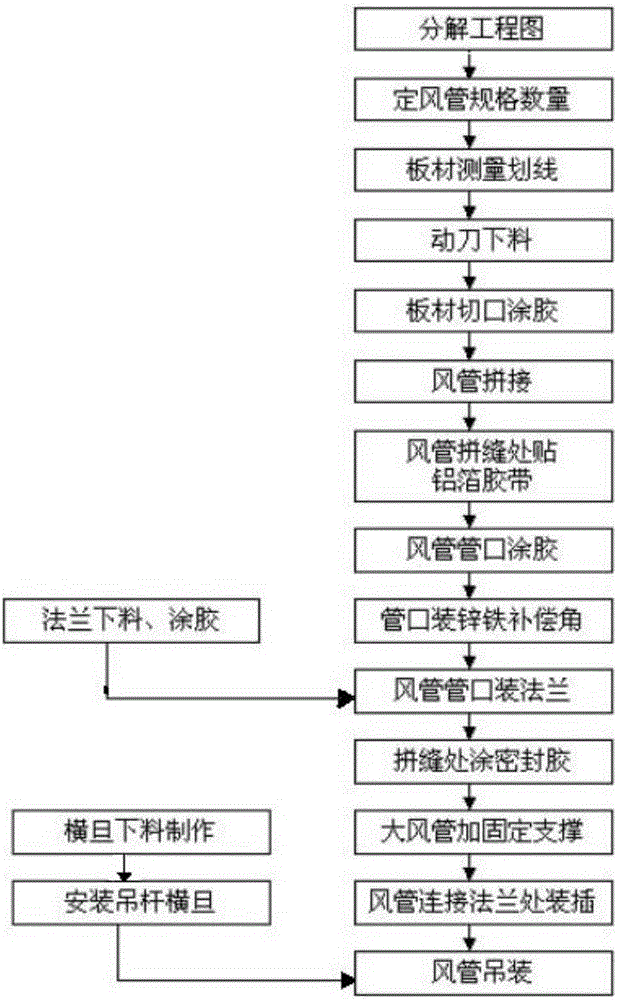

[0010] The production and installation process of phenolic aluminum foil composite air duct, the process steps are:

[0011] In the early stage, the engineering drawings were drawn according to the construction site, and the engineering drawings were disassembled to determine the installation positions of the air-conditioning equipment and air duct components. The quantity of air duct specifications, that is, the reasonable length and quantity of straight air ducts and special-shaped ducts, is measured and marked on the plate, and rectangular straight air ducts and T-shaped rectangular air ducts are staked out. Measure with a steel ruler, use a paintbrush and square aluminum Draw the cut-off line, V-shaped groove line, and 45-degree slope line with the alloy ruler, make the lofting of rectangular bend pipe, rectangular reducer pipe and rectangular bifurcated pipe, and draw the cut-off line, 45-degree slope line, and bending line Or V-shaped groove line, move the knife along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com