A slotting and glue-coating sealing process for building formwork

A technology for building formwork and gluing, which is applied in the on-site preparation of building components, construction, and formwork treatment to achieve the effects of extending service life, improving work efficiency and economic benefits, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

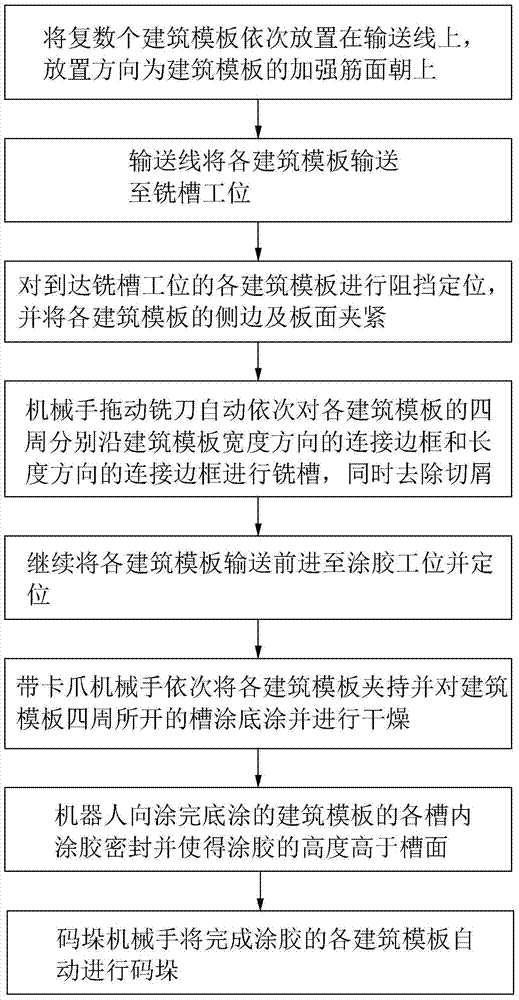

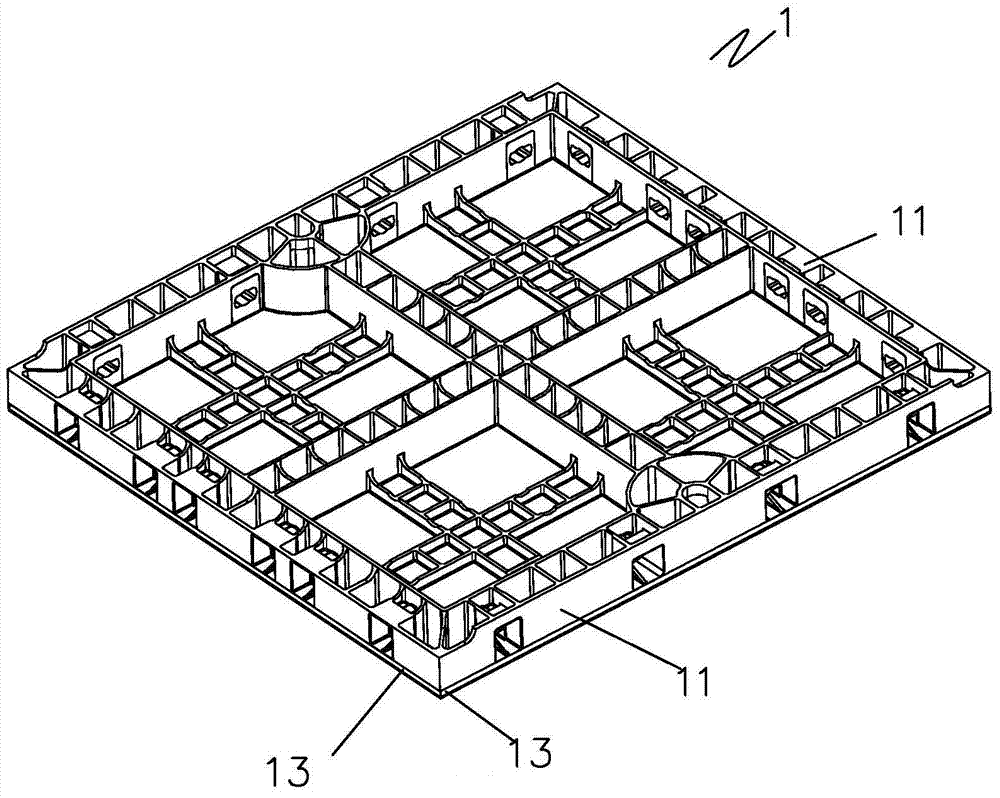

[0024] see figure 1 , a slotting and glue-coating sealing process of a building formwork of the present invention, comprising:

[0025] Step 10. Place a plurality of building formworks on the conveying line in turn, with the reinforcing ribs of the building formworks facing upwards (formworks of different specifications can be placed on the conveying line at the same time, generally meeting the requirements of all types with a width of 200-600mm, 600, 1200 or 1800mm in length and different thicknesses of building formwork for slotting and gluing);

[0026] Step 20, the conveying line transports each of the building templates to the slot milling station;

[0027] Step 30, blocking and positioning each of the building formworks arriving at the milling station, and clamping the sides and panels of each of the building formworks;

[0028] Step 40, the manipulator drags the milling cutter to automatically mill grooves around the connection frame in the width direction of the buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com