Rotary ultrasonic machining device based on non-contact energy transfer

An energy transmission, rotating ultrasonic technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of inability to realize automatic tool change, fast carbon brush wear, low tool speed, etc., to improve processing efficiency and Effect of machined surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

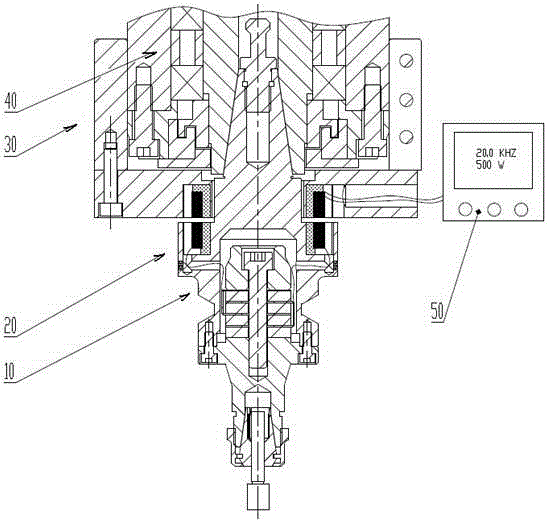

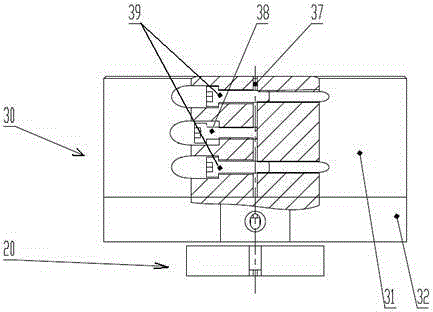

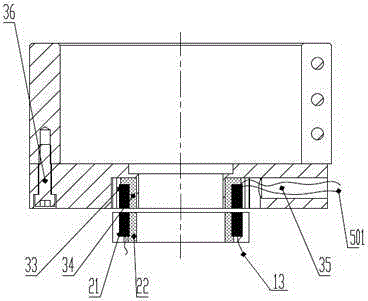

[0019] Preferred embodiments of the present invention are figure 1 As shown, it includes a high-speed electric spindle 40, a primary assembly 30 fixed at the lower end of the high-speed electric spindle 40, an ultrasonic handle assembly composed of an ultrasonic handle 10 and a secondary assembly 20 arranged around the ultrasonic handle 10, and an ultrasonic power generator. device 50; the ultrasonic tool handle assembly is installed on the lower end of the high-speed electric spindle 40 so that the secondary side assembly 20 is axially corresponding to the primary side assembly 30, and the ultrasonic power generator 50 is connected to the primary side assembly 30 connections.

[0020] The high-speed electric spindle 40 has a spindle speed of 10000-40000r / min and a dynamic balance of G0.4; the output power frequency of the ultrasonic power generator is about 20KHZ, and the power is 200-1000W, and the power is continuously adjustable; Or behind the tool, the overhang length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com