Device and method for measuring thickness of scale on metal surface

A metal surface and measurement method technology, applied in electromagnetic measurement devices, electric/magnetic thickness measurement, etc., can solve the problems of difficult to achieve acoustic coupling, inability to achieve online measurement of scale thickness, etc., and achieve the effect of convenient integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

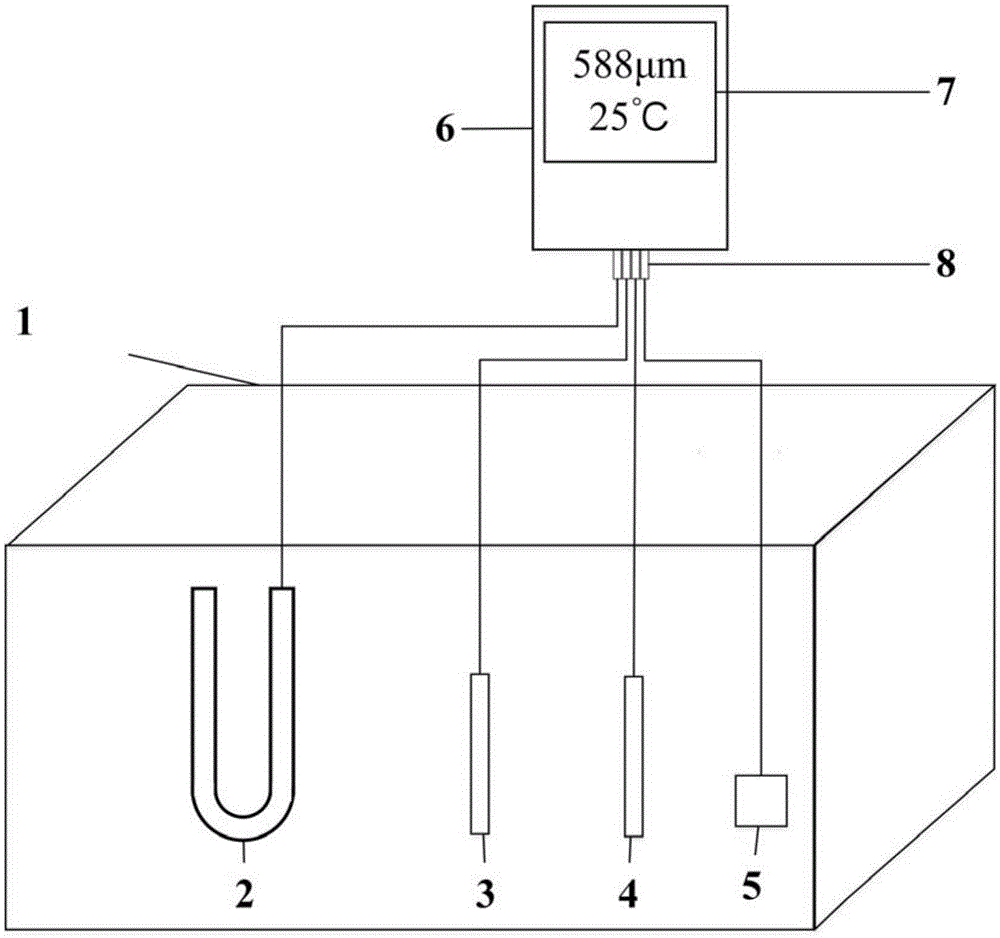

[0078] The metal parts are Qingfeng F1 anti-dry burning U-shaped heating tubes that heat quickly. The first auxiliary electrode and the second auxiliary electrode are stainless steel rods, and they are immersed in tap water together with the temperature sensor. Calibrate U-shaped heating tubes with thicknesses of 0 μm, 137 μm, 267 μm, 413 μm, 588 μm, and 643 μm, the temperature range of the solution is 0-100 °C, and the interval is 2 °C, and the calibration data is stored in the table.

[0079]For a U-shaped heating tube with an unknown scale thickness, the measured solution temperature is 22.5°C and ΔV is 16mV. Using one-dimensional interpolation, look up the thickness-ΔV data in the storage table when the corresponding solution temperature is 22°C, as shown in Table 1.

[0080] Table 1. Thickness-ΔV data at 22°C

[0081]

1

2

3

4

5

6

7

Thickness / μm

0

137

267

413

475

588

643

ΔV / mV

2

4

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com