Control system for microwave tobacco stem expanding equipment

A control system and tobacco stem technology, applied in the fields of tobacco, tobacco processing, and application, can solve the problems of insufficient understanding of the discrete characteristics of microwave devices, damage to the uniformity of the electric field in the applicator, and reducing the overall power density of the applicator, so as to improve the operation. Effects of speed and reliability, simplification of control algorithm, expansion rate and expansion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

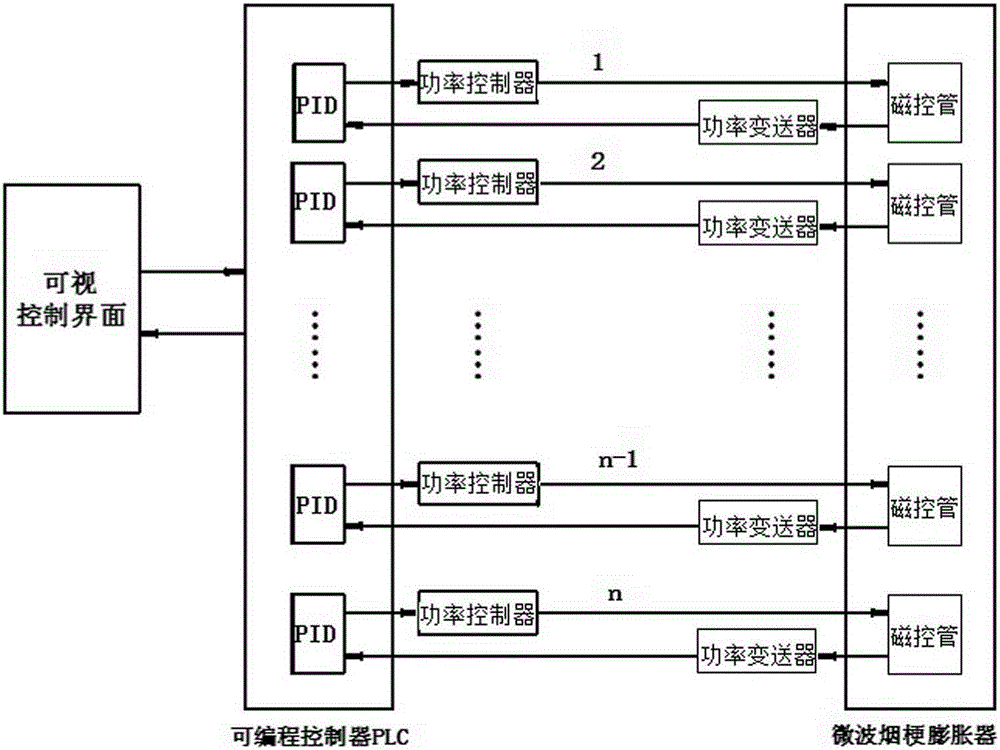

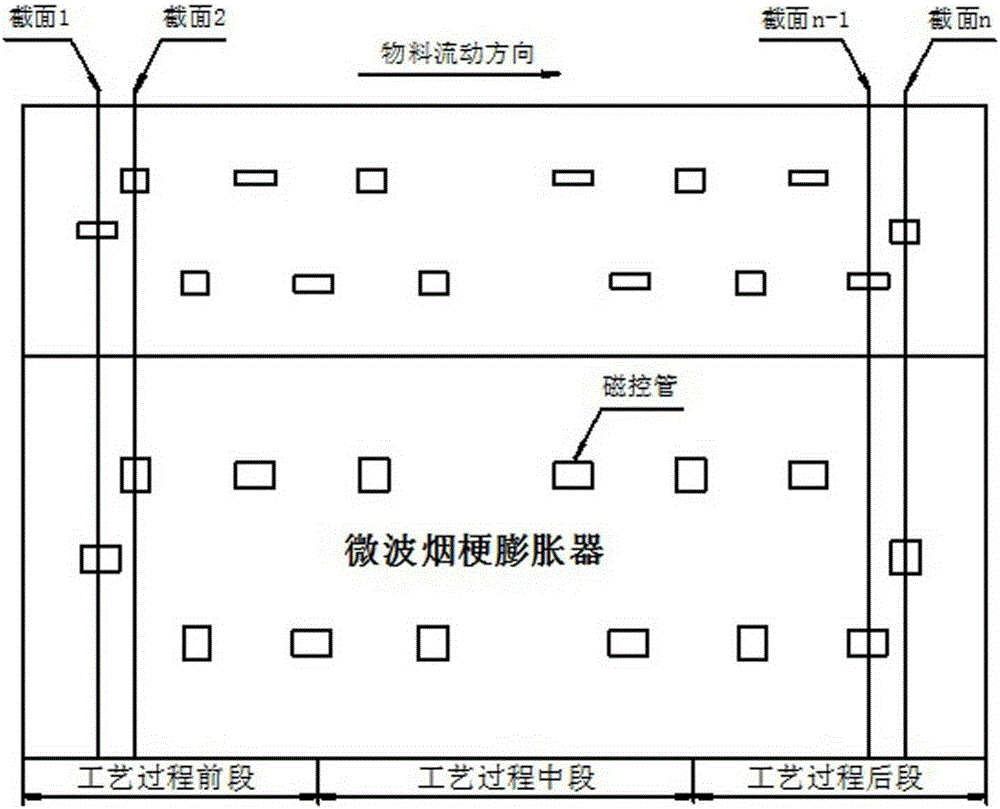

[0010] Such as figure 1 As shown, the control system of a microwave tobacco stem expansion device of the present invention includes a programmable controller PLC, a visual control interface connected to the programmable controller PLC, and a group of programmable control devices installed in the microwave tobacco stem expander. The magnetron connected to the PLC; the programmable controller PLC includes a group of PID controllers (soft control elements in the PLC), and adopts a one-to-one power closed-loop control system to continuously adjust and control the power of the microwave tobacco stem expander ; Each power closed-loop control system is a loop composed of sequentially connected magnetrons, power transmitters, PID controllers, and power controllers. The specific number of loops n is determined according to the number of magnetrons required by the production output. The magnetrons are respectively arranged at the front section, the middle section and the back section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com