Air pressure power device for underwater spontaneous starting and spontaneous starting method

A pneumatic power and self-starting technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of out of control of pneumatic and safety control components, failure of transmission mechanism, failure to work, etc., to improve personal safety factor, reduce economic losses, The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

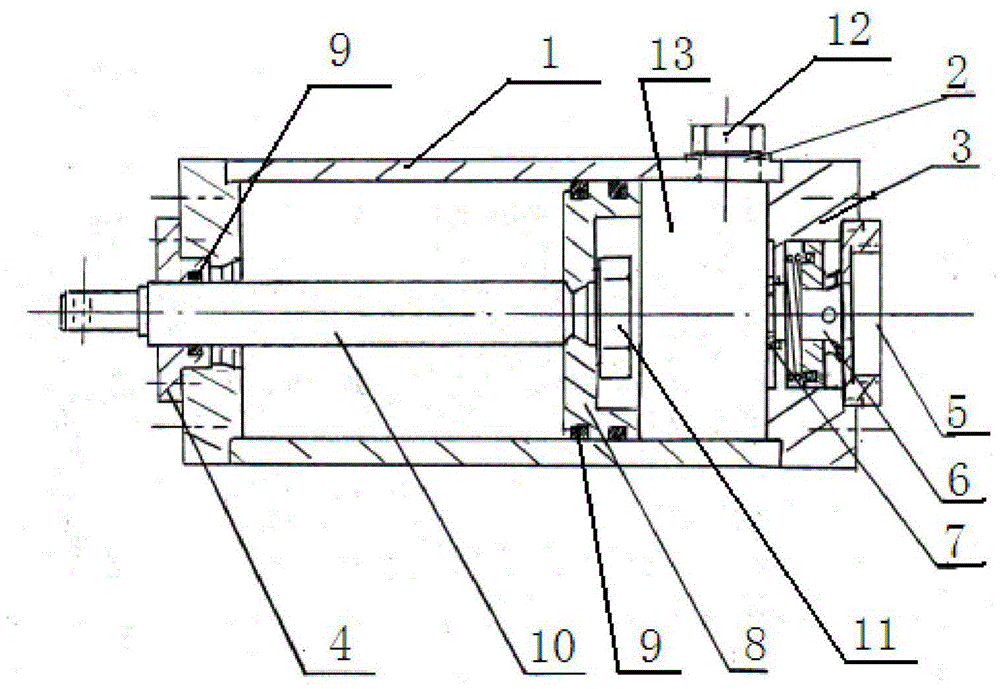

[0033] Relevant material and performance index requirements: cylinder body 1, active (passive) cover plate 3 (4), piston 8, piston rod 10, plug or valve 12, check valve 6 and filter screen 5, filter sheet 7, assembly Bolts, nuts, elastic washers, etc. are all made of nickel-chromium alloy; the sealing ring 9 is made of a high-pressure resistant sealing ring.

[0034] Sectional ratio of piston 8 to piston rod 10: 80:1;

[0035] Inner diameter of cylinder body 1: 100mm;

[0036] Total length of cylinder body 1: 300mm;

[0037] Piston rod 10 length: 300mm;

[0038] Piston 8 thickness: 30mm; Piston 8 diameter: 99.2mm;

[0039] Allowable compressive strength of cylinder wall 1: 10MPa;

[0040] Working pressure of piston rod 10: 10MPa, stroke: 120mm;

[0041] Automatic opening time: 3s.

[0042] The charging port 2 of the power gas source part 13 is provided with screw threads, and 1kg of rubidium peroxide is filled in the power gas source part 13, and the charging port 2 is t...

Embodiment example 2

[0044] Relevant material and performance index requirements: cylinder body 1, active (passive) cover plate 3 (4), piston 8, piston rod 10, plug or valve 12, check valve 6 and filter screen 5, filter sheet 7, assembly Bolts, nuts, elastic washers, etc. are all made of high-strength corrosion-resistant steel; the sealing ring 9 is made of a high-pressure resistant sealing ring.

[0045] Sectional ratio of piston 8 to piston rod 10: 100:1;

[0046] Inner diameter of cylinder body 1: 300mm;

[0047] Total length of cylinder 1: 1000mm;

[0048] Piston rod 10 length: 1000mm;

[0049] Piston 8 thickness: 80mm; Piston 8 diameter: 299.2mm;

[0050] Allowable compressive strength of cylinder wall 1: 30MPa;

[0051] Working pressure of piston rod 10: 30MPa, stroke: 150mm;

[0052] Automatic opening time: 5s.

[0053] Valves are installed at the charging port 2 of the power gas source part 13, and 5kg of sodium peroxide is filled in the power gas source part 13, and the refined feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com