Breathable and durable sneaker vamp

A technology for sports shoes and uppers, which is applied in uppers, footwear, applications, etc. It can solve the problems of poor air permeability, thin structure, and easy cracking, and achieve the effect of tight combination, not easy to enter water, and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

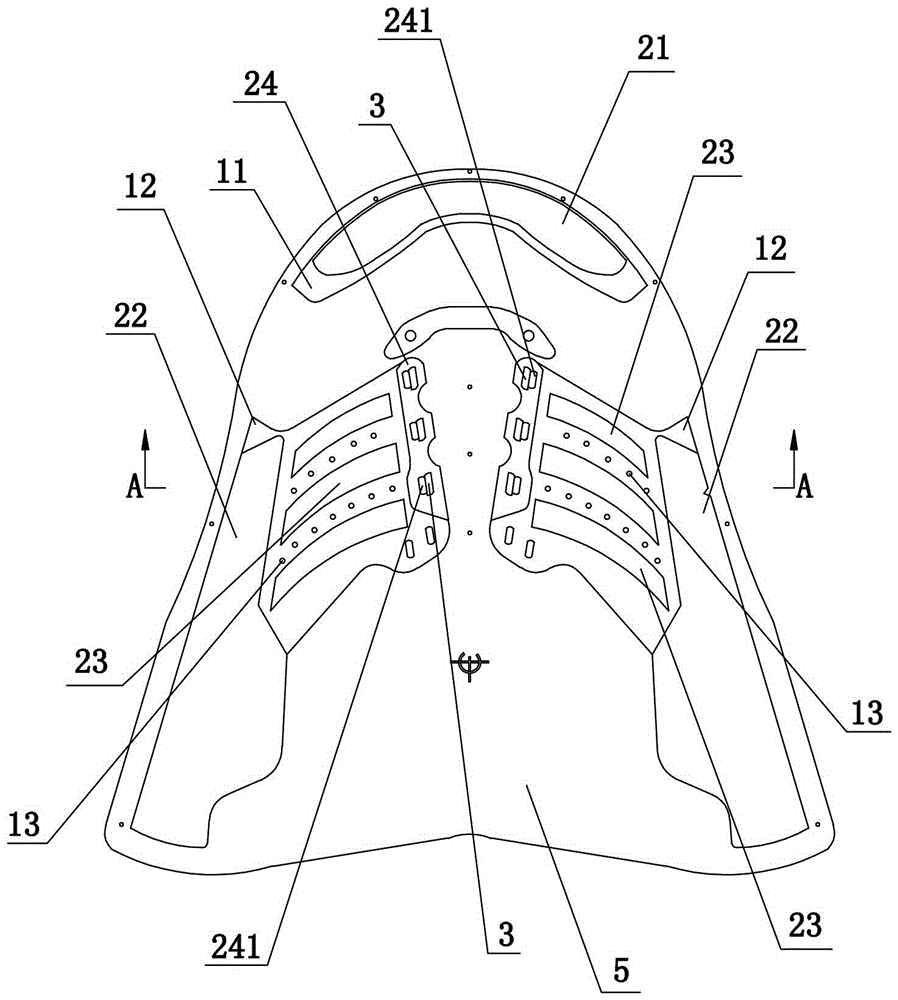

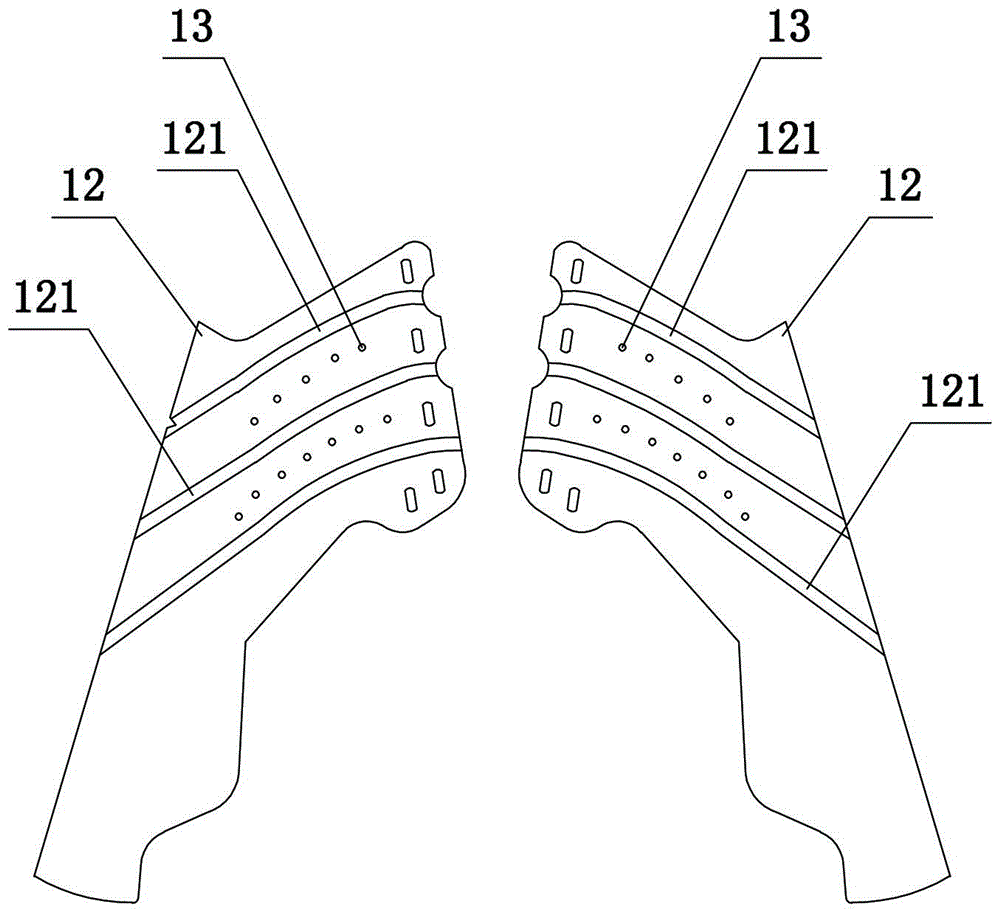

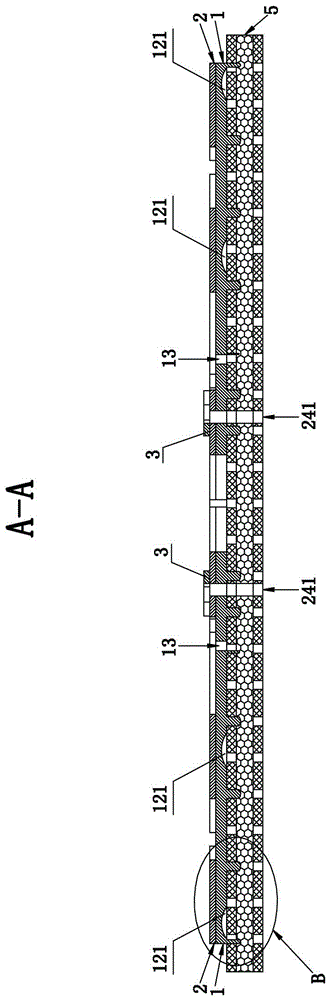

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , a breathable and durable sports shoe upper, comprising a substrate layer 5 , a first printing layer 1 , a second printing layer 2 , and a third printing layer 3 . The above-mentioned base material layer 5 is a three-layer mesh cloth. The above-mentioned first printing layer 1 is made by screen printing and drying the water-based polyurethane paint 20 times. The above-mentioned second printing layer 2 is made by screen printing and drying the water-based polyurethane paint 10 times. The above-mentioned third printing layer 3 is made by screen printing and drying the water-based polyurethane paint 5 times. The first printing layer 1 is arranged on the upper surface of the substrate layer 5 , the lower surface of the first printing layer 1 is attached to the upper surface of the substrate la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com