rotor for electric motor

A motor and rotor technology, applied in the field of rotors used in motors, to achieve the effect of simplifying the manufacturing process, simple and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The same parts are provided with the same reference numerals in all figures.

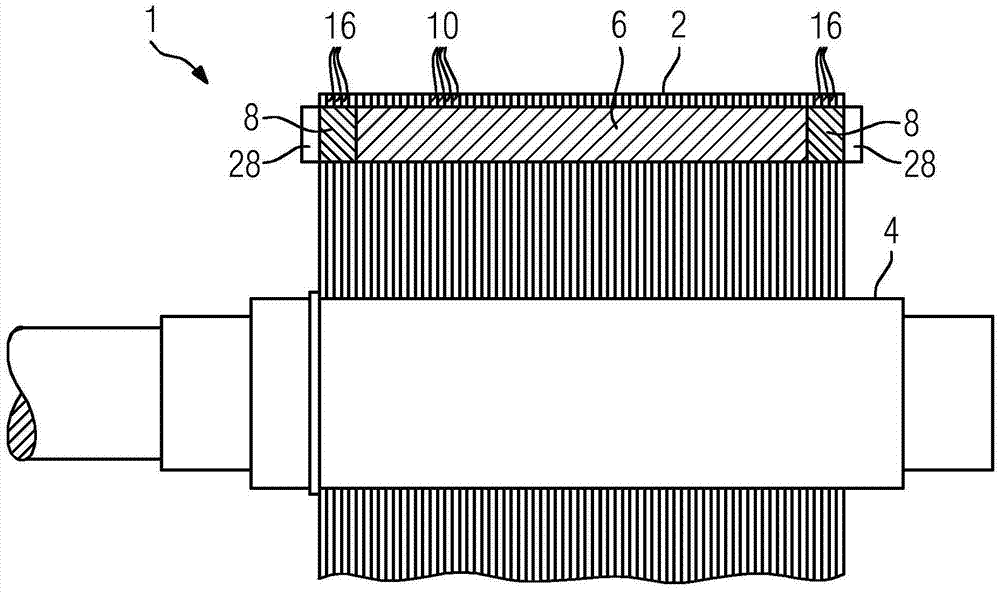

[0030] figure 1 A rotor 1 for an electric motor is shown. It is designed as a cage rotor and has a short-circuited cage running in the laminated core 2 instead of a coil wound from wire and supplied via slip rings, as in slip ring rotor motors. The rotor 1 comprises a laminated core 2 made of iron, arranged on a shaft 4 , into which metal rods 6 made of a non-ferrous metal, such as copper or aluminum, are inserted. The metal rod 6 extends substantially in the axial direction, however it is slightly inclined in the circumferential direction with respect to the axial direction. It is connected at the axial end of the laminated core 2 to a surrounding short-circuit ring 8 .

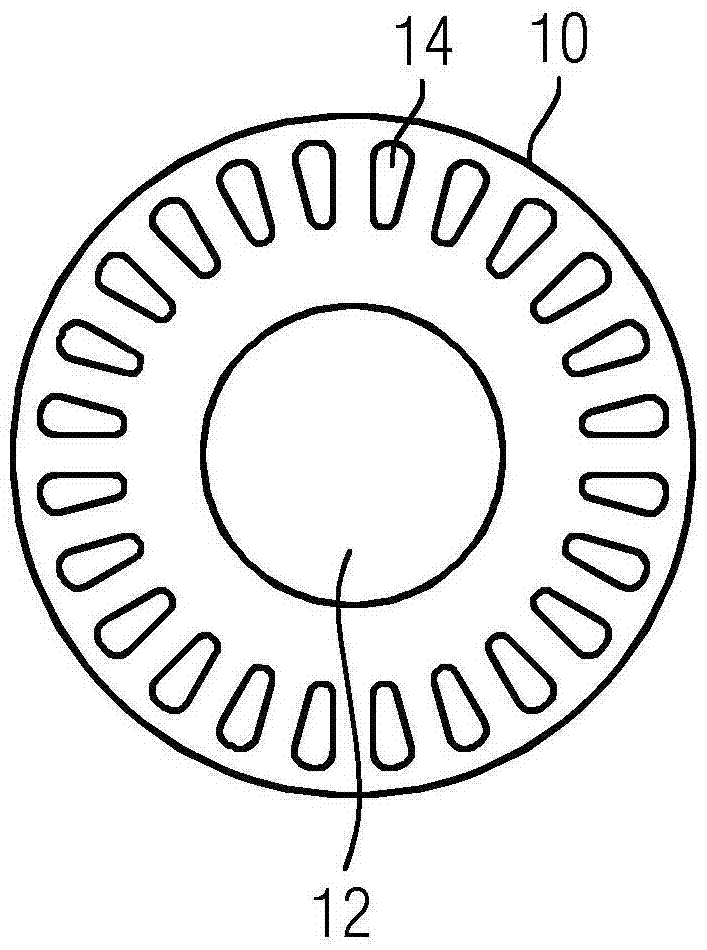

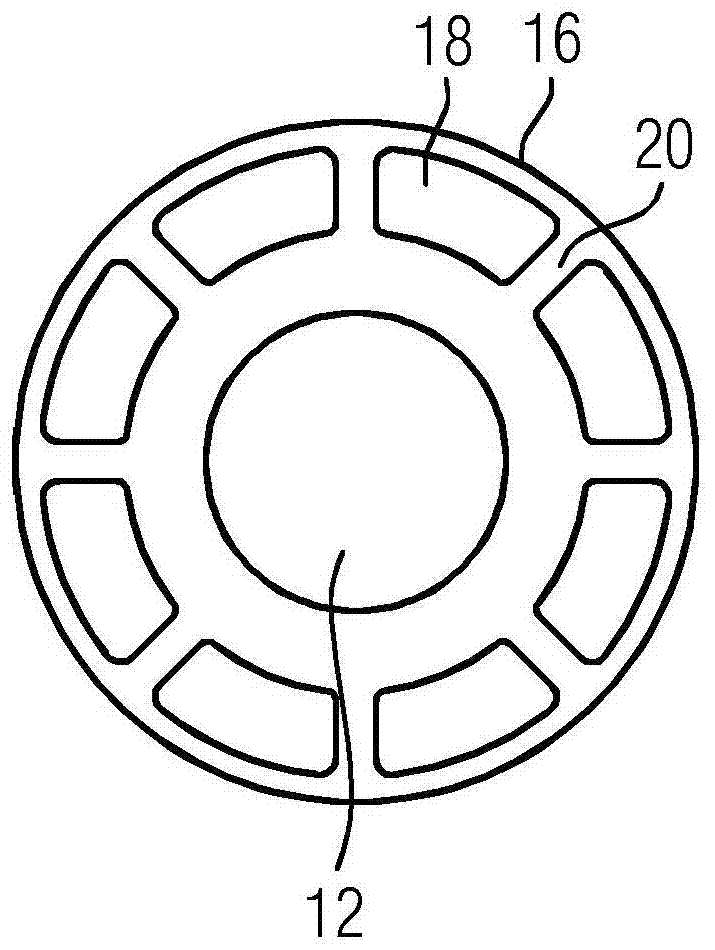

[0031] The lamination pack 2 consists of individual laminations, which are insulated from one another, into which cutouts for receiving the metal rods 6 are stamped. this is in figure 2 and 3 is further shown in . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com