Method for measuring rotating speed of reciprocating-type refrigeration compressor

A technology for measuring the speed of refrigeration compressors, applied to devices using fluids, etc., can solve the problems of measurement devices and accuracy limitations, non-compliance with the measurement principles, compressor damage, etc., to achieve improved accuracy, simple devices, and avoid The effect of intermediate errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

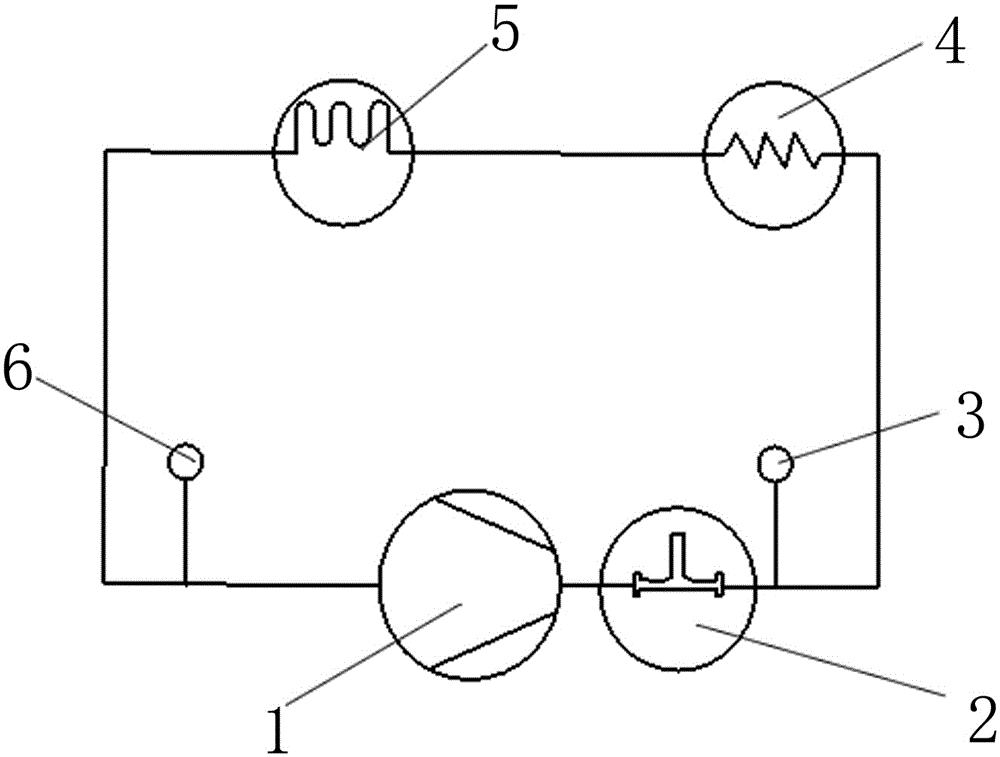

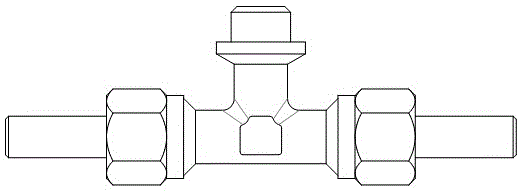

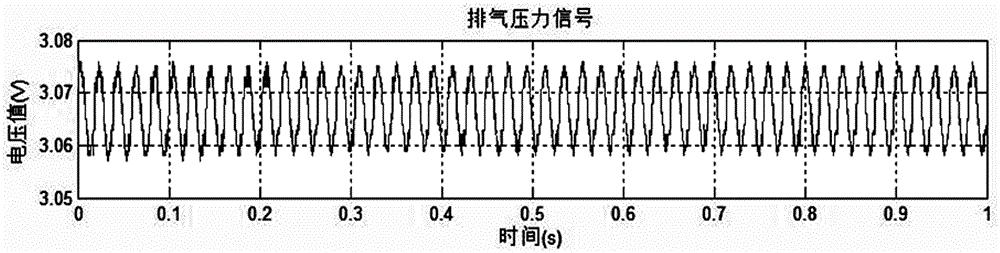

[0035] The present invention is composed of test hardware part and software part. The hardware part includes a small reciprocating refrigeration compressor, Advantech high-speed acquisition card PCI-1715U, GY403 pressure sensor, and Advantech industrial computer. The software part is written by the LABVIEW graphical development software. Since a large number of mathematical operations are required, MATLAB scripts are added to the labview programming to facilitate fast calculations. The test software is mainly composed of data acquisition, signal processing, and result display. LabVIEW is a graphical programming language that uses charts instead of text lines to create applications. It changes the traditional text programming language to determine the execution order of programs based on the order of statements and instructions. It adopts data flow programming. Nodes in the block diagram The data flow direction of the program determines the execution sequence of the program. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com