Garlic product and production method thereof

A production method and garlic technology, applied in the food field, can solve problems such as strong garlic taste, and achieve the effects of good taste, enhanced bactericidal effect, and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

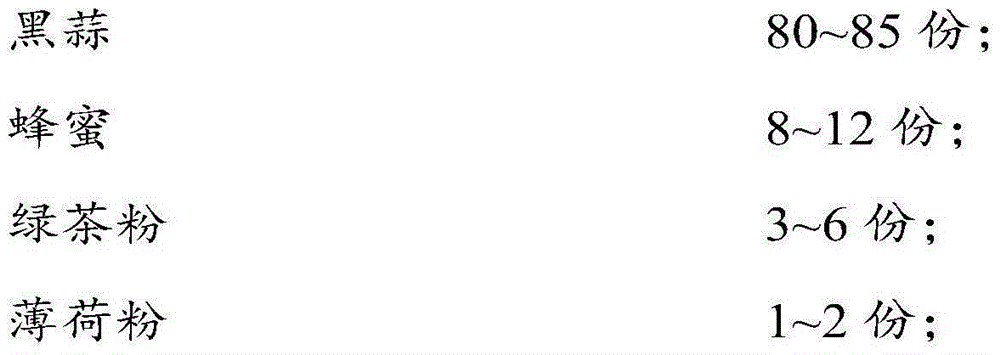

[0035] A garlic product comprising the following components:

[0036]

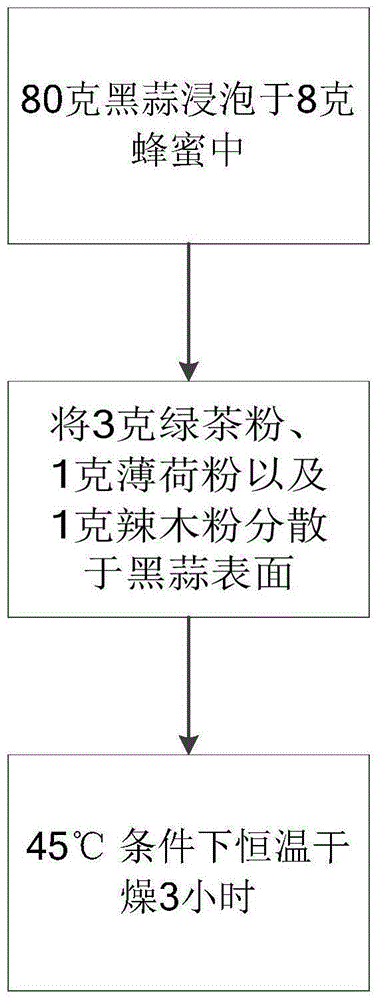

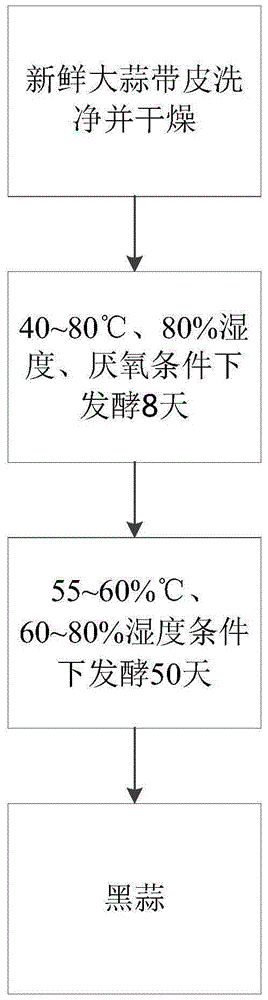

[0037] refer to figure 1 , the garlic product is made by the following method:

[0038] Step 1, weighing each raw material according to the above weight, soaking the black garlic in honey, and taking out the black garlic after the black garlic is fully soaked in the honey. In step 2, green tea powder, peppermint powder, and Moringa powder are mixed into an auxiliary material powder, and the auxiliary material powder is evenly dispersed on the surface of the black garlic. Step 3, drying the powder-coated black garlic in a thermostat at 45° C. for 3 hours, and then naturally cooling to room temperature to obtain a garlic product. The mint powder is preferably made by pulverizing mint leaves to improve the quality and mouthfeel of the mint powder; the green tea powder is preferably made by pulverizing green tea leaves. The black garlic is directly purchased from the market, and the one with the highest ...

Embodiment 2

[0044] A garlic product comprising the following components:

[0045]

[0046] The garlic product is made by the following methods:

[0047] Step 1, weighing each raw material according to the above weight, soaking the black garlic in honey for 22 hours, and taking out the black garlic after the black garlic is fully soaked in the honey. In step 2, green tea powder, peppermint powder, and Moringa powder are mixed into an auxiliary material powder, and the auxiliary material powder is evenly dispersed on the surface of the black garlic. Step 3, drying the black garlic coated with powder in a constant temperature box at 40° C. for 33 hours, and then naturally cooling to room temperature to obtain a garlic product.

Embodiment 3

[0049] A garlic product comprising the following components:

[0050]

[0051]The garlic product is made by the following methods:

[0052] Step 1, weighing each raw material according to the above weight, soaking the black garlic in honey for 12 hours, and taking out the black garlic after the black garlic is fully soaked in the honey. In step 2, green tea powder, peppermint powder, and Moringa powder are mixed into an auxiliary material powder, and the auxiliary material powder is evenly dispersed on the surface of the black garlic. Step 3, drying the black garlic coated with powder in a constant temperature box at 45° C. for 5 hours, and then naturally cooling to room temperature to obtain a garlic product.

[0053] Before the black garlic is soaked in honey, the black garlic is first punctured. In this embodiment, the black garlic is punctured with a bed of nails. The average number of holes in the black garlic is 10-20. Because the black garlic is punctured, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com