STL triangular patch top-point isometric offset based incrementally formed support body generation method

A progressive forming and triangular piece technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of support body gap error, complex algorithm, and difficult determination of weight value, etc., to ensure processing quality, Improved processing quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] The invention relates to a method for generating a progressively formed support body based on the equidistant offset of the vertices of the STL triangular piece, comprising the following steps:

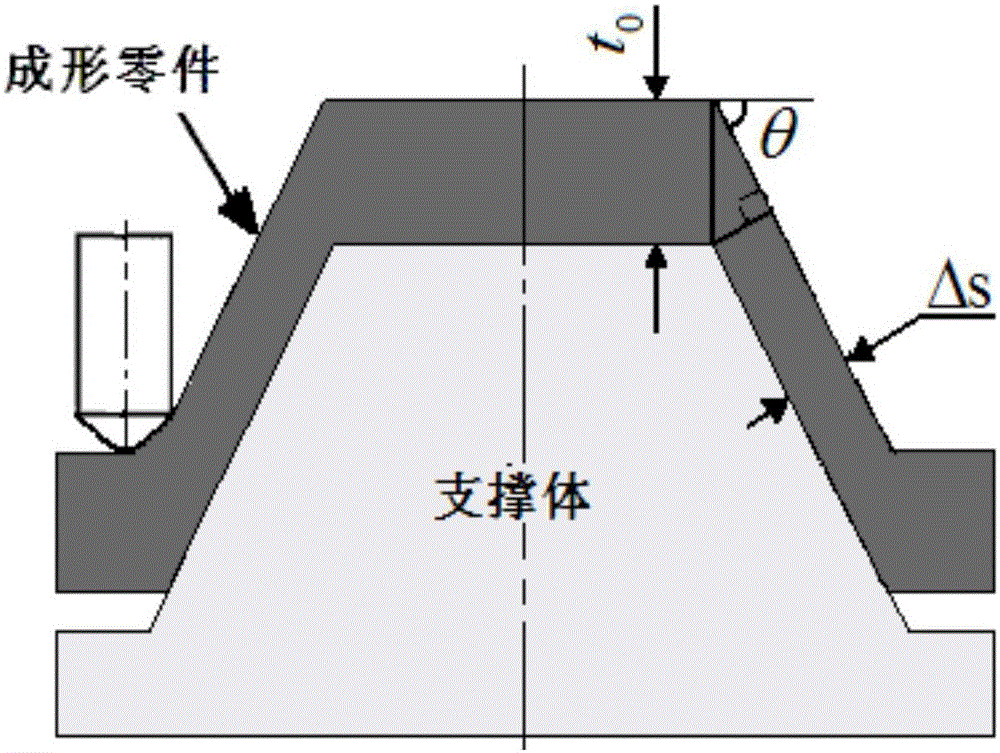

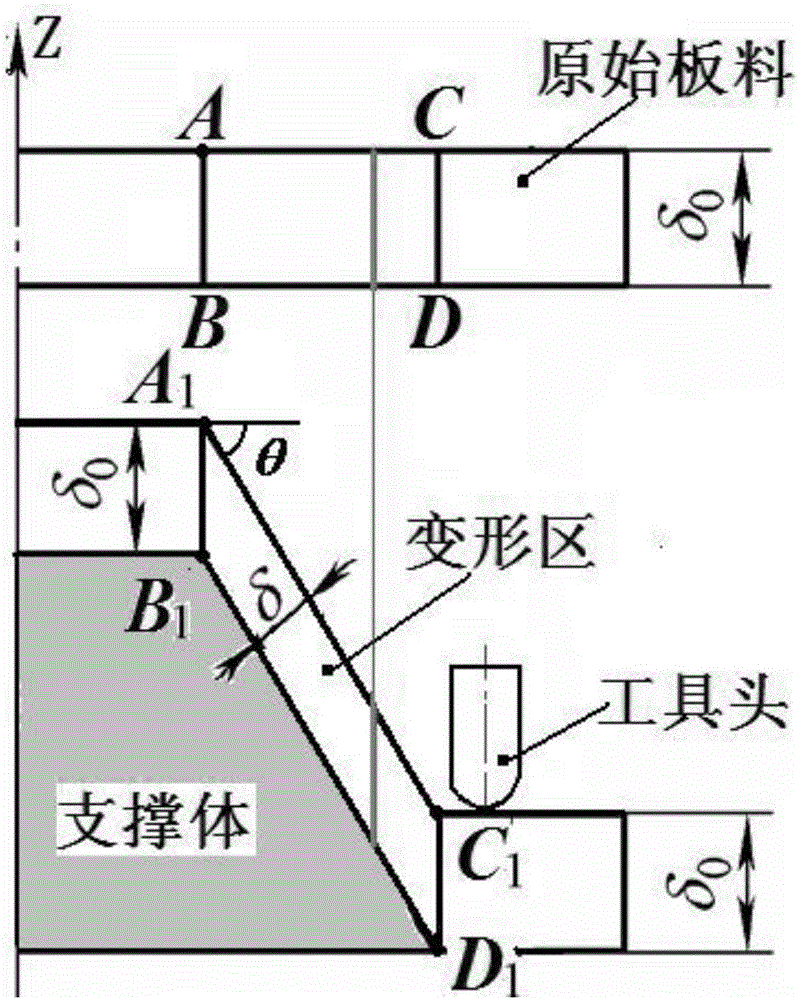

[0024] 1) Determine the main direction of the progressive forming of the part so that the forming angle θ of each position does not exceed the forming limit angle θ of the sheet max .

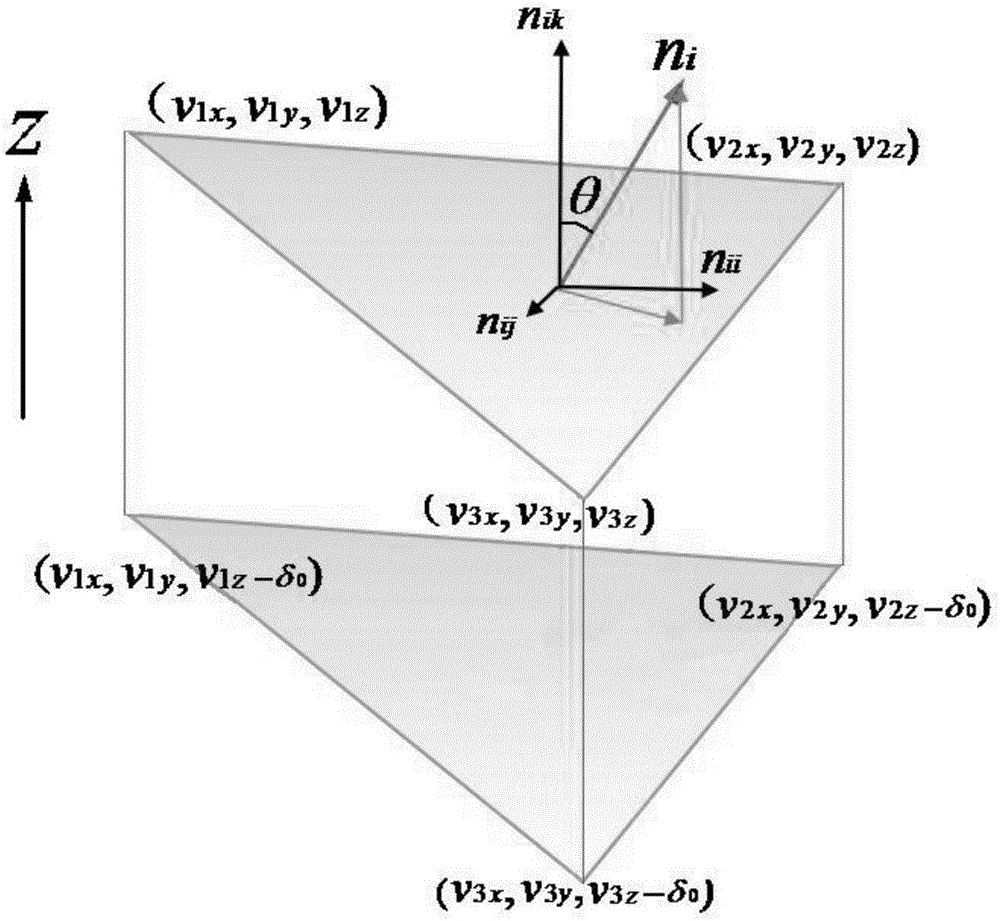

[0025] 2) Extract the upper surface of the part model and generate the corresponding STL format file; the STL format file is generated on the CAD platform with a certain triangular tolerance and adjacent tolerance accuracy; the selected triangular tolerance and adjacent tolerance are selected based on empirical v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com