ore crushing unit

A technology of ore crushing and jaw crusher, which is applied in the field of ore crushing units and alloy ore crushing, can solve the problems of dust explosion, environmental pollution, high maintenance costs, etc., to prevent overheating of equipment, ensure a good production environment and a good site environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

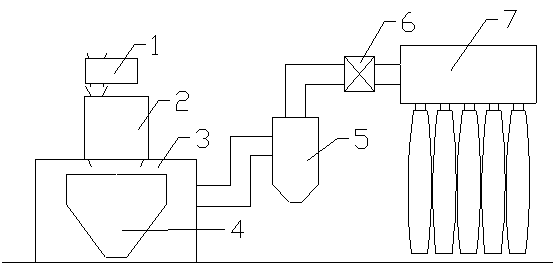

[0027] see figure 1 , the present invention relates to an ore crushing unit, which includes a crushing and dust removal device, and the crushing and dust removal device includes a jaw crusher 1, a hammer mill 2, a sealed bin 3, a collection bin 4, a Shacron dust collector 5, Fan 6 and bag filter 7, the hammer mill 2 is arranged on the top of the sealed bin 3, the jaw crusher 1 is arranged above the hammer mill 2, the collection bin 4 is funnel-shaped, sealed The bin 3 is cylindrical, and the collecting bin 4 is arranged in the sealed bin 3, and the sealed bin 3 is provided with an air suction hole along the tangent direction of the cylindrical surface, and the air suction hole is connected with the Shacron dust collector 5. The inlet is connected, the outlet of the Shacron dust collector 5 is connected with the inlet of the fan 6 , and the outlet of the fan 6 is connected with the inlet of the bag filter 7 .

[0028] Wherein the sealing bin 3 has a door, which is convenient f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap