Guiding mechanism for LED punching machine

A technology of guiding mechanism and punching machine, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of warping deformation, incorrect position of LED bracket, no guiding mechanism of LED punching machine, etc., to achieve convenient docking, punching, etc. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

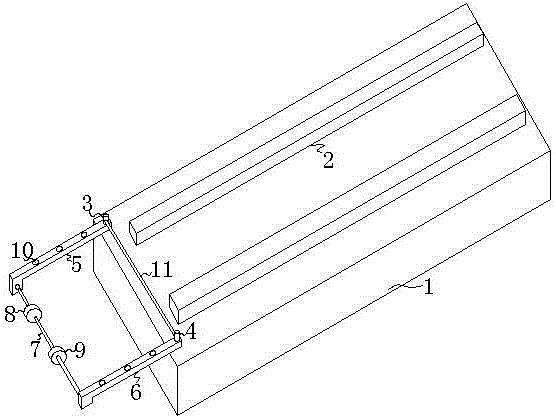

[0011] Such as figure 1 As shown, the present invention includes a base 1 and a guide rail 2 affixed to the base, and the end of the outer base of the guide rail away from the stamping machine is movably connected with a horizontally rotatable left support rod through a left rotating shaft 3 and a right rotating shaft 4 respectively. 5 and the right support rod 6, the left support rod and the right support rod are symmetrical about the central axis of the base, and the ends of the left support rod and the right support rod are connected by a roller shaft 7, which is sleeved on the base The left limiter 8 and the right limiter 9 are symmetrically distributed in the center of the seat.

[0012] The base in the present invention is fixedly connected to the inlet end of the LED punching machine, and the guide rails include two guide rails that are symmetrical about the ce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap