Anti-static woven tape

An anti-static and anti-static layer technology, applied in the field of webbing, can solve the problems of easy disappearance of anti-static effect, and achieve the effects of reducing the amount of static charge generated, high anti-static performance, and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

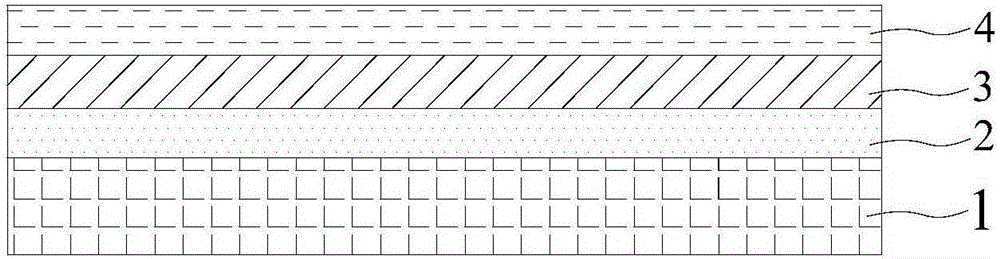

[0020] The antistatic ribbon of the present embodiment comprises a ribbon body, the ribbon body includes a ribbon layer 1 and two groups of composite functional layers, the composite functional layer is arranged on the surface of the ribbon layer 1, the surface of the ribbon layer 1 includes a first surface and is opposite to the first surface The second surface of the first surface and the second surface are respectively provided with a group of composite functional layers. In order to clearly and concisely illustrate the ribbon structure of this embodiment, figure 1 In order to only arrange a group of composite functional layers on the first surface, the composite functional layers arranged on the second surface and figure 1 The composite functional layers shown arranged on the first surface are arranged symmetrically.

[0021] Such as figure 1 As shown, each group of composite functional layers includes a first wear-resistant layer 2, a second wear-resistant layer 3 and an...

Embodiment 2

[0025] The webbing of this implementation differs from Example 1 in that: the webbing layer is woven with at least one antistatic warp thread every 5 mm, and the webbing layer is woven with at least one antistatic weft thread every 2 mm. The antistatic warp thread and the antistatic weft thread are respectively carbon fiber.

[0026] The webbing in Example 1 already has a certain anti-static function, but the webbing layer of this embodiment is woven with carbon fibers, which further enhances the anti-static effect of the webbing. In addition, if the electrostatic layer is damaged during long-term use and loses the anti-static function, because the webbing layer is woven with carbon fiber, the worn webbing also has anti-static function.

Embodiment 3

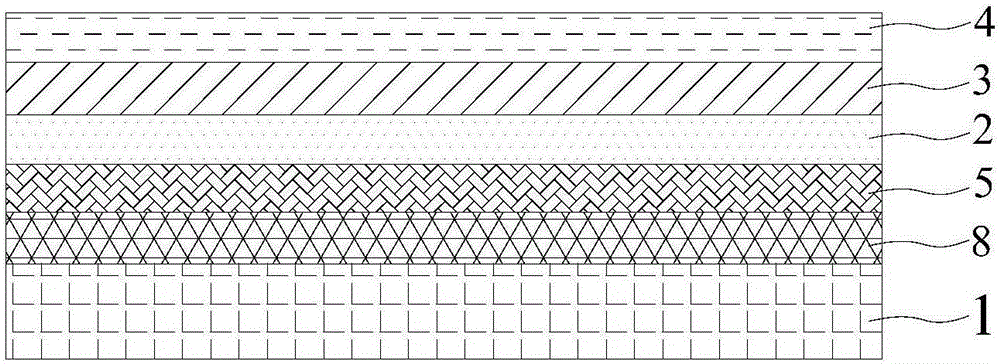

[0028] The webbing of the present embodiment differs from Embodiment 1 in that: as figure 2 As shown, the composite functional layer also includes a first oxygen barrier layer 5 woven from alkali-free glass filaments and ceramic fibers, and the first oxygen barrier layer 5 is arranged between the first wear-resistant layer 2 and the surface of the webbing layer 1 .

[0029] In addition, the composite functional layer of this embodiment also includes an anti-mold layer 8, which is located between the first oxygen barrier layer 5 and the surface of the webbing layer 1, and the anti-mold layer 8 is embedded with bamboo charcoal fiber filaments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com