Sewage treatment unit capable of effectively reducing COD suspended solids (SS)

A sewage treatment device and suspended solids technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of large pressing area, unsmooth water outlet channel, and small footprint, so as to increase water output and improve The effect of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

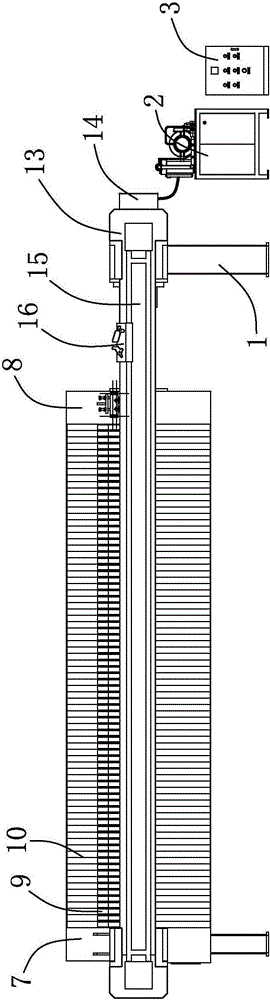

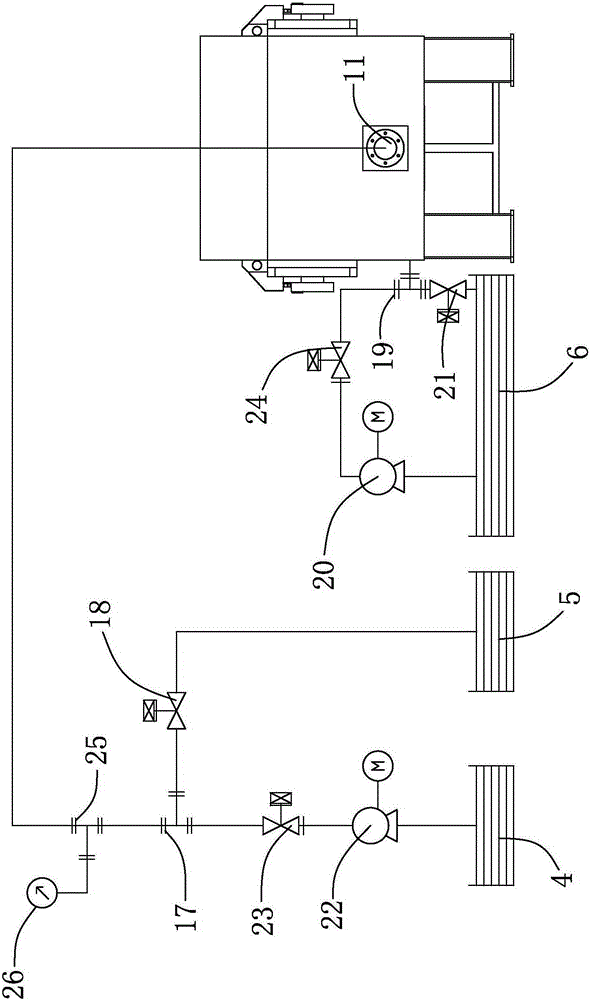

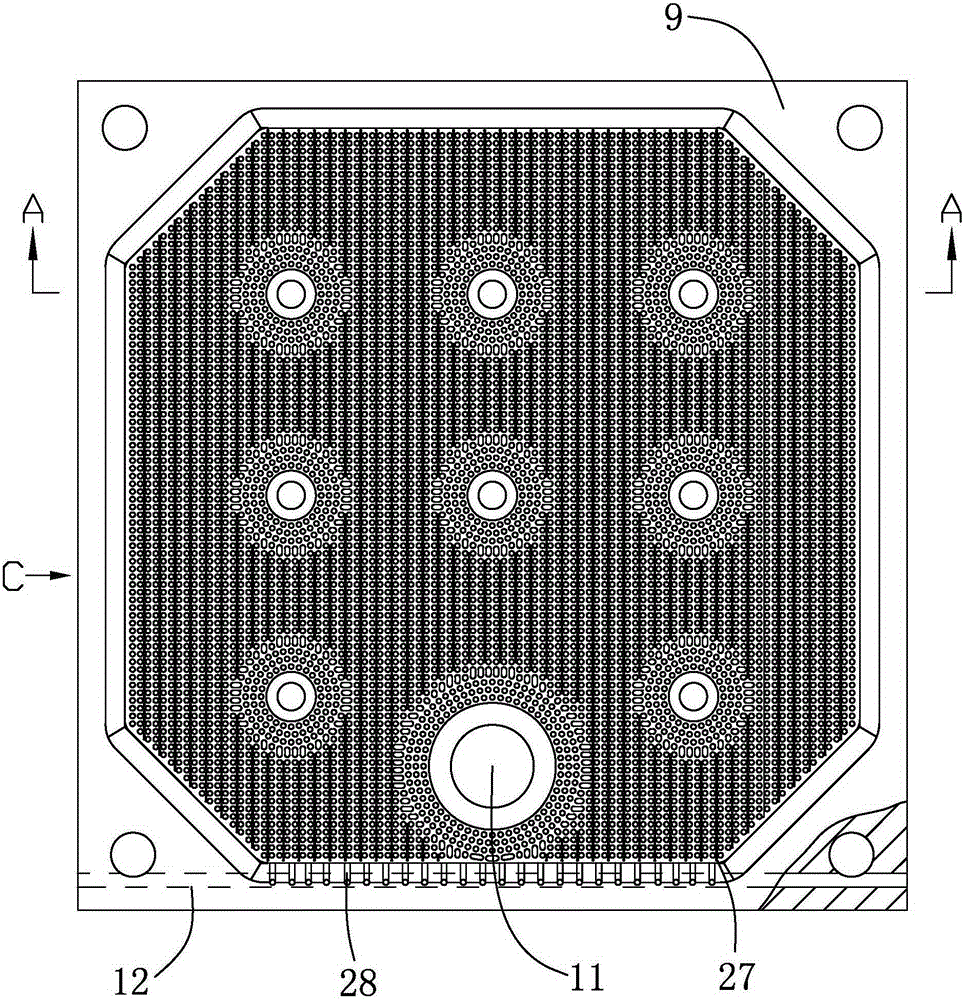

[0027] like Figure 1 to Figure 6 As shown, it is a sewage treatment device for effectively reducing COD suspended matter SS of the present invention, including a filter 1, a hydraulic workstation 2, an electric control box 3, a sewage tank 4, a sludge tank 5 and a clear liquid tank 6, and a hydraulic workstation 2 To supply energy for the filter 1, the electric control box 3 is equipped with a power indicator light, a pressure maintaining indicator light, a return indicator light, a pressing button, a return button, a pull button and an emergency stop button. The processing device controls and displays the working status. The filter 1 is provided with a thrust plate 7 and a pressing plate 8, a filter plate 9 and a filter cloth 10 are arranged between the thrust plate 7 and the pressing plate 8, a filter cavity is formed between the filter plates 9, and the filter cloth 10 is provided In the filter chamber, the filter plate 9 is provided with a liquid inlet 11, a water outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com