Dried mulberry fruit product manufacturing method

A production method and technology of dry products, which are applied in confectionary, confectionary industry, food science, etc., can solve problems that affect people's consumption, browning, and bad taste, and achieve easy promotion, better taste, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

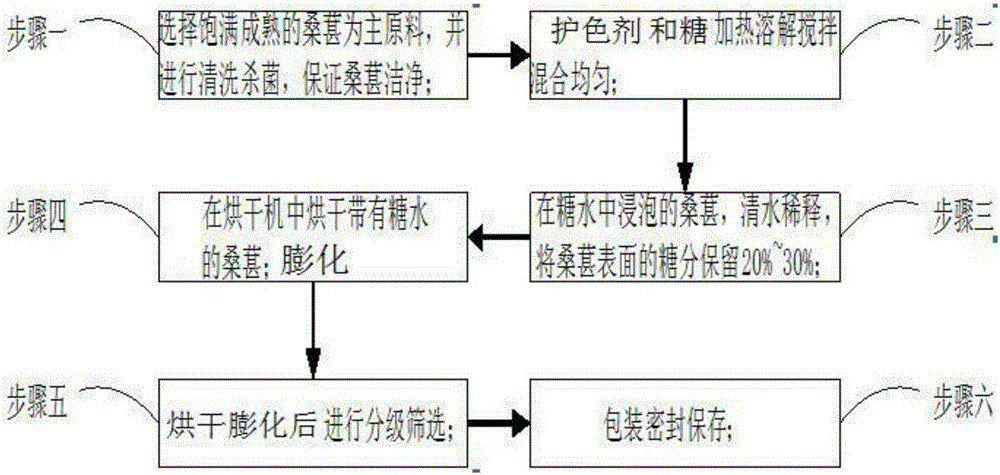

[0025] Please refer to the attached figure 1 , in the embodiment of the present invention, the preparation method of dry mulberry product comprises step 1, selects plump and mature mulberry as the main raw material, and cleans and sterilizes to ensure the cleanness of mulberry; Heat, dissolve, and mix evenly; step 3, dilute the mulberry soaked in sugar water with water, and keep 20% to 30% of the sugar on the surface of the mulberry; step 4, dry the mulberry with sugar water in a dryer; step 5 , after drying, the mulberries are graded and screened; step 6, packaged and sealed for preservation; it is characterized in that:

[0026] In step 1, when the mulberry is being cleaned, surface impurities and pesticides are removed to ensure a cleanliness of more than 90%; in step 2, refined white sugar is stirred in hot water to mix sugar water with a concentration of preferably 60% to 70% In step three, it is advisable to keep 25% of the sugar content; in step four, a 766-3AS vacuum ...

Embodiment 2

[0033] The preparation method of dried mulberry product is the same as in Example 1, wherein the formula of color-protecting agent is optimized.

[0034] In order to maintain the color of the fruit, soak in sugar water and add color-protecting agents such as citric acid to form an optimized color-protecting agent formula.

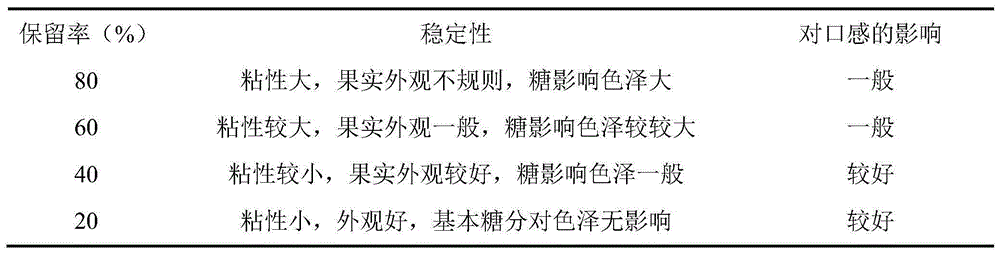

[0035] Table 2 color protectant level table

[0036]

[0037] Table 3 visual analysis table

[0038]

[0039] From the mean values in Table (14), we can see that the theoretical optimal combination should be A2B2C3D2. Instant sugar 60%, citric acid 0.04%, isovitamin C 0.08%, L-cysteine 0.03%.

Embodiment 3

[0041] The method for preparing dried mulberry products is the same as in Example 1, except that the conditions in the drying stage are optimized.

[0042] 2. The drying equipment adopts far-infrared vacuum dryer.

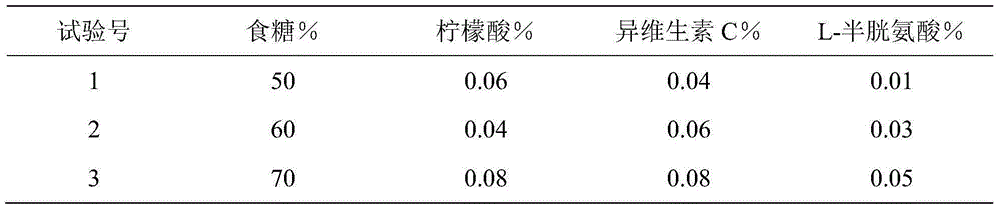

[0043] Table 4 level table

[0044]

[0045]

[0046] Table 5 visual analysis table

[0047]

[0048] The best combination is A2B2C2, power density 5W / g, vacuum degree 0.06MPa, irradiation distance 170mm.

[0049] The mulberry produced by adopting the above technical scheme has a better taste and satisfies people's consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com