Tire engine

A technology of engines and tires, applied in auxiliary drive devices, control devices, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

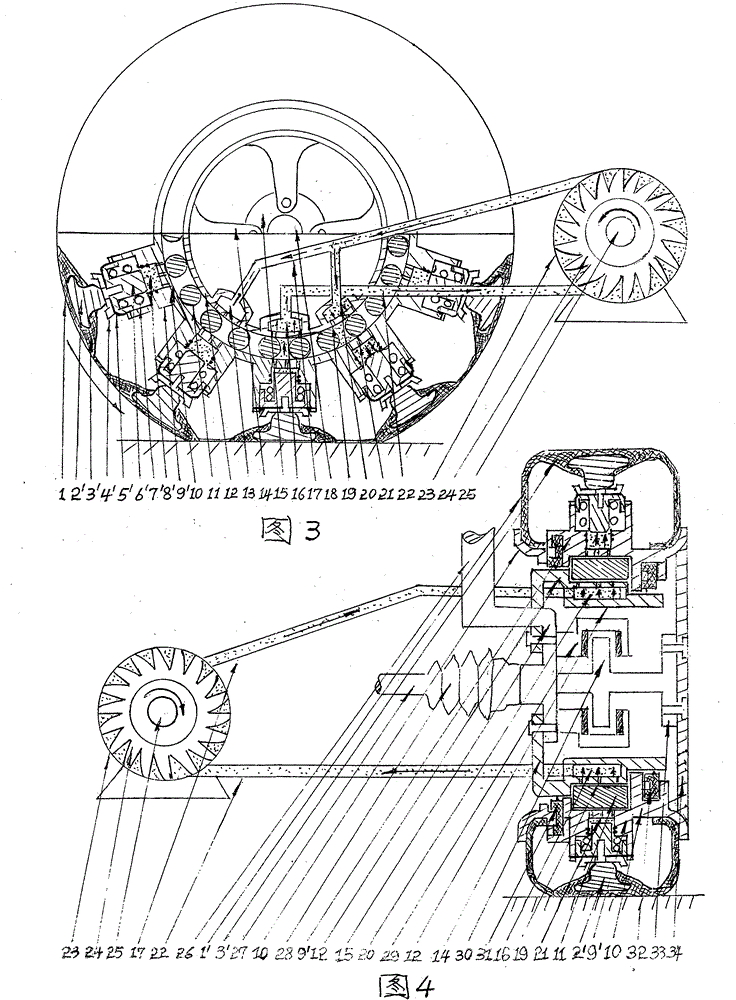

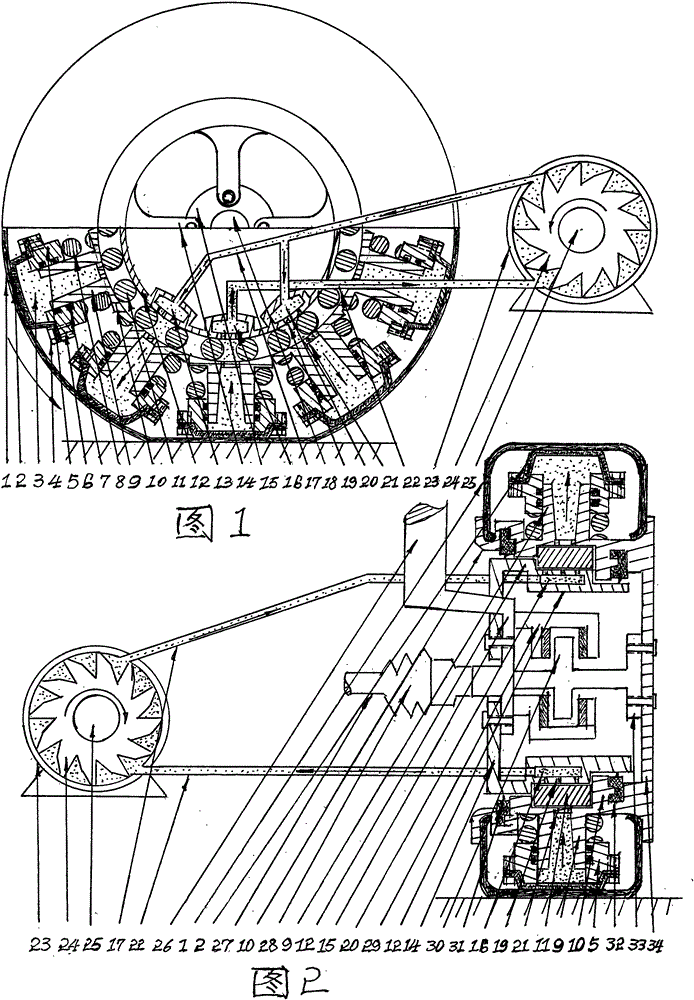

[0015] First install the drive shaft 27, universal joint 28, shock absorber 26, connecting plate 15, brake assembly 29, brake disc 30, and drive disc 33 of the original car, and then install the buffer tray on the sleeve 9 of the wheel hub 10 5. The buffer spring 8 sits on the upper end of the tray. The inner diameter of the tray is equipped with a sealing rubber ring 7 connected to the sleeve 9. The lower end of the tray presses the oil-resistant rubber tire 2 with the gland 4 through the bolt 6, and then installs the tire 1 on the On the rotating hub 10, if the hub of the nail-resistant stone road surface is installed, the piston 6', spring 7', diaphragm 5', and pressure plate 4' in the sleeve on the rotating hub 10 are installed, and then the push rod is installed. The tire 1 of 2′ is mounted on the rotating hub 10, and the rotating hub 10 is equipped with rolling steel balls 11, front oil seal 31 and rear oil seal 32. At this time, the fixed hub 12 and the rotating hub 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com