Anti-vibration pressure sensor resistant to transient oil pressure impact

A pressure sensor, anti-vibration technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of output distortion, pressure-sensitive core damage, etc., to increase the layout area, improve the resistance The effect of vibrating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

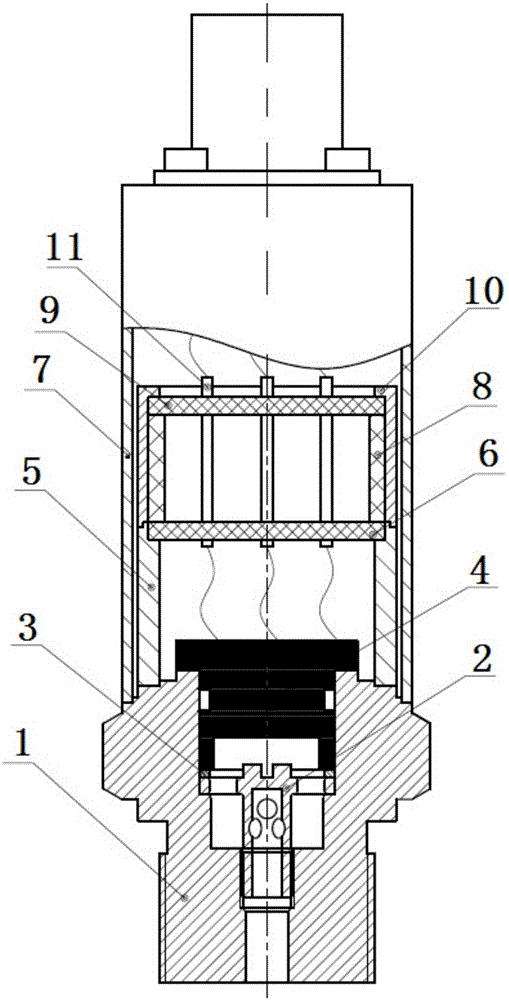

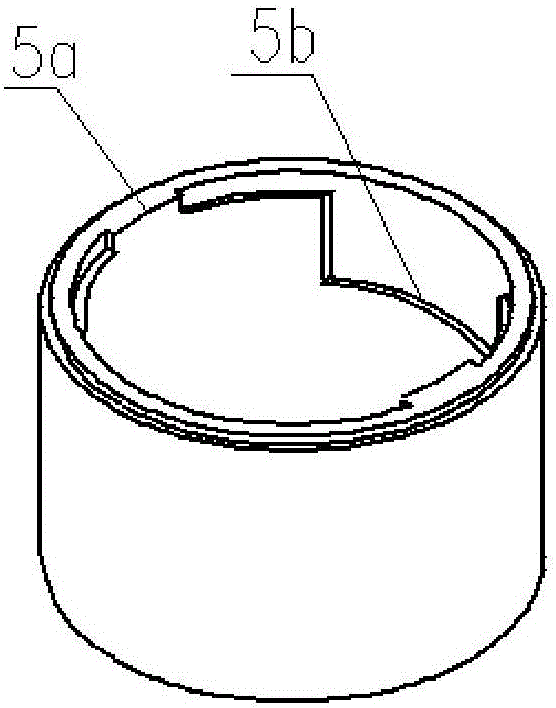

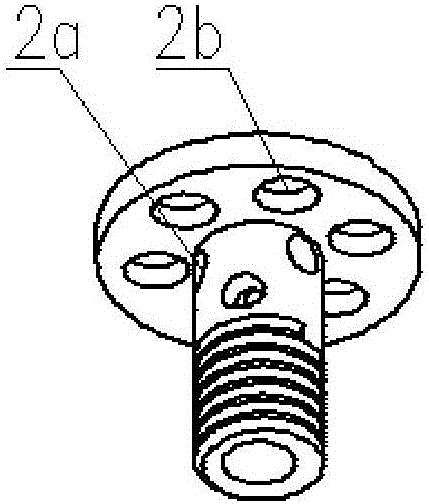

[0030] A pressure sensor that is resistant to vibration and instantaneous oil pressure shock, such as figure 1 As shown, it includes a base 1 and a shell 7, the inner wall of the pressure introduction hole of the base 1 is screwed to the buffer 2, the top of the base 1 is welded to the core 4; the core 4 and the buffer 2 are connected by a pad The sheet 3 is compressed to achieve flexible connection; the lower end of the lower ring 5 is welded into one body with the base 1, and the lower ring 5 is provided with a positioning slot for the lower circuit board 6 inside, such as figure 2 As shown, the positioning structure is a boss 5a arranged on the inner wall of the lower ring 5; the inner wall of the lower ring 5 is also provided with a groove 5b to avoid welding spots; the upper end of the lower ring 5 is welded to the upper ring 10 Integral, the upper circuit board 9 and the lower circuit board 6 are insulated by the insulating ring 8, electrically connected and fixed by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com